Upper air inlet furnace end capable of adjusting air intake

An adjustable and burner technology, which is applied to gas fuel burners, combustion methods, combustion types, etc., can solve problems such as Liyan or Hongyan, unstable gas source, and inability to adjust, so as to improve the mixing effect and improve the combustion Efficiency, the effect of preventing red fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

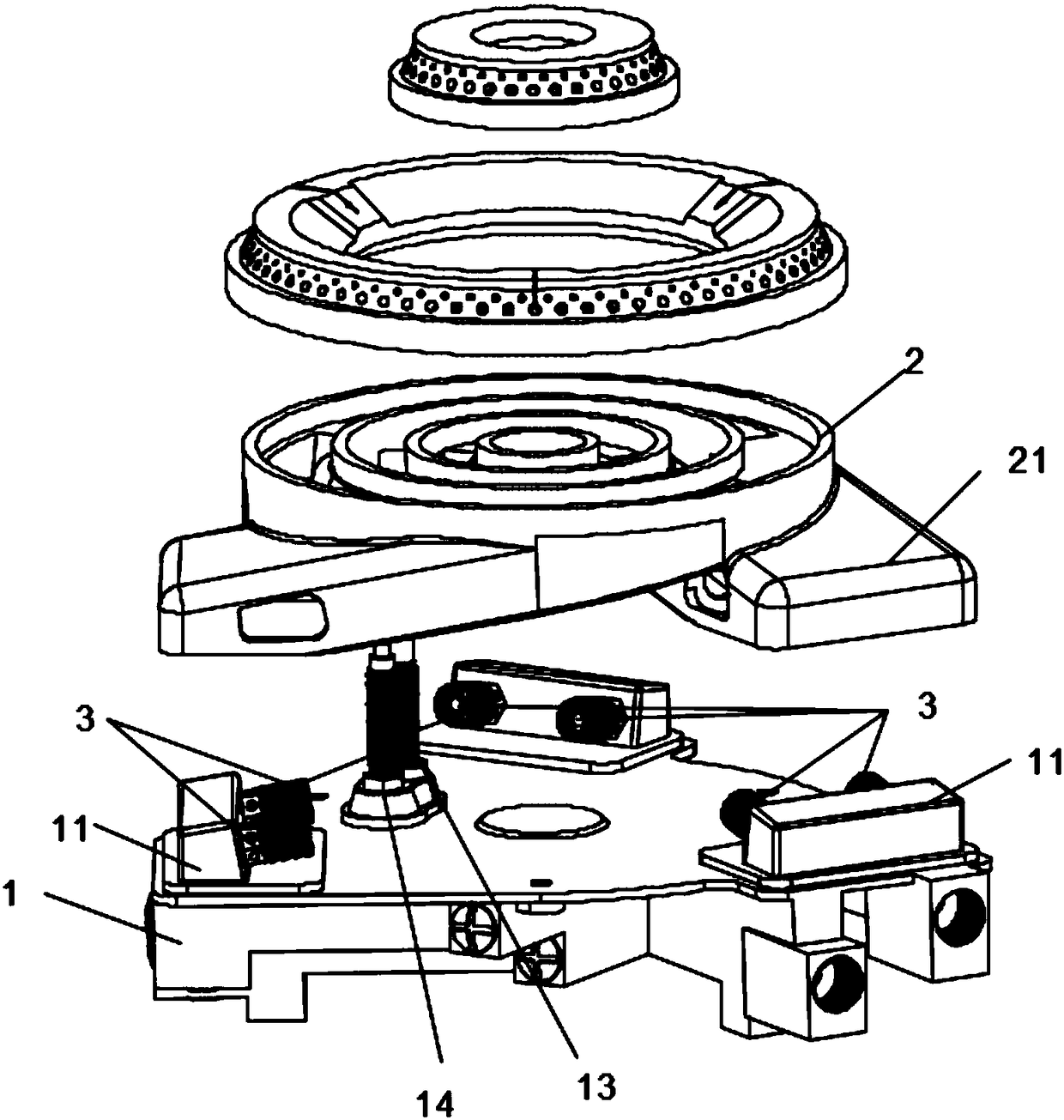

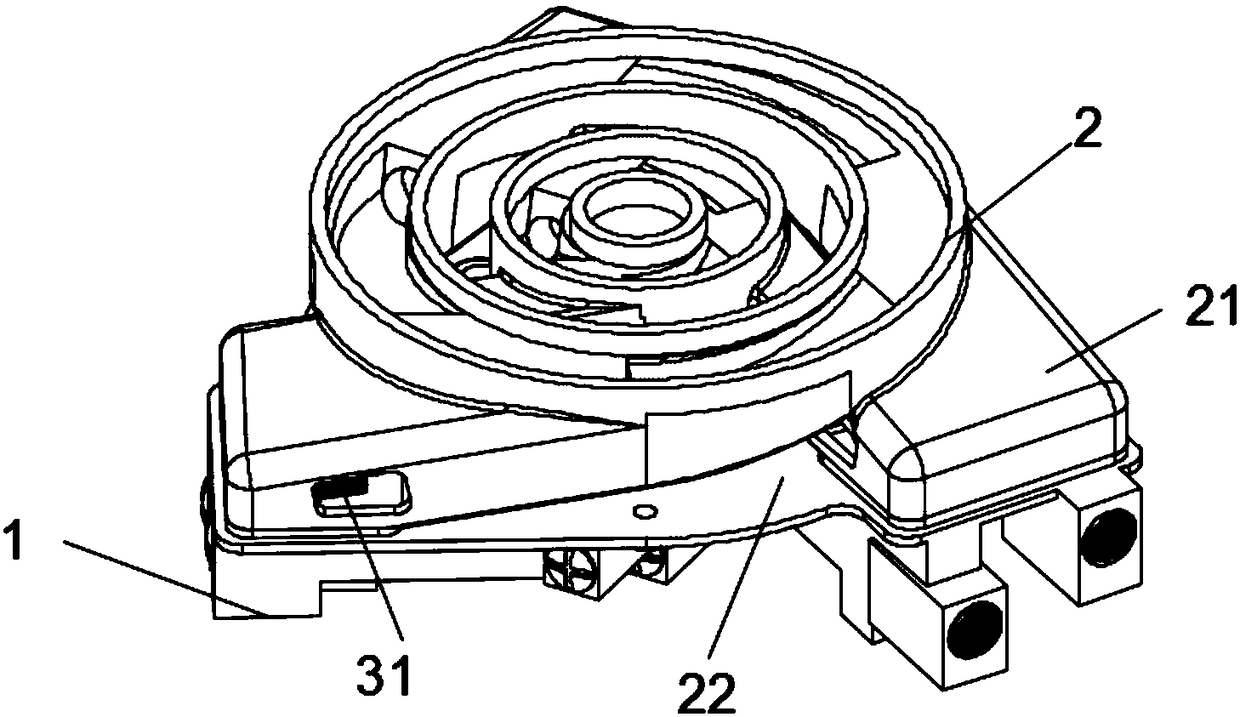

