Double-sided twill doffer card clothing

A double-sided twill and twill weave technology, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of falling net, fiber straightness, poor parallelism and separation, and returning flowers, etc., to improve transfer Efficiency, avoiding air turbulence, and good effect of dredging air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

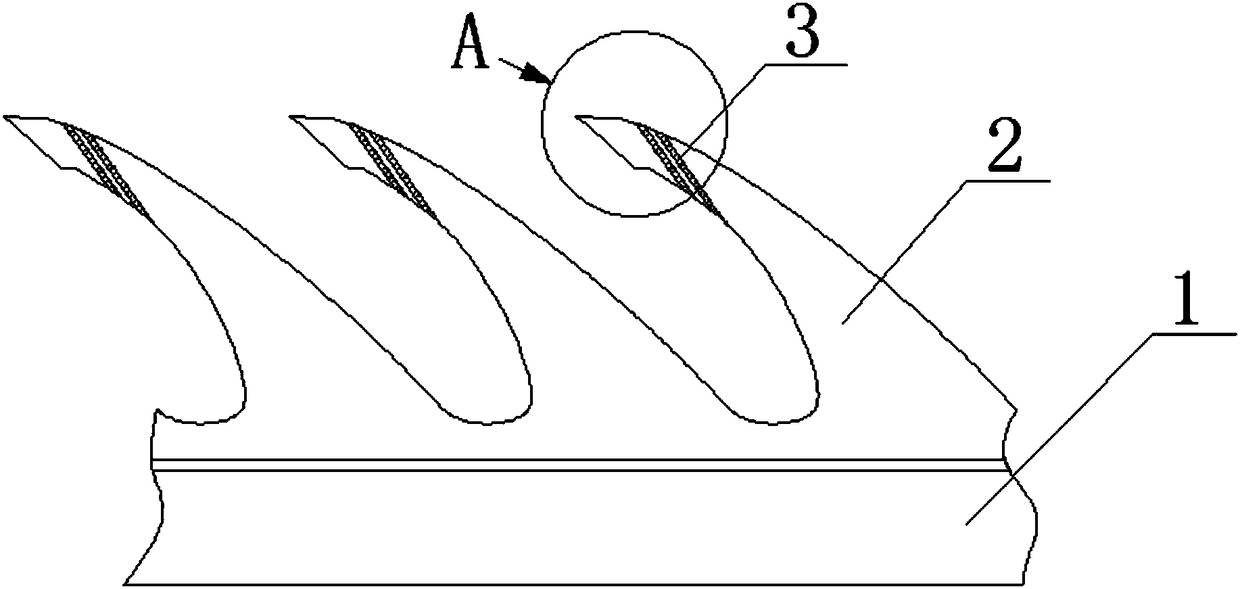

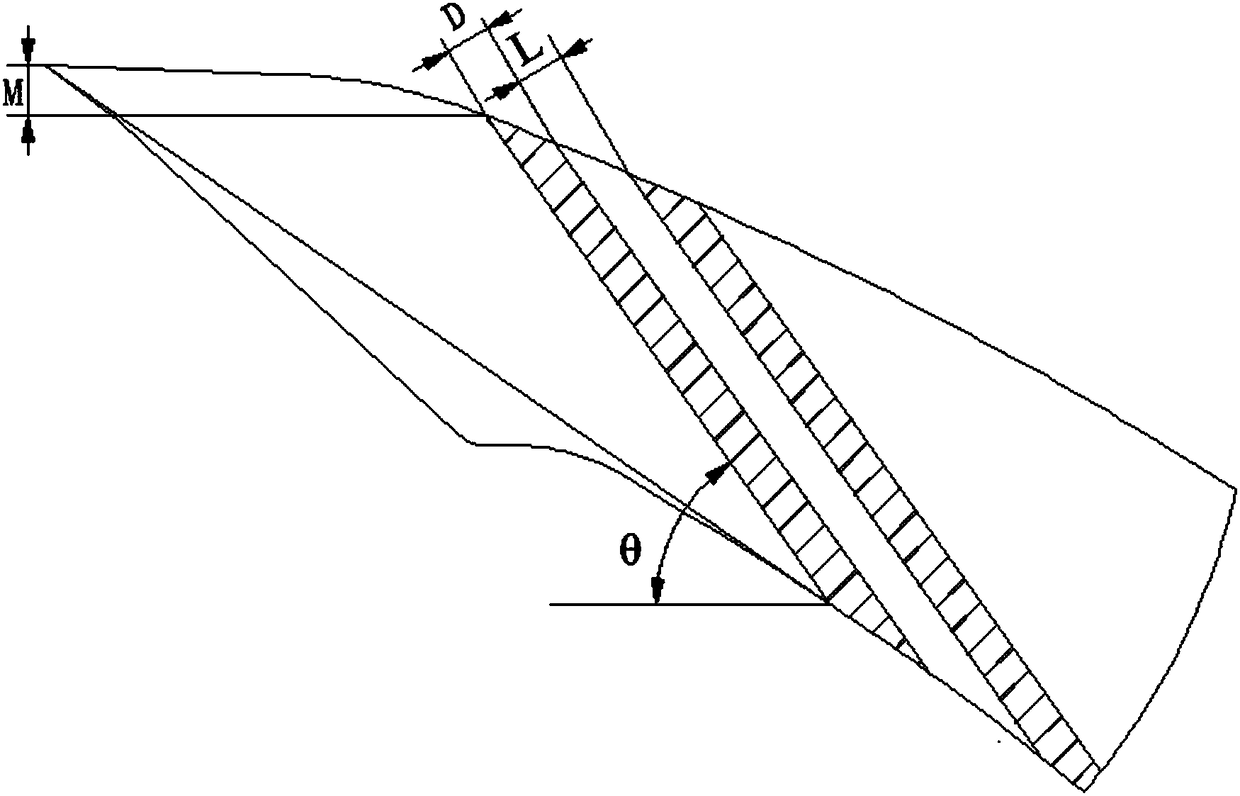

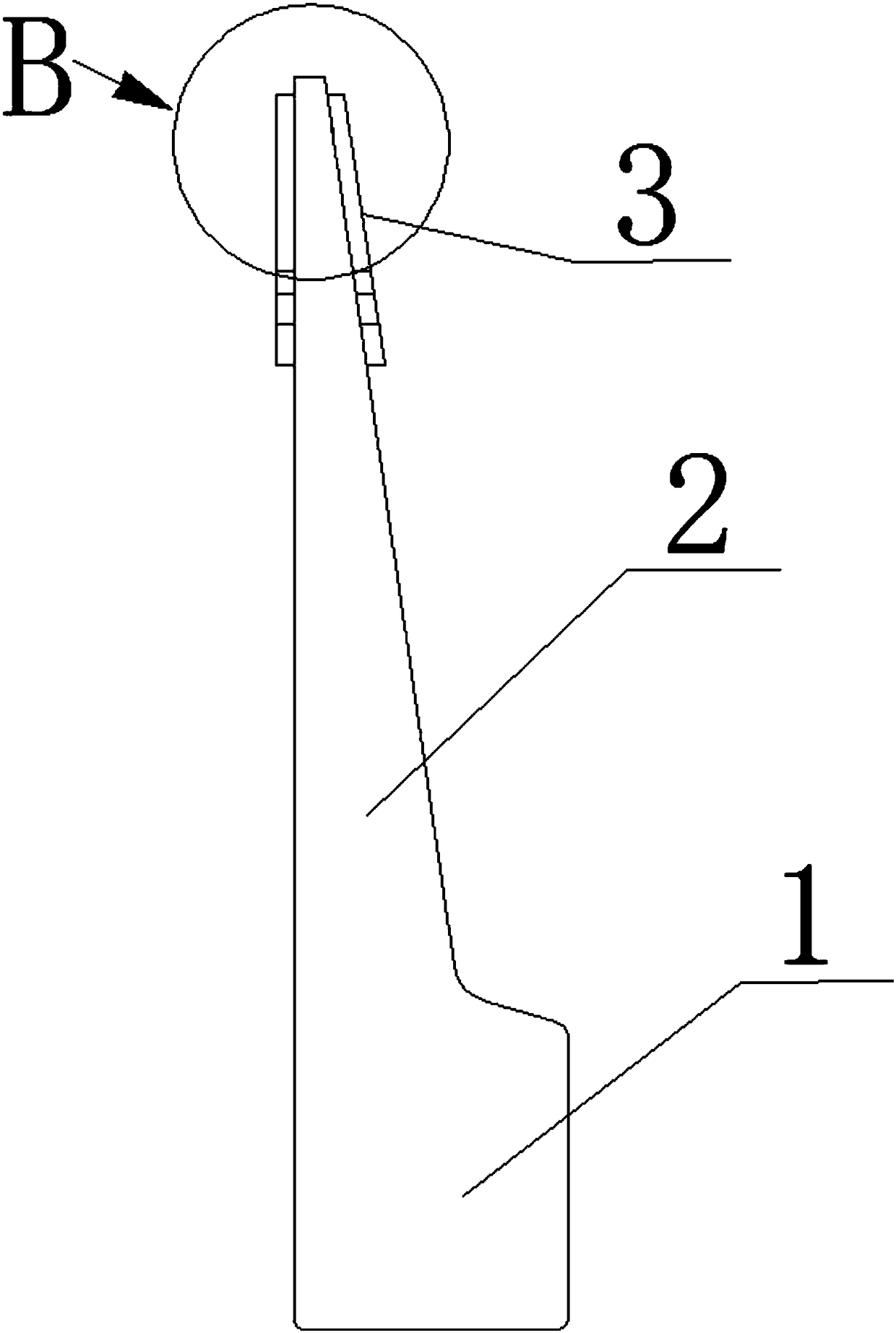

[0014] Such as figure 1 As shown, the double-sided twill doffer card clothing involved in this embodiment includes a base 1 and needle teeth 2 evenly distributed on the base 1. At least two raised twill 3 and twill 3 are provided on both sides of the needle 2 The included angle with the bottom surface of the base θ=45-55°.

[0015] Further, the thickness of the twill weave in this embodiment is D=0.02mm-0.08mm, the height of the twill is H=0.02mm-0.06mm, the distance between two adjacent twills is L=0.02mm-0.06mm, the highest point of the twill The distance from the top surface of the needle tooth is M=0.03mm-0.05mm.

[0016] Preferably, the thickness of the twill weave in this embodiment is D=0.05mm, the height of the twill is H=0.04mm, the distance between two adjacent twills is L=0.04mm, and the distance between the highest point of the twill and the top surface of the pin tooth is M= 0.04mm, the number of twill lines is 2-3.

[0017] Further, the needle tip shape of the needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com