Fabricated toilet and installation method thereof

A prefabricated, toilet technology, applied in water supply installations, building components, sewer pipe systems, etc., can solve the problems of complex installation and decoration procedures, long installation time, and high installation costs, reducing material costs, upstairs and downstairs interference. The effect of less and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] The present invention will be further explained below in conjunction with the drawings and embodiments:

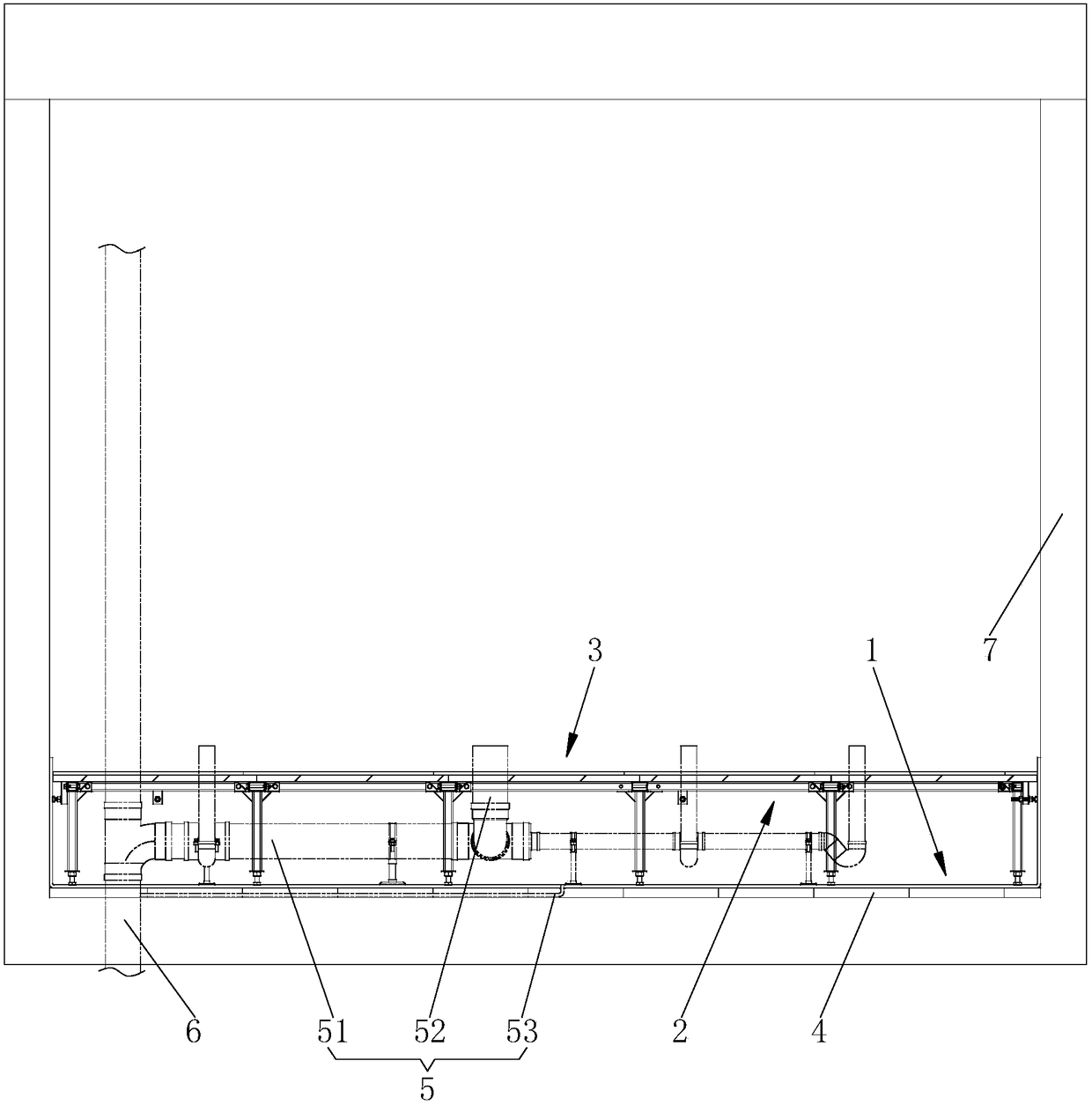

[0053] Such as figure 1 As shown, a prefabricated toilet in this embodiment has a leveling cushion 4, a flexible waterproof tray 1, a steel frame 2, a same-layer drain pipe 5, and a fabricated floor 3. The above-mentioned leveling cushion 4, a flexible waterproof tray 1. The steel frame 2, the same-layer drain pipe 5 and the fabricated floor 3 are all set in the bathroom 7.

