Basement external wall post-cast strip construction method and building structure thereof

A technology for basement exterior walls and construction methods, which is applied to underwater structures, buildings, infrastructure projects, etc., can solve problems such as affecting the progress and quality of construction, waste of building materials, and increased construction costs, so as to eliminate potential safety hazards. , The effect of reducing construction costs and speeding up the progress of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

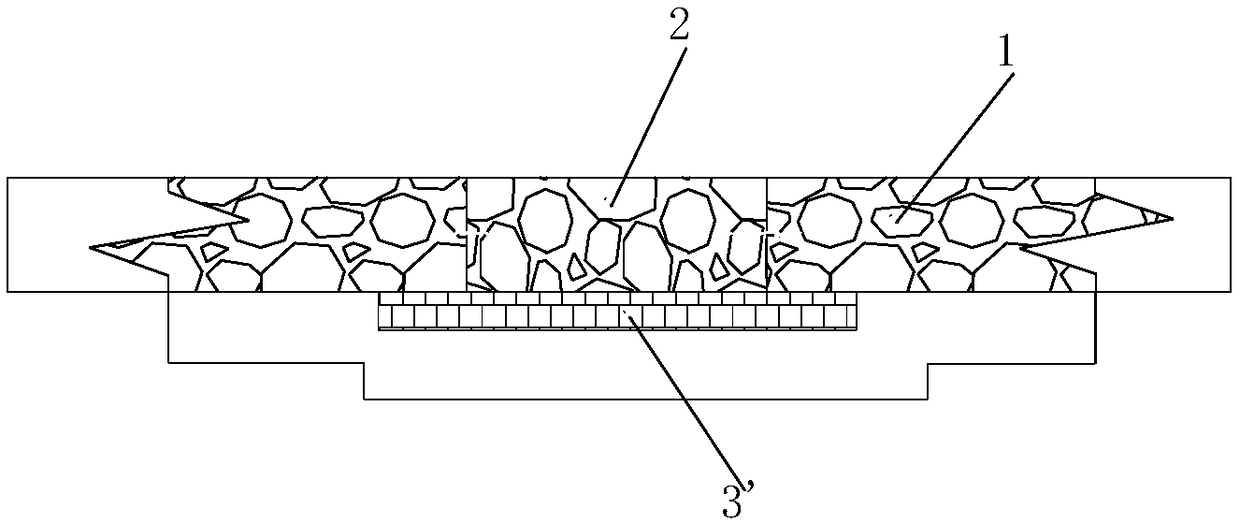

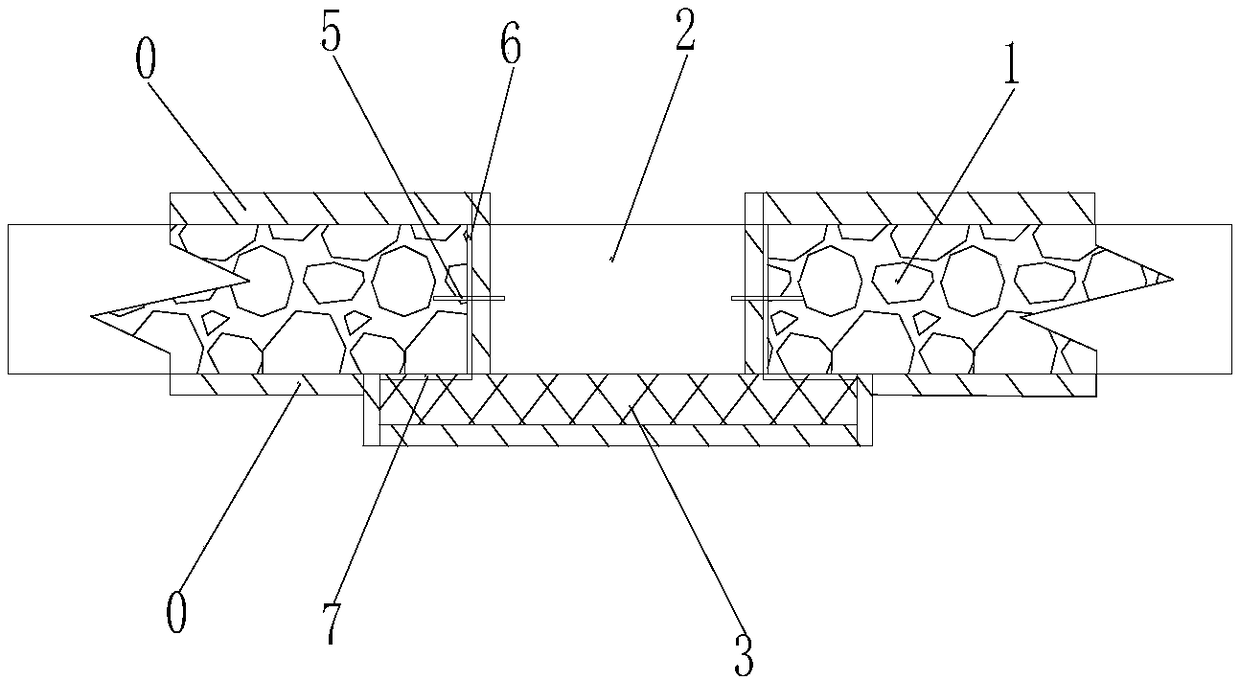

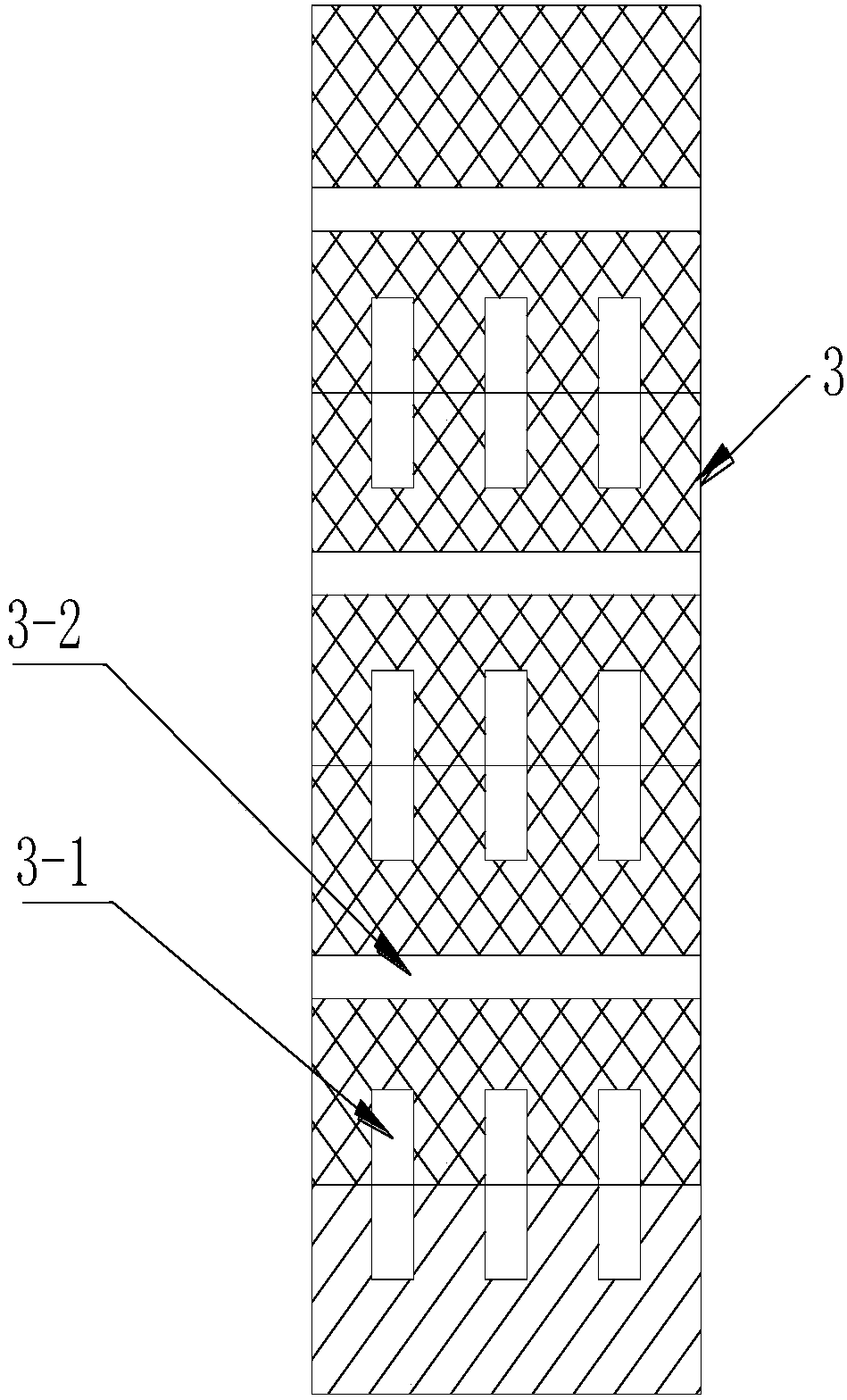

[0121] like Figure 2 to Figure 3 As shown in the figure, this embodiment provides a construction method of a back-casting belt for a basement exterior wall. When pouring the outer wall 1, a guide wall 3 is poured on the outer side of the back-casting belt 2, and the material of the guide wall 3 is a pouring wall. waste produced during the construction and / or leftovers after the wall has been poured.

[0122] In this embodiment, when the outer wall is poured, the guide wall is poured on the outer side of the post-casting belt, and the material of the guide wall is the waste generated when the wall is poured and / or the residual material left after the wall is poured. Therefore, this construction method greatly speeds up the construction progress and improves the quality of the project. Due to the high strength of the guide wall, even under the action of backfill earth pressure, the guide wall is not easy to collapse, eliminating potential safety hazards. There is no need to pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com