Prediction method of pitting corrosion and spalling risk for elastoplastic contact fatigue of carburized hardened gears

A carburizing hardening and contact fatigue technology, applied in the field of fatigue failure risk prediction of mechanical parts, can solve problems such as difficulty in failure risk prediction, economic loss, variable multiaxial stress state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] As shown in Figure 6, the sample gear comes from the middle and gear pair of a megawatt-class wind turbine gearbox, and its failure probability is significantly higher than that of other gears in practical engineering applications.

[0057] The main parameters of the gear pair are as follows:

[0058]

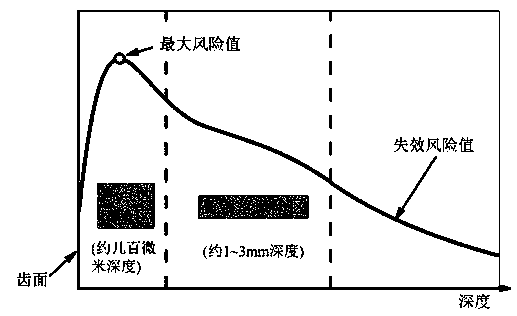

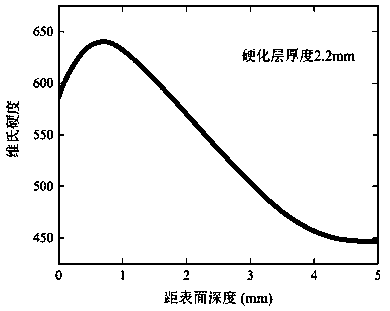

[0059] figure 2 is the fitting hardness curve corresponding to this sample, according to the gear parameters of the embodiment, taking the meshing instantaneous state at the node on the gear meshing line as an example, the fatigue aging risk value of the gear pair contact is gradually calculated:

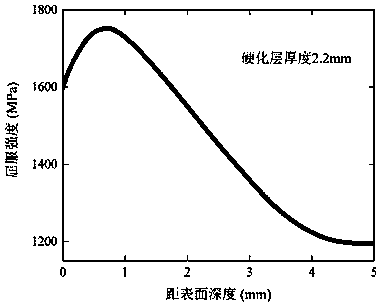

[0060] Step 1. According to the gear hardness curve and formula (2), the local yield strength of the gear material can be obtained, such as image 3 shown.

[0061] Step 2. Use Figure 4 The simplification shown reduces the meshing gears to a 2D contact model. According to formulas (3)~(4), by R 1 =236.28mm,R 2 = 44.18mm, the calculated comprehensive radius of curvat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com