A Fatigue Test Bench for Inclined Coil Springs

A technology of inclined coil spring and fatigue test, which is applied in the direction of elasticity test, machine/structural component test, instrument, etc., can solve the problems of worn inclined coil spring, noise, measurement error, etc., and reduce friction and noise , the effect of reducing wear and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

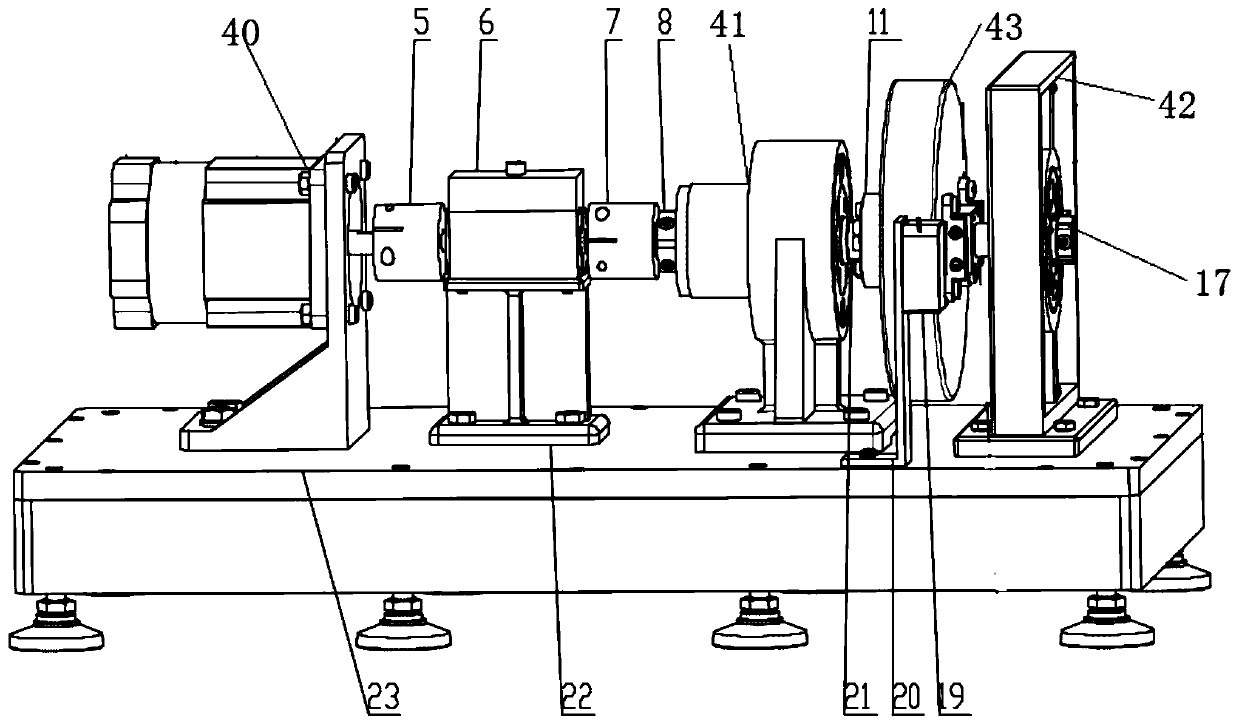

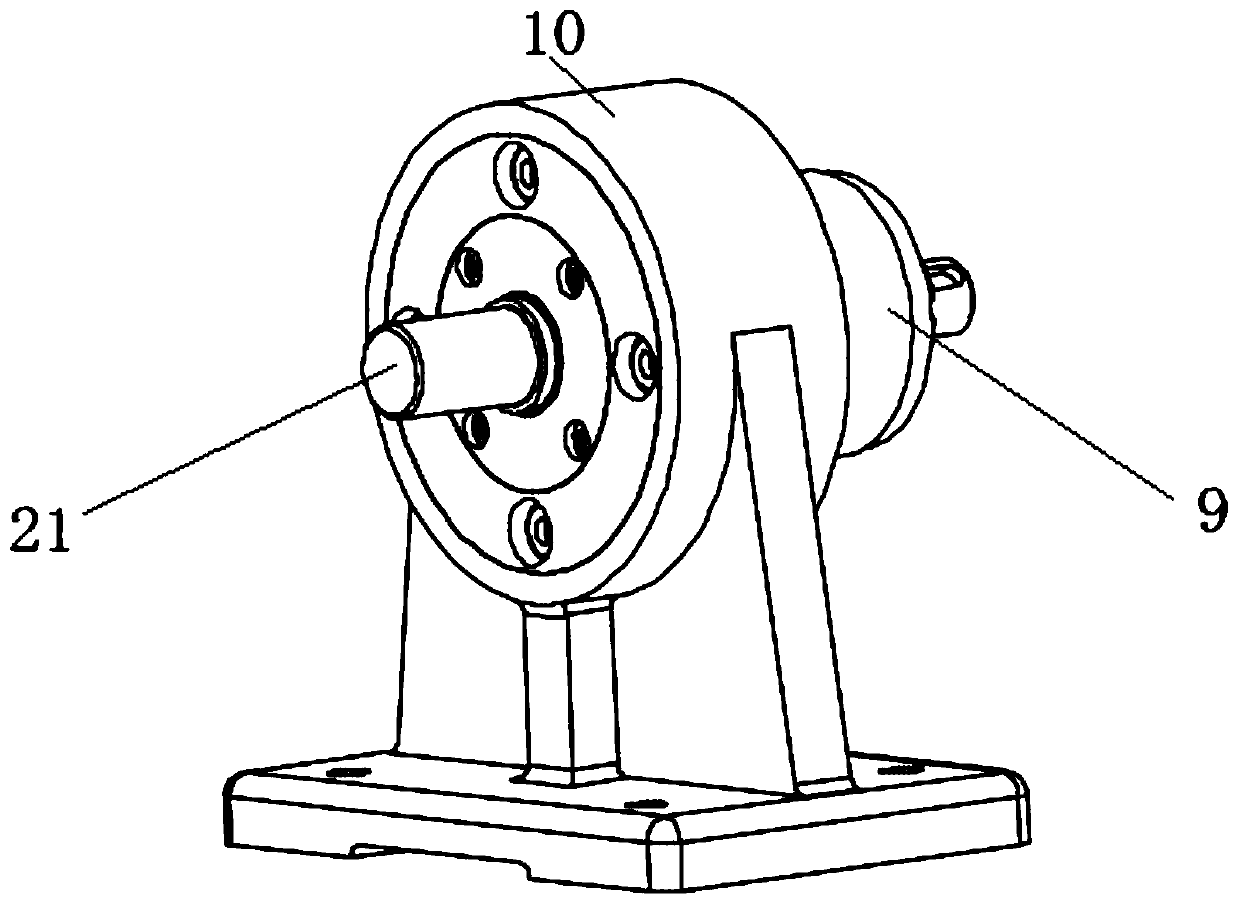

[0032] A kind of inclined coil spring fatigue test bench of the present invention, as figure 1 As shown, a canted coil spring fatigue test bench is characterized in that it includes a base 23, and the base 23 is fixed with