Mirror-design double-sided zoom lens

A mirror and lens technology, applied in the field of double-sided zoom lenses, can solve the problems of small variable focus, insufficient wearing comfort, narrow zoom optical area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

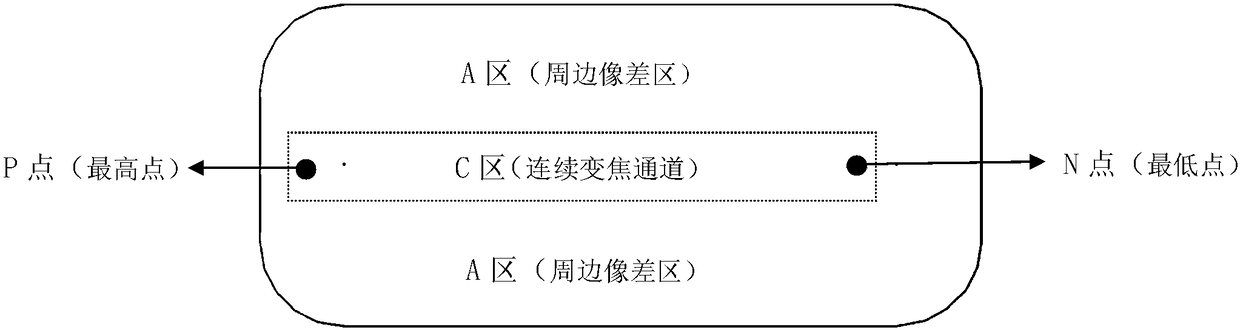

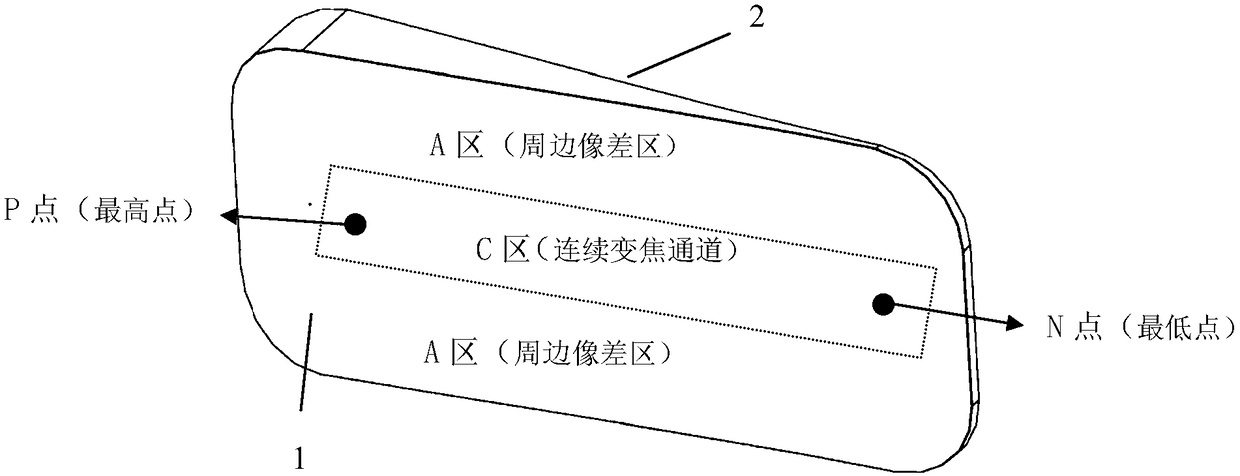

[0065] This embodiment provides a double-sided zoom lens with a mirror image design, including two symmetrical zoom surfaces with a mirror image design, Figure 1b As shown, one side is marked as A1 side, and the other side is marked as A2 side, such as Figure 1b as shown, Figure 1b Among them, 1 is the A1 side, and 2 is the A2 side.

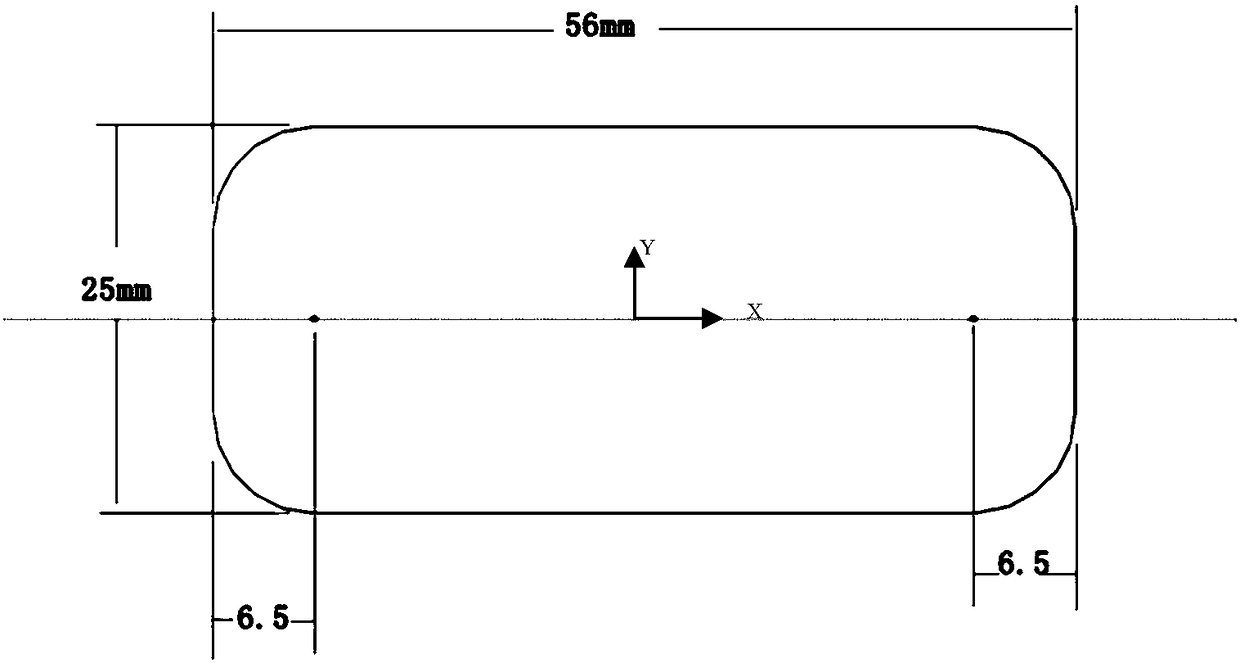

[0066] The zoom surface is a free-form surface. A freeform surface consists of a highest point and a lowest point. The wave-like change from the highest point to the lowest point is designed by a specific mathematical model.

[0067] The surface structures of the two free-form surfaces are the same, and the highest point of one free-form surface is symmetrical to the highest point of the other free-form surface with respect to the section 3 of the lens, such as Figure 2b As shown, the lowest point of one free-form surface is symmetrical to the lowest point of the other free-form surface with respect to the section 3 of the lens.

[0068]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com