A straightening mechanism in a steel bar straightening machine

A technology of straightening machine and steel bar is applied in the field of construction equipment of construction engineering, which can solve the problems of inability to straighten the steel bar, cannot obtain high straightness, and it is difficult to ensure the safety and accuracy of construction projects, so as to improve the straightness, reduce bending, The effect of ensuring safety and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

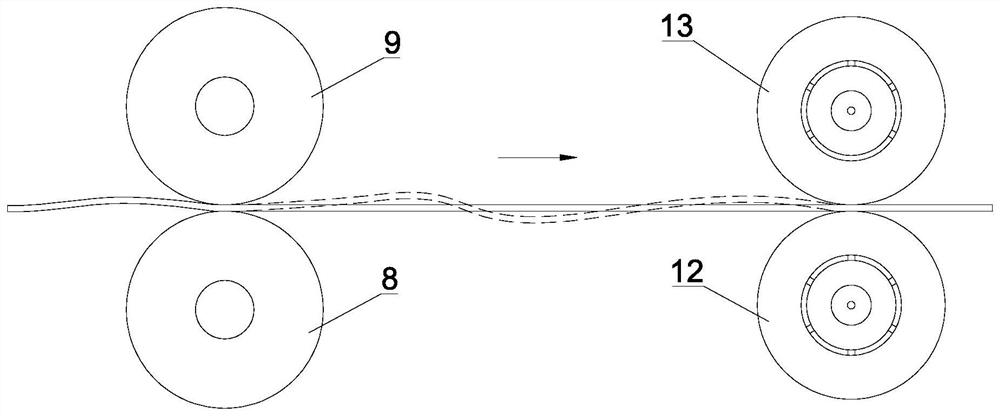

[0038] see Figure 1-3 with Figure 6-8 , the straightening mechanism in the steel bar straightening machine in the present embodiment comprises a chassis 1 and a traction unit and a straightening unit arranged on the chassis 1; wherein, the traction unit comprises two traction wheels and a driving The traction power mechanism that the traction wheel rotates; the straightening unit includes two straightening wheels that are arranged up and down oppositely and a straightening power mechanism that drives the straightening wheel to rotate. The mechanism is rotatably connected; along the conveying direction of the steel bar, the straightening wheel is located in front of the traction wheel.

[0039] In the work of steel bar straightening, the straightening power mechanism drives the linear speed of the straightening wheel to rotate greater than the linear speed of the traction power mechanism to drive the traction wheel to rotate; when the steel bar is straightened, the straighte...