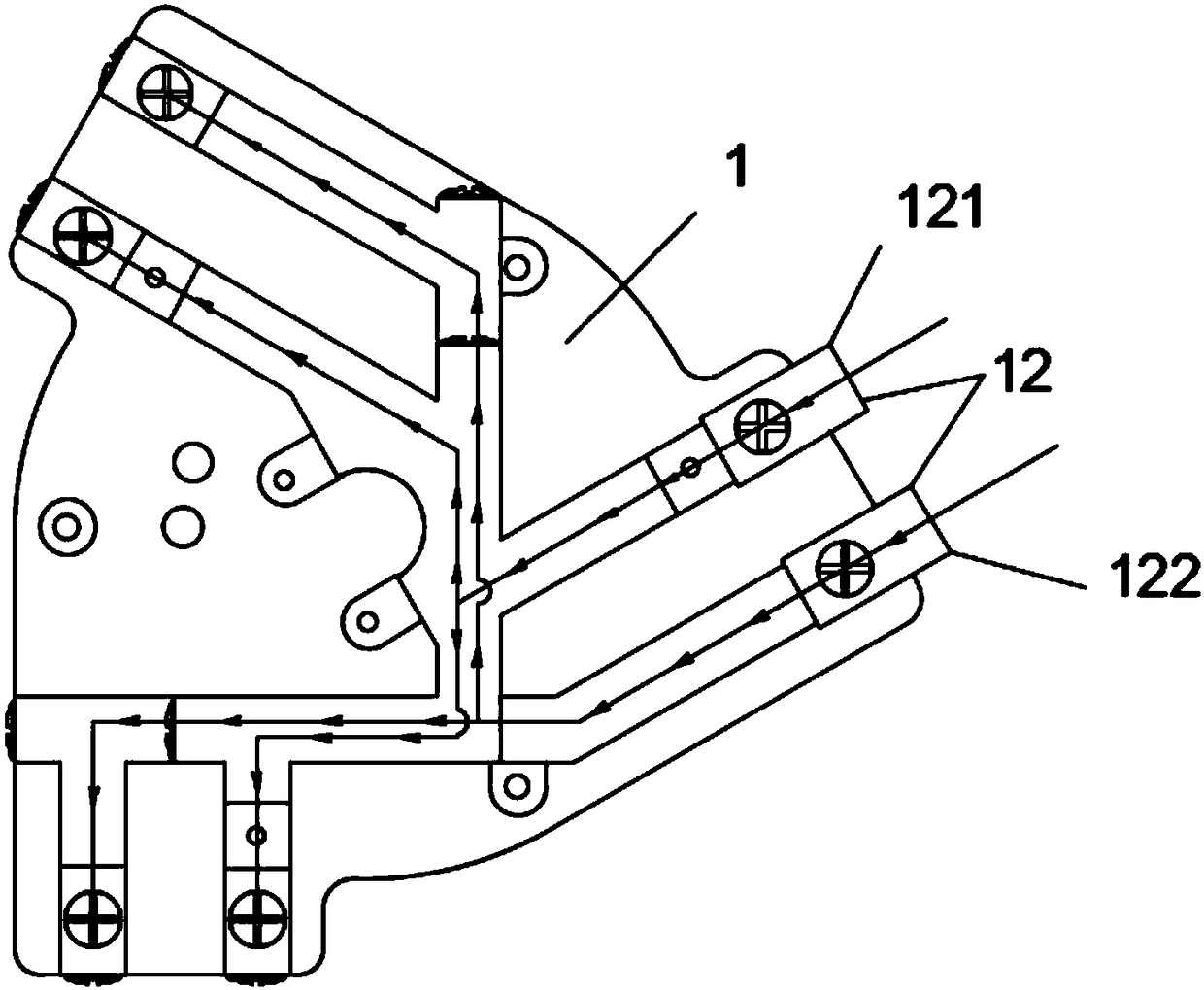

[0023] See attached Figure 1-7 , the present embodiment provides an upper air intake furnace head with adjustable air intake, including a furnace head lower part 1, a furnace head upper part 2 and a nozzle 3 arranged on the furnace head lower part 1, and the furnace head lower part 1 is respectively provided with There are several air intake pipes 12 and some air seats 11 communicating with the air intake pipes 12, double nozzles 3 are arranged on the air seats 11, and an air conditioning part 31 is arranged at one end of the nozzles 3, and the burner head The upper part 2 is provided with several ejection bridges 21 extending outwards connected to the air seat 11, and an air inlet 22 is provided below the ejection bridge 21 to provide sufficient air, and the ejection bridge 21 is provided with The central air passage 23 and the outer ring air passage 24 corresponding to the double nozzle 3, the outer ring air passage 24 communicates with the outer ring gas mixing chamber 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com