Single-sided twill doffer card clothing

A twill and card clothing technology, applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of falling net, poor fiber straightness, parallelism and separation, and re-embroidery, and improve the transfer rate. , The effect of improving the final yarn index and facilitating the processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

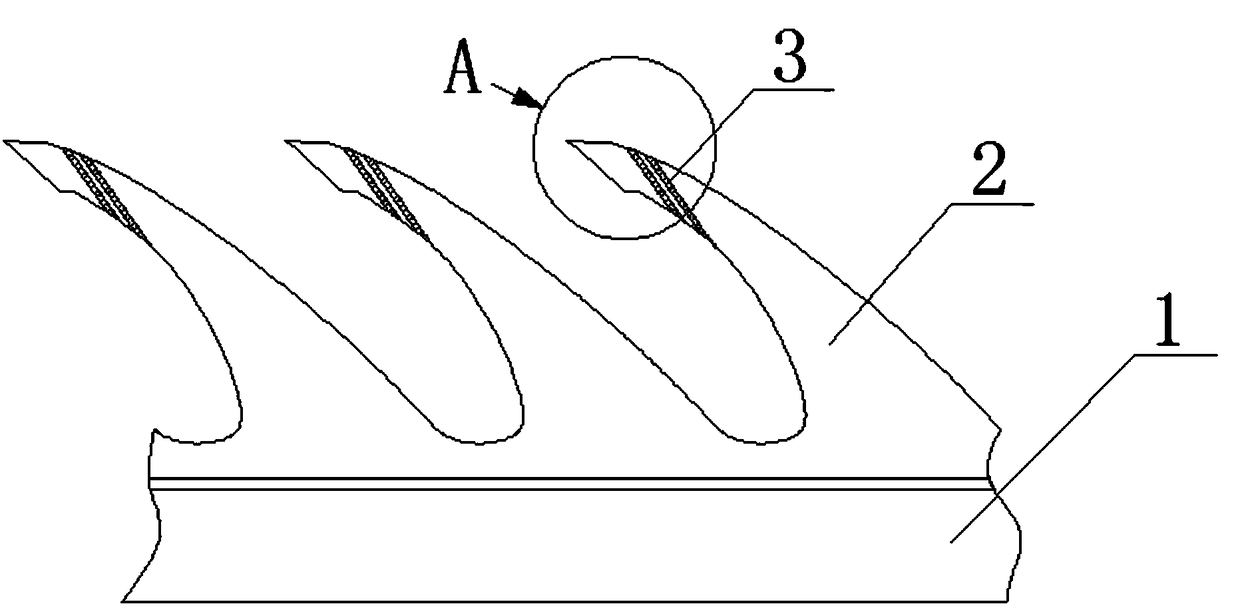

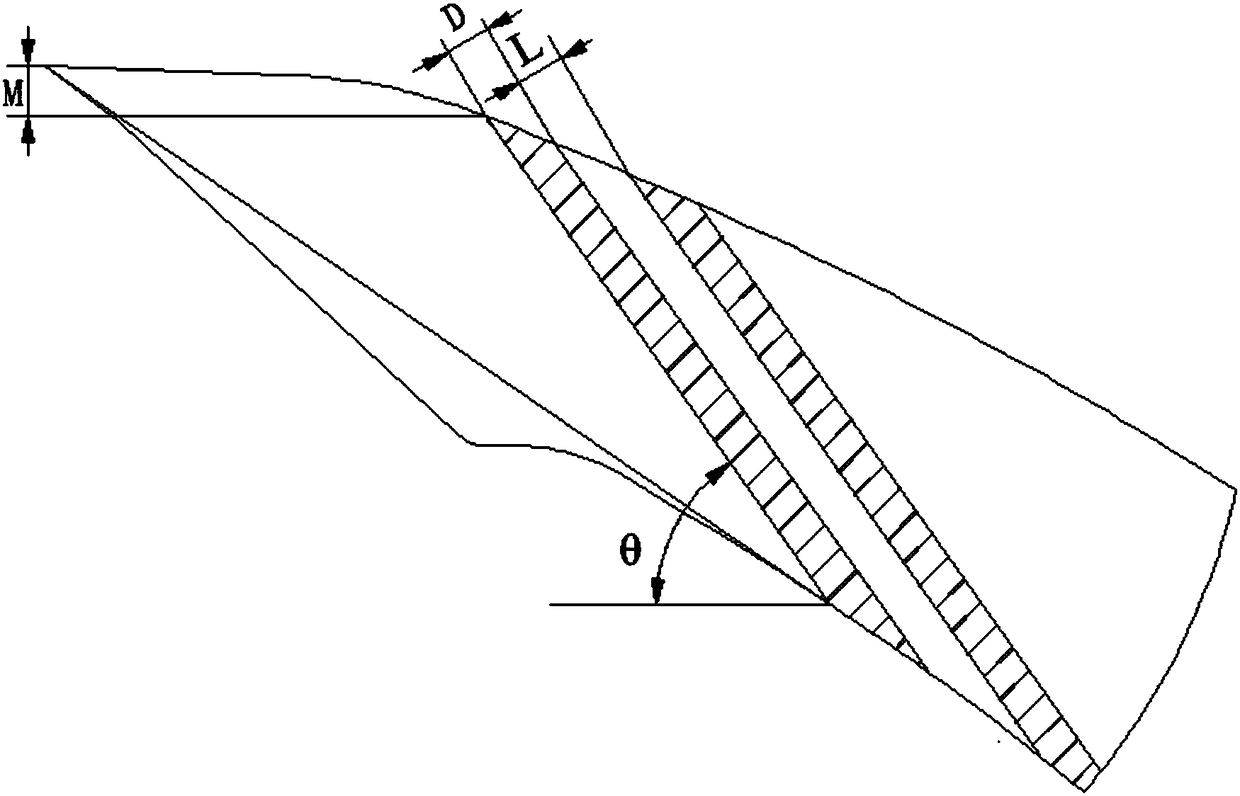

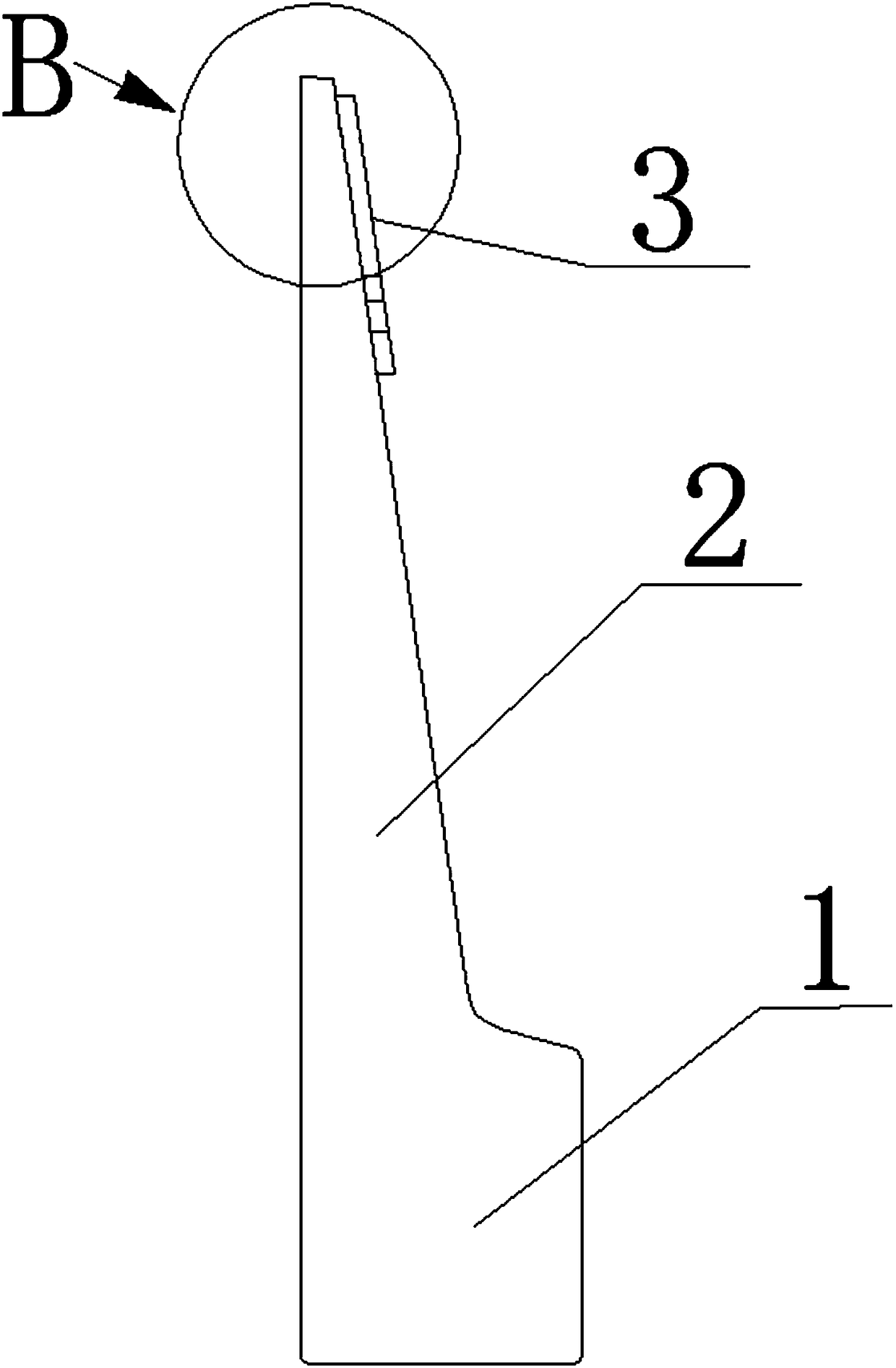

[0014] Such as figure 1 As shown, the single-sided twill doffer clothing involved in this embodiment includes a base 1 and needle teeth 2 evenly distributed on the base 1. At least two raised or recessed twill patterns 3 are provided on the bevel of the needle teeth 2 3 The angle θ between the bottom surface of the base and the base is 45-55°

[0015] Further, the thickness of the twill weave in this embodiment is D=0.02mm-0.08mm, the height of the twill is H=0.02mm-0.06mm, the distance between two adjacent twills is L=0.02mm-0.06mm, the highest point of the twill The distance from the top surface of the needle tooth is M=0.03mm-0.05mm.

[0016] Preferably, the thickness of the twill weave in this embodiment is D=0.05mm, the height of the twill is H=0.04mm, the distance between two adjacent twills is L=0.04mm, and the distance between the highest point of the twill and the top surface of the pin tooth is M= 0.04mm, the number of twill lines is 2-3.

[0017] Further, the needle tip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com