Embodiment 2

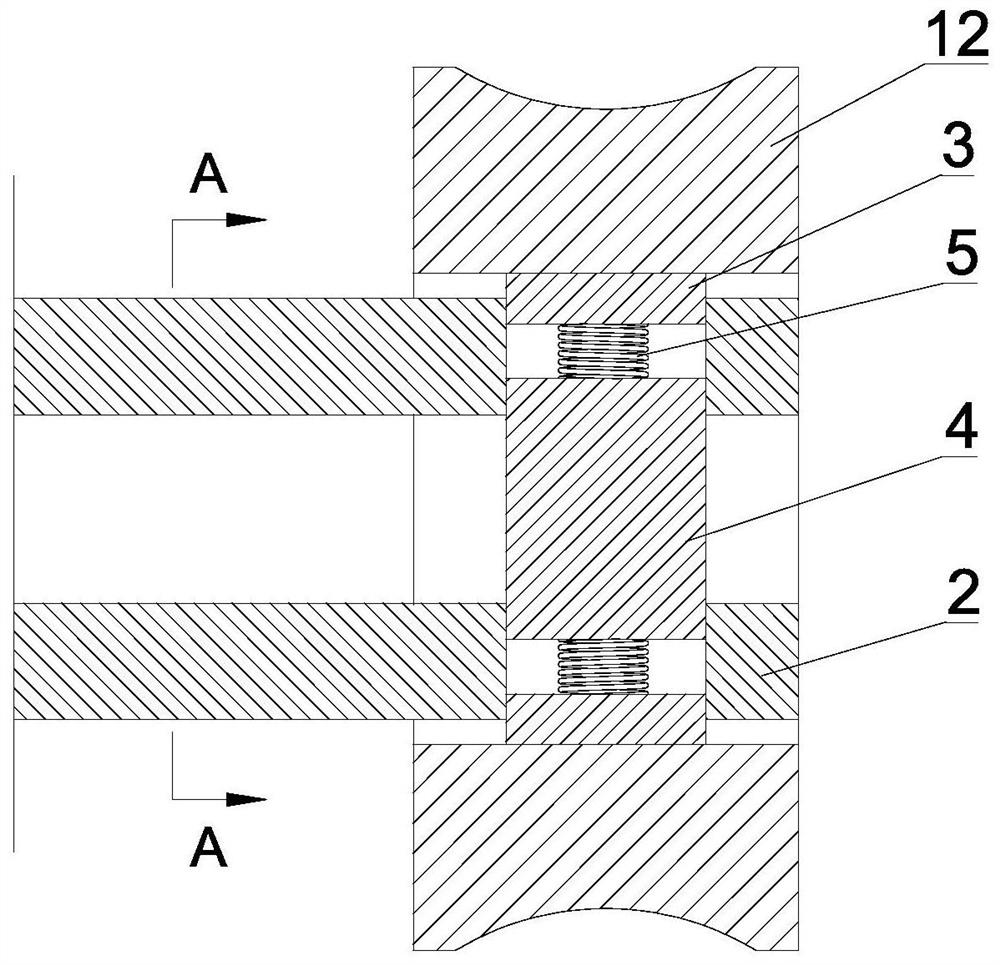

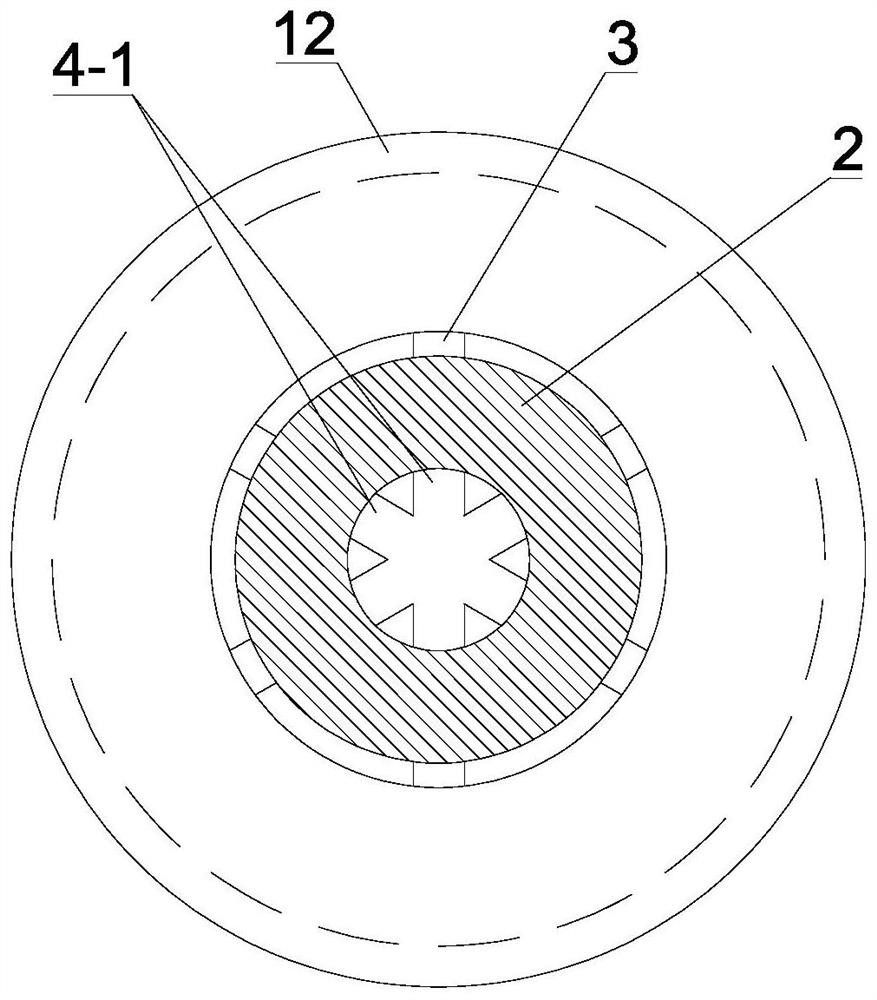

[0052] see Figure 4-5 , and the difference from Embodiment 1 is that the slidable connection structure includes a rotating shaft 2 connected to the straightening power mechanism and a first rotating member 3, a second rotating member 4, an adjusting rod 6, a compression Spring 5; wherein, the rotating shaft 2 is a hollow structure, and one end near the straightening wheel is provided with a plurality of mounting holes evenly distributed along the circumferential direction; the number of the first rotating member 3 and the second rotating member 4 Equal to the number of mounting holes, the upper end of the first rotating member 3 is on the inner hole wall of the straightening wheel, and the lower end extends into the mounting hole; the adjusting rod 6 is located in the inner hole of the rotating shaft 2, and is the same shaft, one end is the adjusting end of the truncated circular structure, and the other end is the rotating end of the cylindrical structure; the adjusting end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com