Quick cooling mechanism of plastic kneading machine

A kneader and plastic technology, which is applied in the field of rapid cooling mechanism of plastic kneader, can solve the problems of temperature rise, inability to effectively dissipate, and affect the normal operation of the kneader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

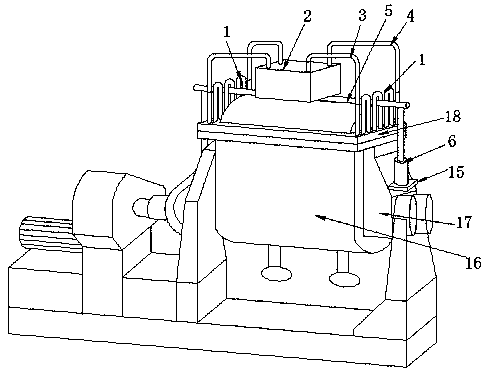

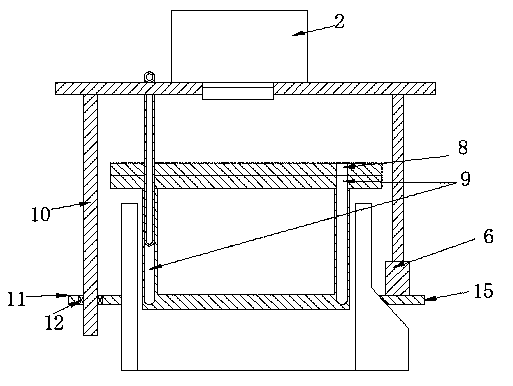

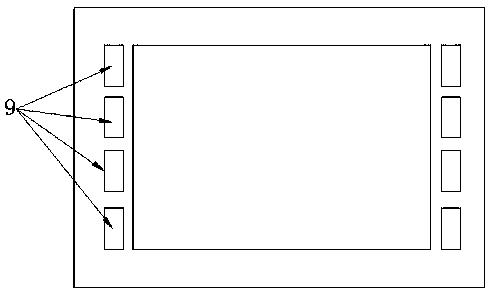

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] see as Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a group of symmetrically arranged corrugated cooling pipes 1, a cooling liquid tank 2, a cooling liquid outlet pipe 3, a cooling liquid return pipe 4, a support frame 5, a lifting motor 6, Submersible pump 7, top cover perforation 8, kneader body cooling tank 9; guide rod 10, linear bearing mounting plate 11, linear bearing 12; described lifting motor 6 is fixed on the support block 17 of the side wall of the kneader body 16, The upper end of the output shaft of the lifting motor 6 is welded with one end of the support frame 5, the other end of the support frame 5 is welded with the upper end of the guide rod 10, and the lower end of the guide rod 10 is connected with the linear bearing 12 arranged in the linear bearing mounting plate 11. The linear be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com