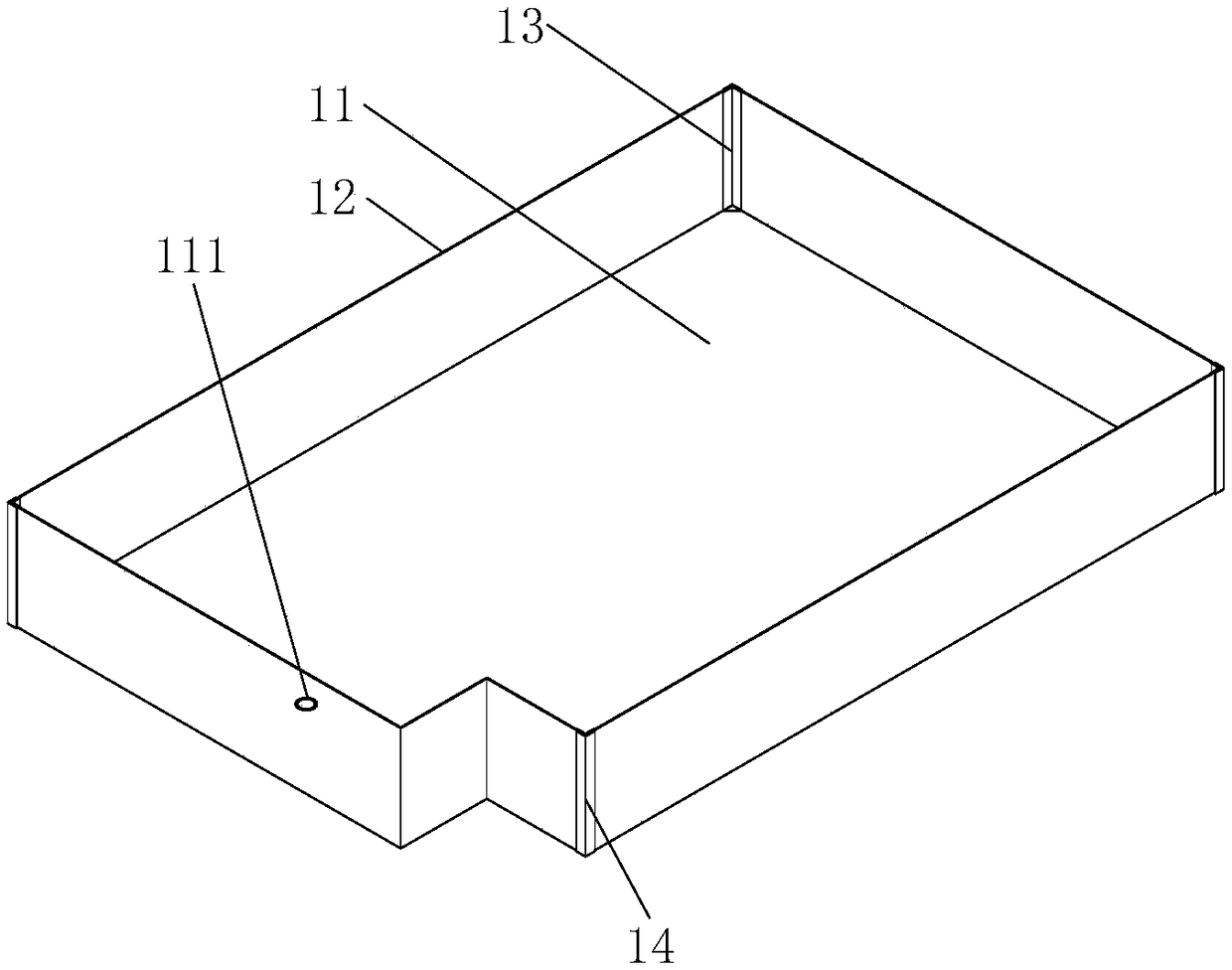

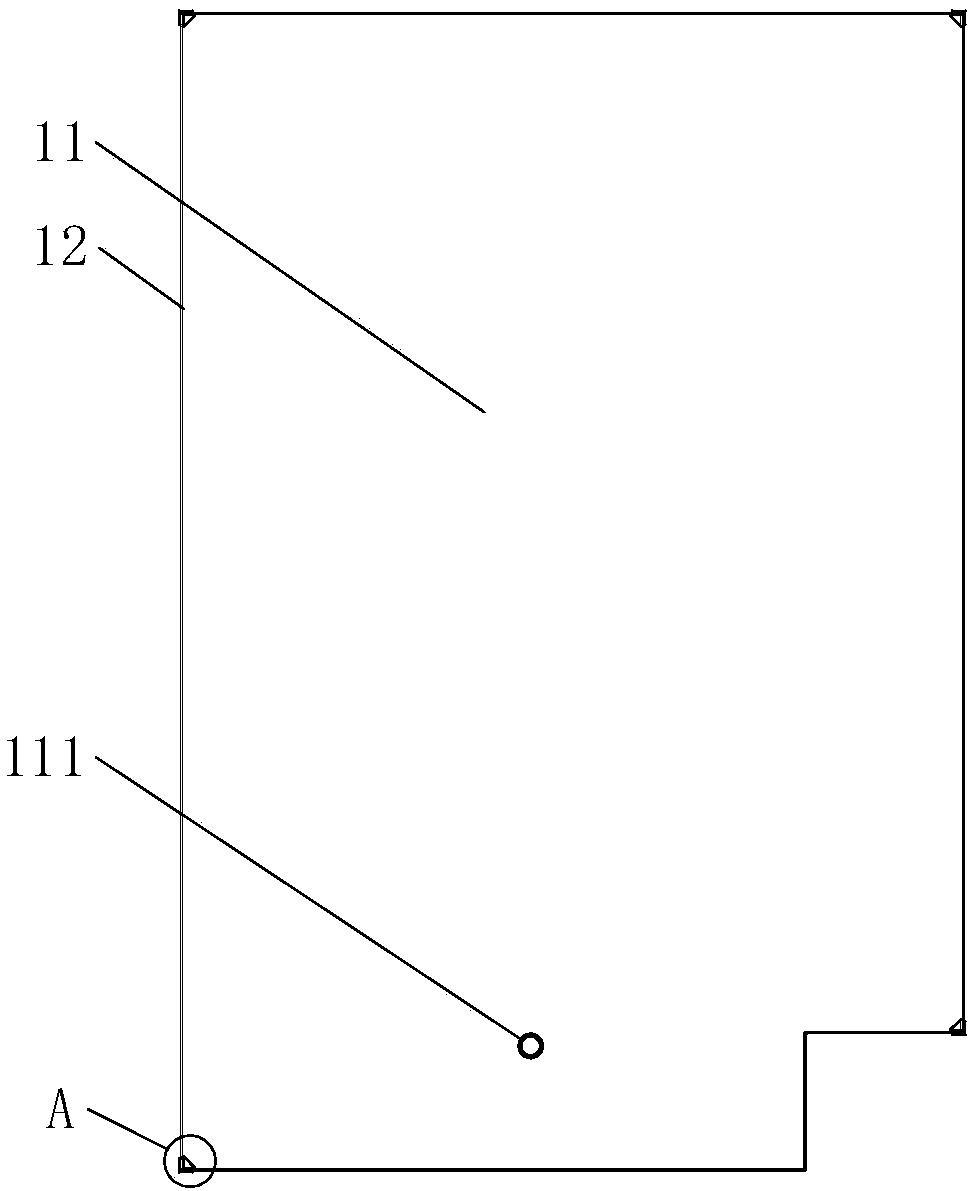

[0054] Such as figure 1 with figure 2 As shown, in this embodiment, the leveling cushion 4 is arranged on the upper surface of the toilet 7, and the flexible waterproof plate 1 is arranged on the upper side of the leveling cushion 2. The flexible waterproof plate 1 includes a waterproof bottom plate 11 and a waterproof vertical plate 12, which is waterproof The bottom plate 11 is horizontally arranged and has a rectangular shape with a notch in one corner. The waterproof bottom plate 11 is provided...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap