Defect detection method of underground diaphragm wall based on partitioned ultrasonic tomography

An underground diaphragm wall and defect detection technology, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of fracture, blockage, small data volume, etc., achieve wide data coverage, improve detection efficiency, and collect data volume big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

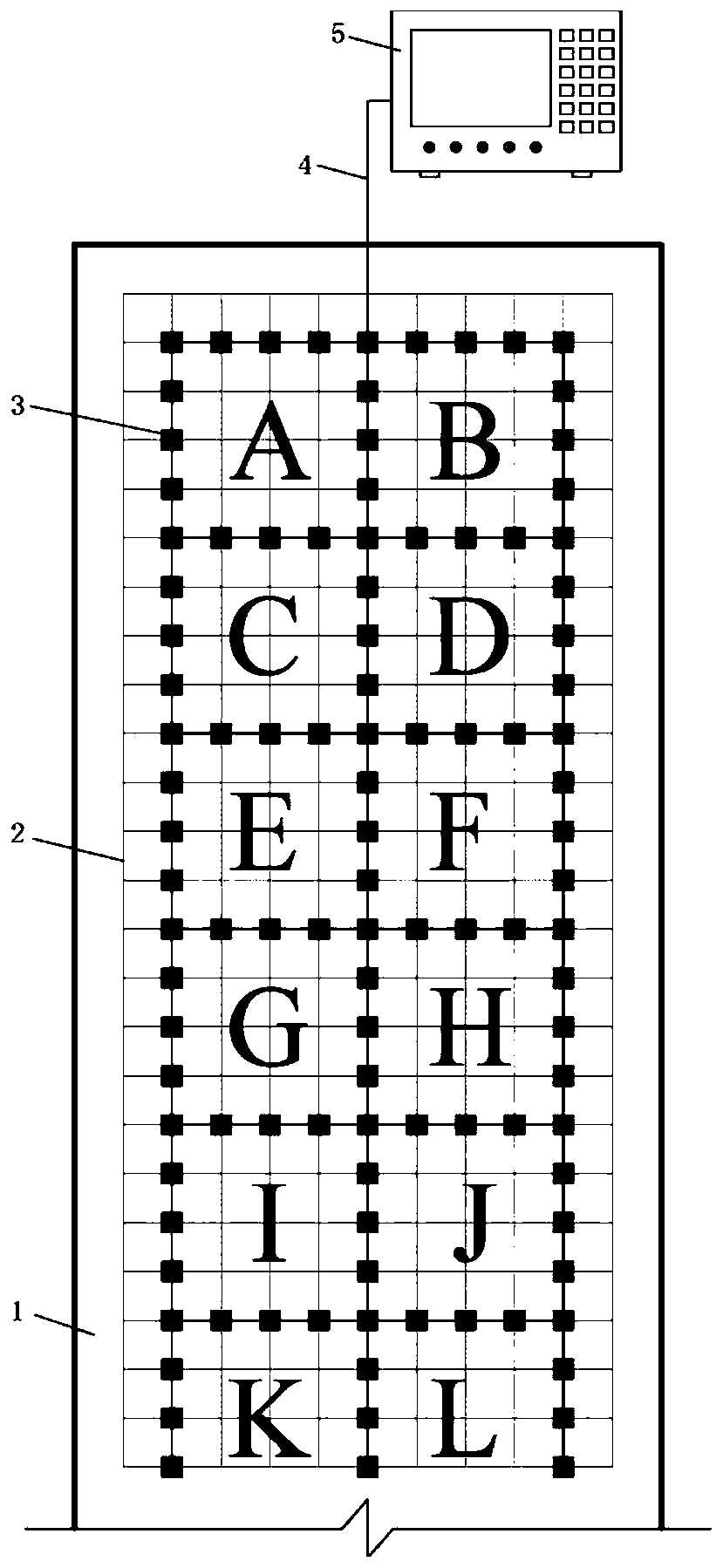

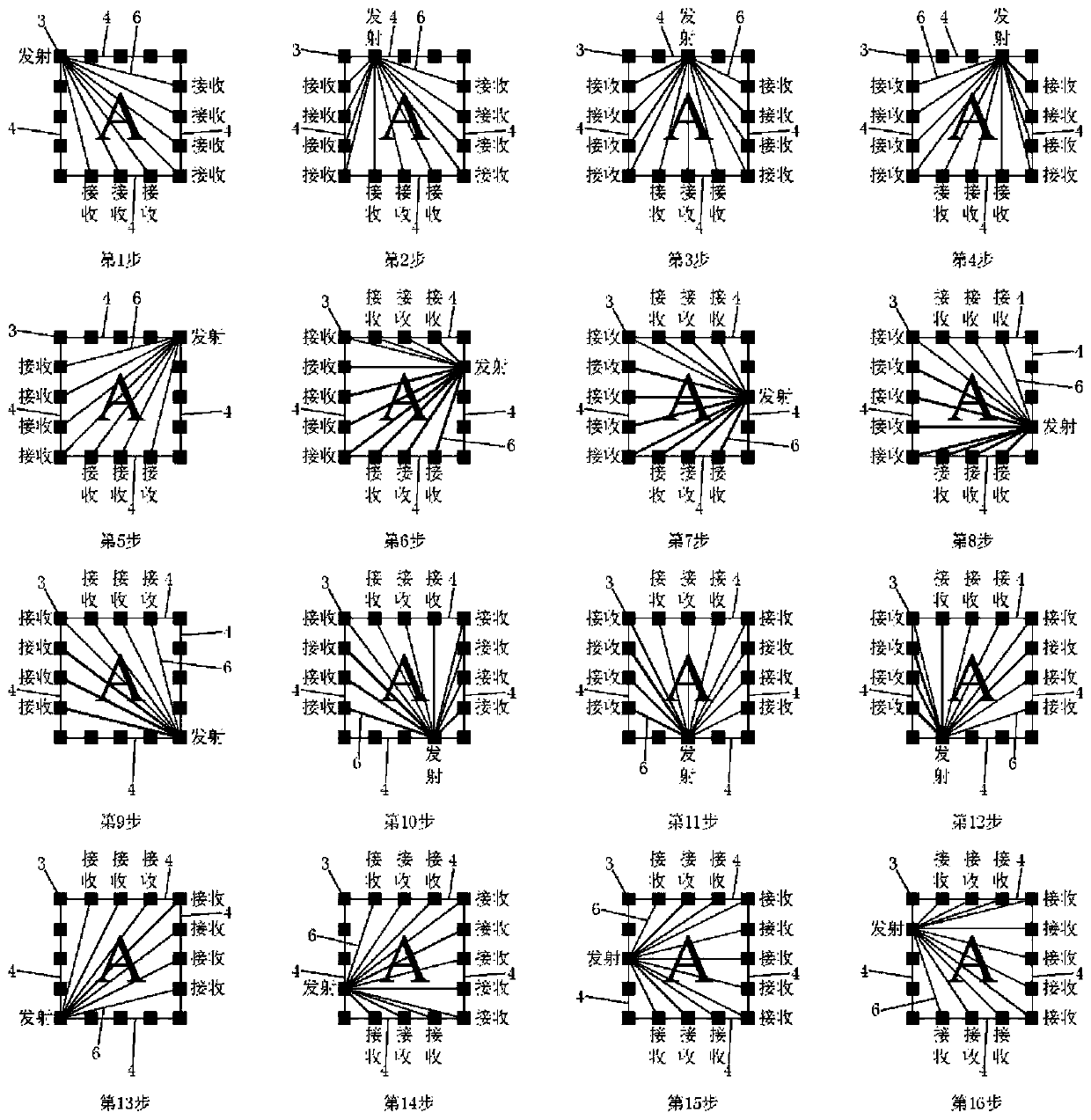

[0016] refer to Figure 1-2 The method for detecting defects in an underground diaphragm wall based on subregional ultrasonic tomography provided in this embodiment includes the following steps:

[0017] (1) Divide the underground diaphragm wall 1 to be poured into grid-like rectangular detection areas, and number these rectangular areas as A, B, C, etc., and the size of the rectangular areas is comprehensively determined according to the ultrasonic penetration ability and the size of the underground diaphragm wall.

[0018] (2) After the reinforcement cage 2 of the underground diaphragm wall 1 is bound, several ultrasonic sensors 3 are arranged on the edge of the reinforcement cage 2 corresponding to the rectangular area divided in (1). These ultrasonic sensors 3 are located in the middle thickness plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com