Silver paste filling device

A filling device, silver paste technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problem of feeding pipe blockage and other problems, and achieve the effect of easy replacement, speeding up work efficiency, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

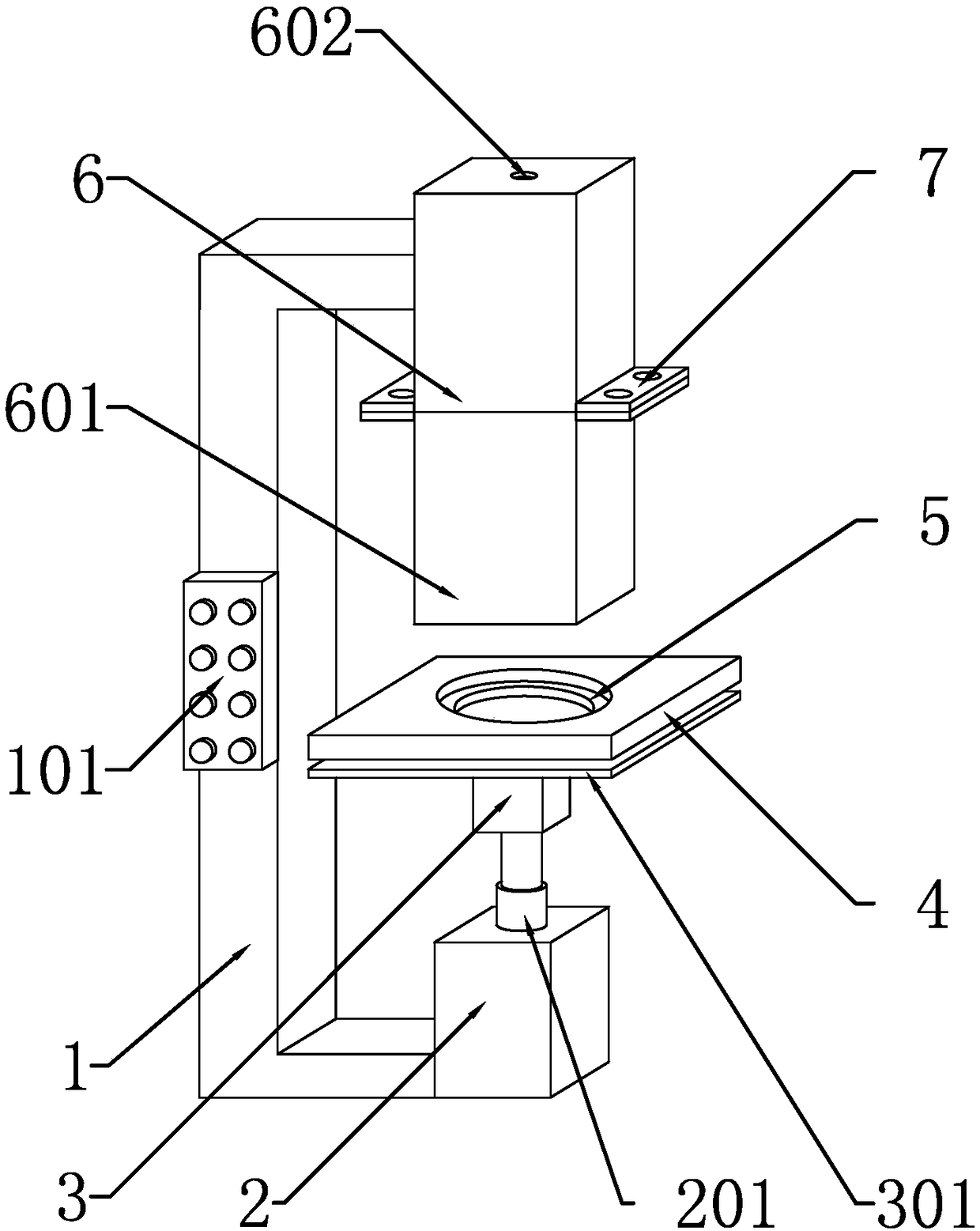

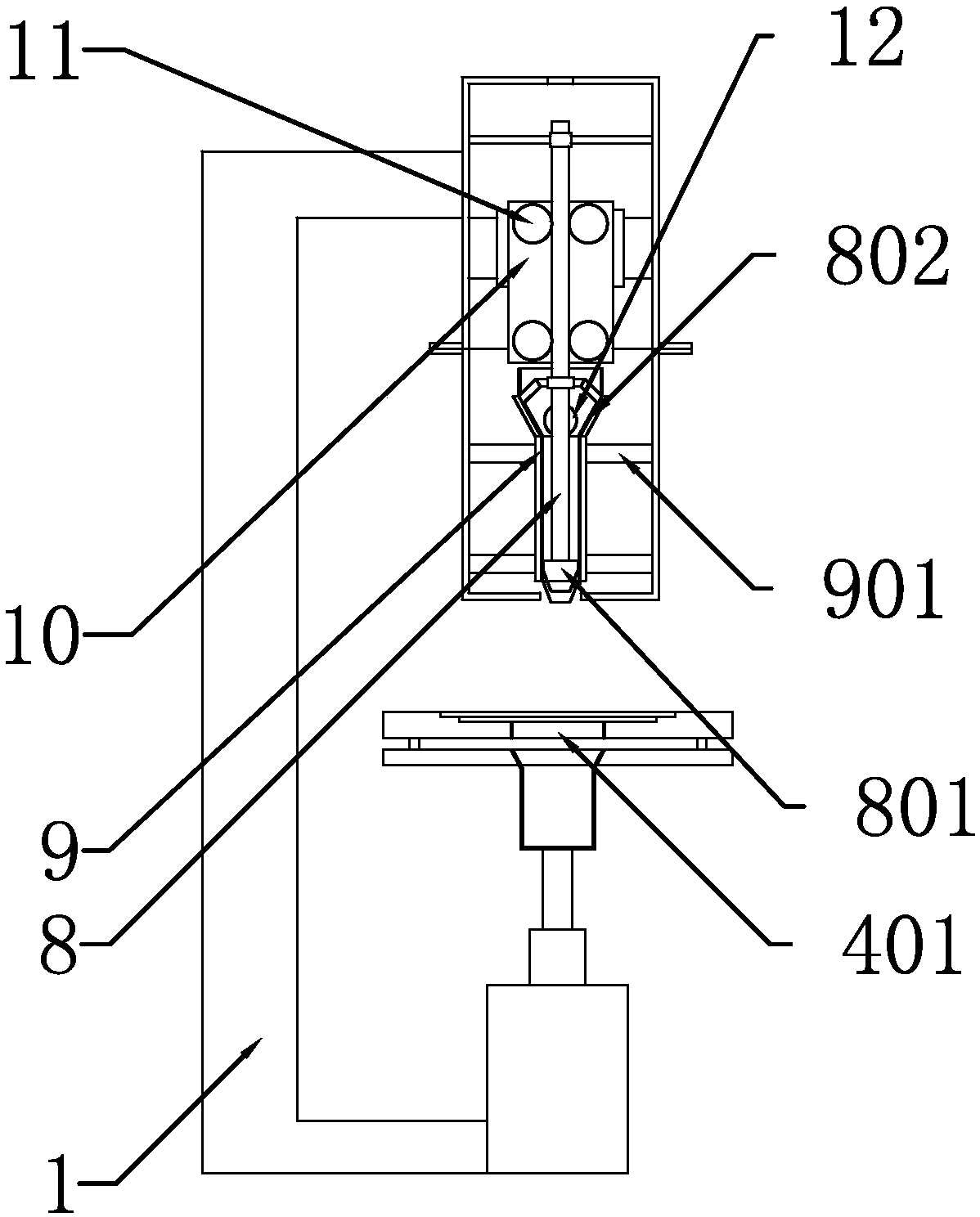

[0023] like Figure 1-2 As shown, in the embodiment of the present invention, a silver paste filling device includes a fixed frame 1, a control button 101, a bottom hydraulic cylinder 2, a hydraulic rod 201, a collection box 3, a bottom pallet 301, a weighing platform 4, a bottom Empty slot 401, placement slot 5, feeder protection box 6, feeder protection cover 601, top through hole 602, side fixing plate 7, sealing rod 8, scraping protrusion 801, feeding tube 802, heating jacket 9, fixing frame 901 , the inner protection box 10, the rotating motor 11 and the feeding hole 12, the control button 101 is located in the left middle section of the fixed frame 1, and the control button 101 is fixedly connected with the fixed fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com