a sequentially connected sensing device 40, a bearing assembly 41 and a clamping device 42 for clamping the spring to be tested , An eccentric shaft device 43 is connected between the bearing assembly 41 and the clamping device 42 .

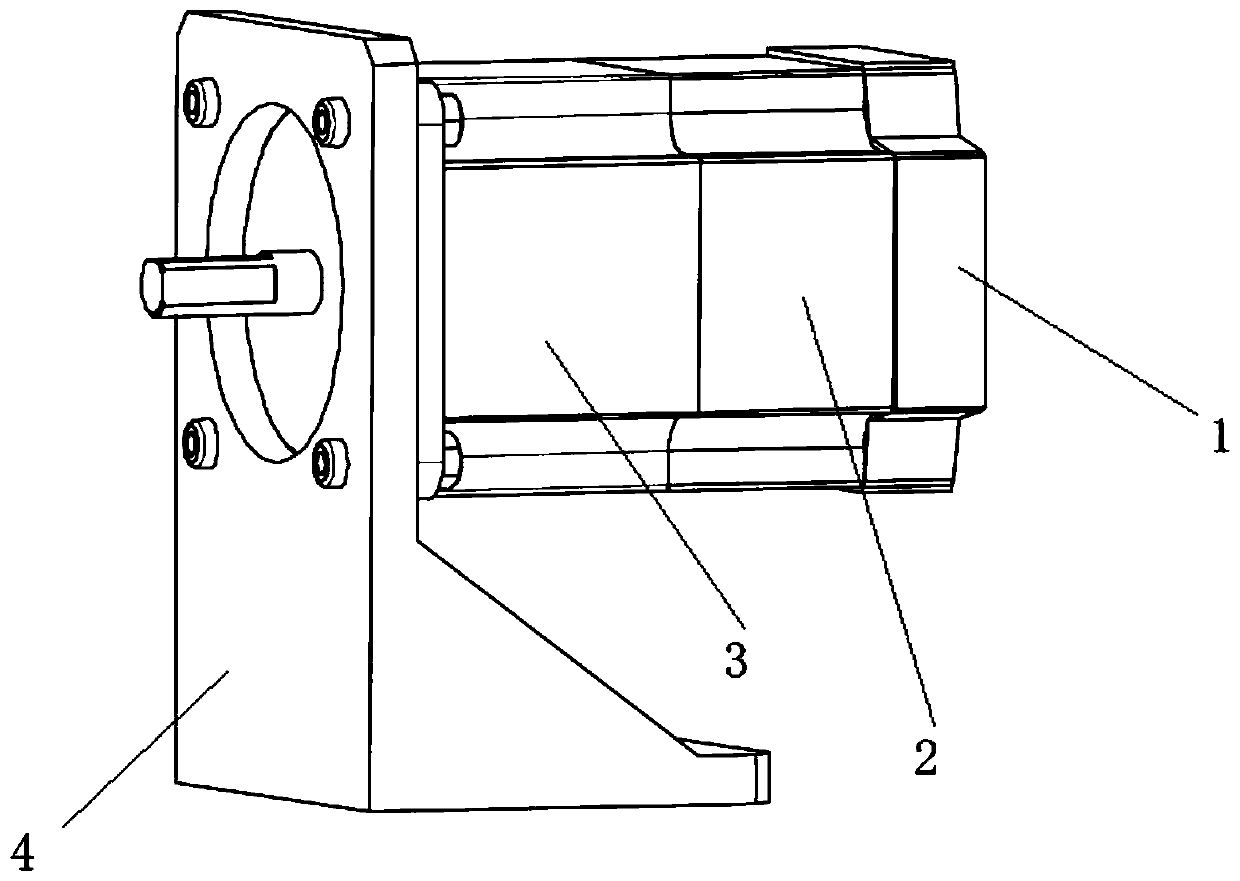

[0033] Such as figure 2 As shown, the sensing and detecting device 40 includes a rotary encoder 1, a brake 2, a stepper motor 3, and a torque sensor 6 connected in sequence, and the sensing and detecting device 1 also includes a laser distance sensor 19, and the laser distance sensor 19 is located at the eccentric shaft device 43 On one side, the laser distance sensor 19 is fixed on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com