Brushless doubly-fed machine

A technology of doubly-fed motor and armature iron core, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as difficulty in meeting high-performance engineering applications, low power factor of brushless doubly-fed motor, torque fluctuation, etc. Achieve the effect of improving the air gap magnetic field distribution, simplifying the processing technology, and improving the operating efficiency of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

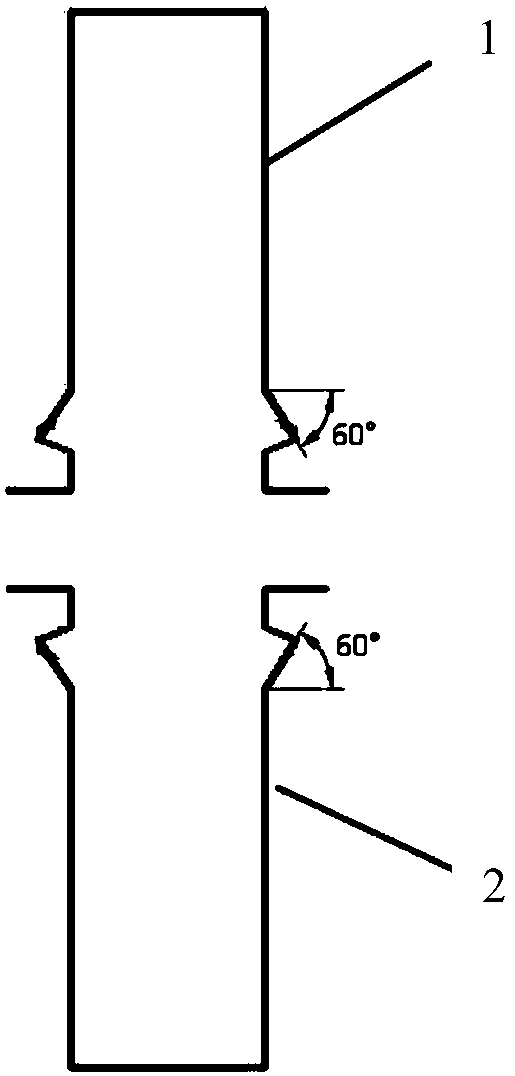

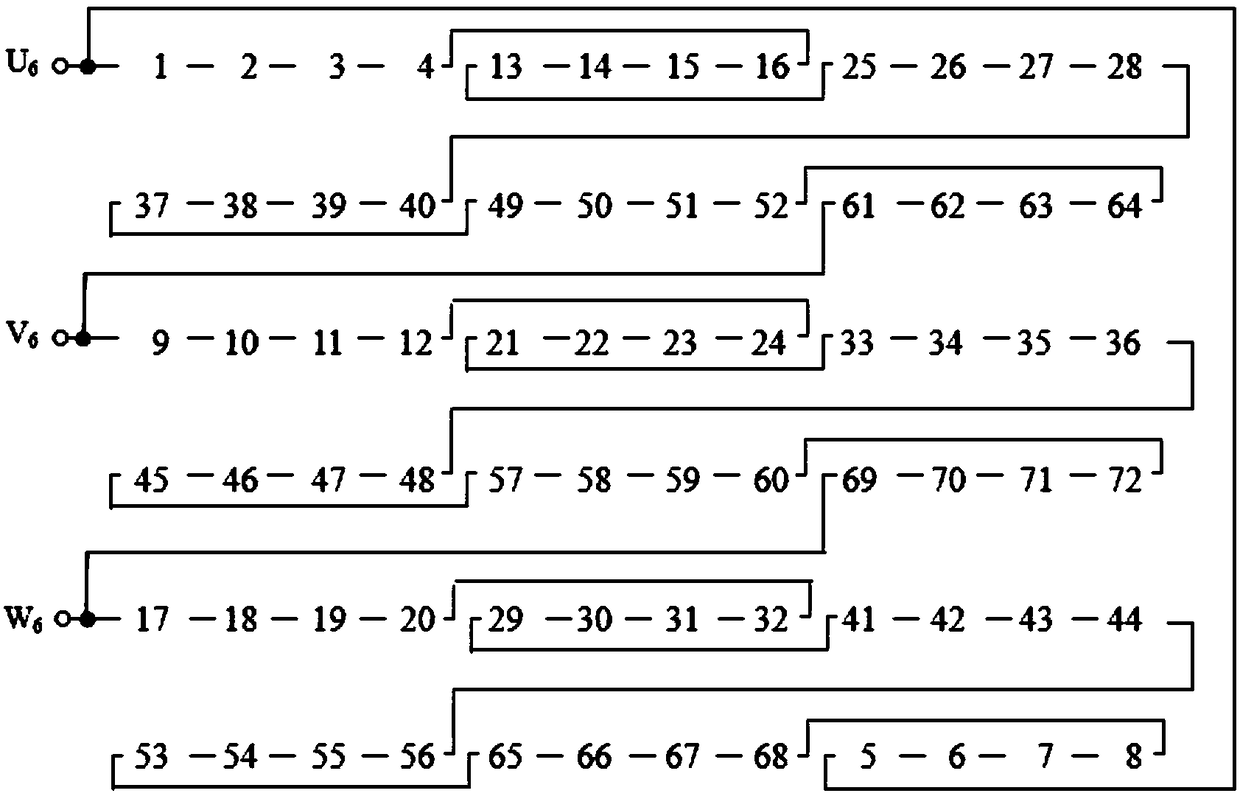

[0038] Stator armature core punching slot 1 is the stator armature core punching rectangular slot, the number of stator armature core punching rectangular slots is 72, rotor armature core punching slot 2 is the rotor armature core punching slot There are 96 rectangular slots in the rotor armature core. The power winding adopts 72 slots, 2 poles and 3 phases, and the control winding adopts 72 slots, 6 poles and 3 phases.

