Modular structure of integrated wall surface and installation method

An installation method and modular technology, applied in building construction, covering/lining, construction, etc., can solve the problems of time-consuming operation, non-parallel buckle position, inaccuracy, etc., to reduce the difficulty factor of installation operation and reduce labor intensity , The effect of simplifying the installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

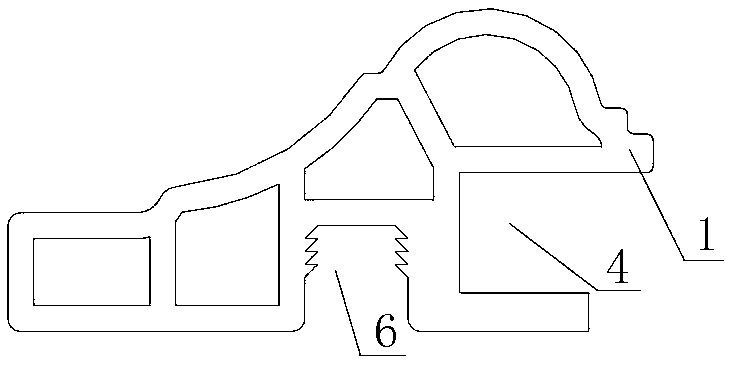

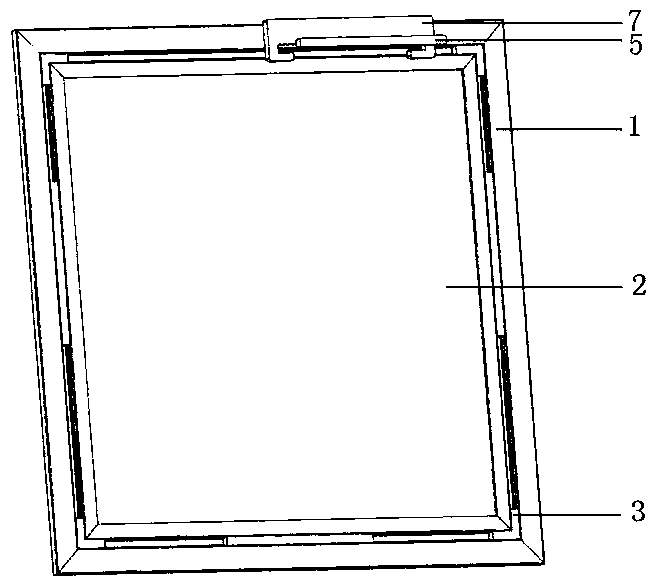

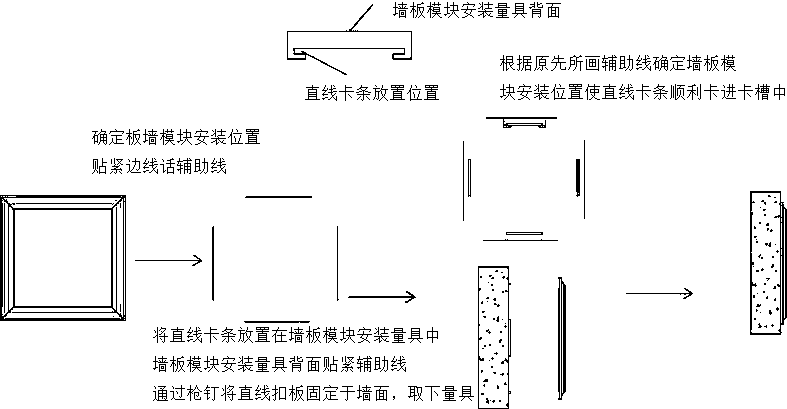

[0021] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-7 As shown, a modular structure of an integrated wall according to the present invention is mainly composed of a wall panel module, a straight line clip and a wall panel module installation measuring tool; the wall panel module is composed of four frame lines 1, one The whole module assembled by wallboard 2 and four right-angle corner codes 3; the frame wire 1 has a U-shaped groove 4 on one side of its cross section to clamp the wall board 2, and on the back of the frame wire 1 there is a Both the right-angle corner code 3 and the straight clip 5 can form an interference-fitted, toothed slot 6; the thickness of the wallboard 2 just forms a clearance fit with the U-shaped slot 4 on the side of the frame line 1; The linear clip 5 is a cubic clip, which can form an interference fit with the toothed slot 6 on the back side of the frame line 1; the wall panel module in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com