[0039] In order to further optimize the above technical solution, the number of turns of each coil of the power winding is 22, the coil span Y=29, and a total of 36 coils.

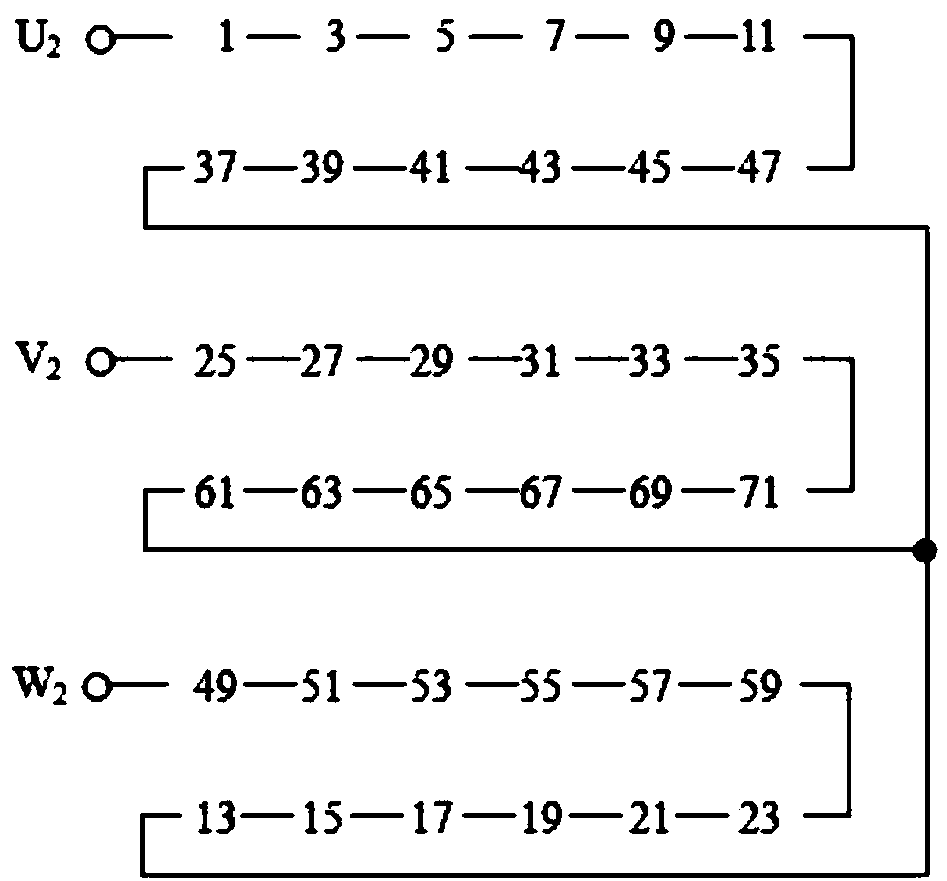

[0040] In order to further optimize the above technical solution, the number of turns of each coil of the control winding is 3, the coil span Y=10, and a total of 72 coils.

[0041] In order to further optimize the above technical solution, the number of turns of the rotor winding coil is 1, and a variable-span wiring method is adopted, with a total of 76 coils.

Embodiment approach

[0042] Here, a brushless double-fed motor with a rated power of 560Kw, a rated speed of 750r / min, a rated power frequency of 50Hz, and a speed range of 750r / min-1000r / min is used to introduce the specific implementation method. The implementation method includes the following steps:

[0043] Step 1: Calculation of stator winding pole pairs. Due to the number of pole pairs of the power winding p p and control winding pole pairs p c The size of the motor determines the speed range of the motor. Combined with the rated speed requirements of the motor, the number of pole pairs can be determined as: p r =p p +p c =4.

[0044] Step 2: Determine the number of pole pairs of control winding and power winding. In order to eliminate the electromagnetic interaction between the two stator windings, the number of pole pairs should satisfy p p ≠p c . Considering that when p p and p c The larger the difference, the more noise and vibration can be reduced and in order to generate a ...

Embodiment 2

[0055] Stator armature core punching slot 1 is the stator armature core punching rectangular slot, the number of stator armature core punching rectangular slots is 72, rotor armature core punching slot 2 is the rotor armature core punching slot There are 56 rectangular slots in the rotor armature core. The power winding adopts 72 slots, 2 poles and 3 phases, and the control winding adopts 72 slots, 6 poles and 3 phases.

[0056] In order to further optimize the above technical solution, the number of turns of each coil of the power winding is 34, the coil span Y=29, and there are 36 coils in total.

[0057] In order to further optimize the above technical solution, the number of turns of each coil of the control winding is 3, the coil span Y=10, and a total of 72 coils.

[0058] In order to further optimize the above-mentioned technical solution, the number of turns of each coil of the rotor winding is 1, and a variable-span wiring method is adopted, with a total of 64 coils. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com