Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, vehicle parts, etc., can solve problems such as decreased production efficiency, and achieve the effect of improving followability and improving recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

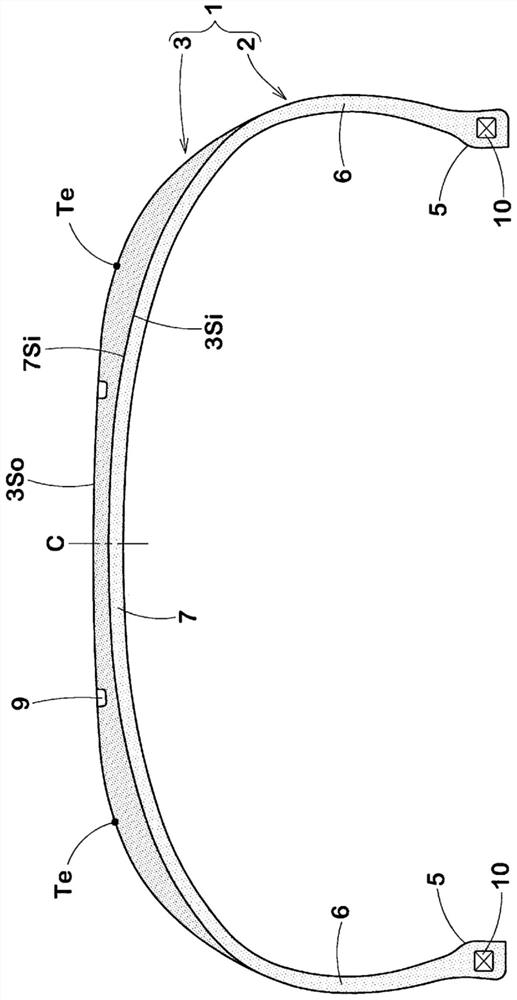

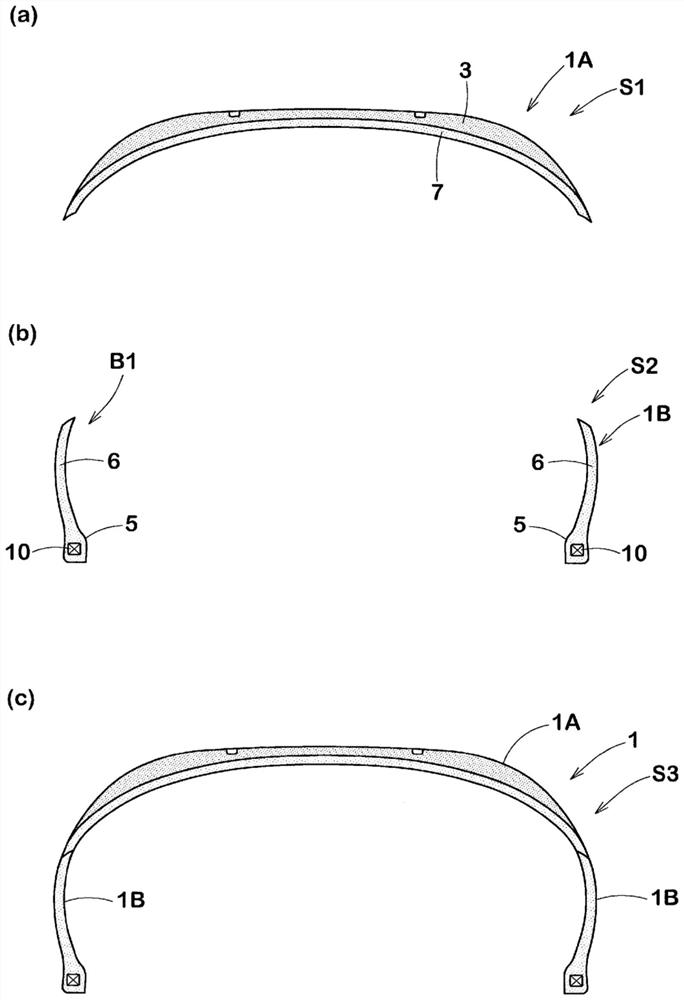

[0081] In order to confirm the effect of the present invention, according to the specifications of Table 1, a figure 1 Passenger car tires (195 / 65R15) of the construction shown.

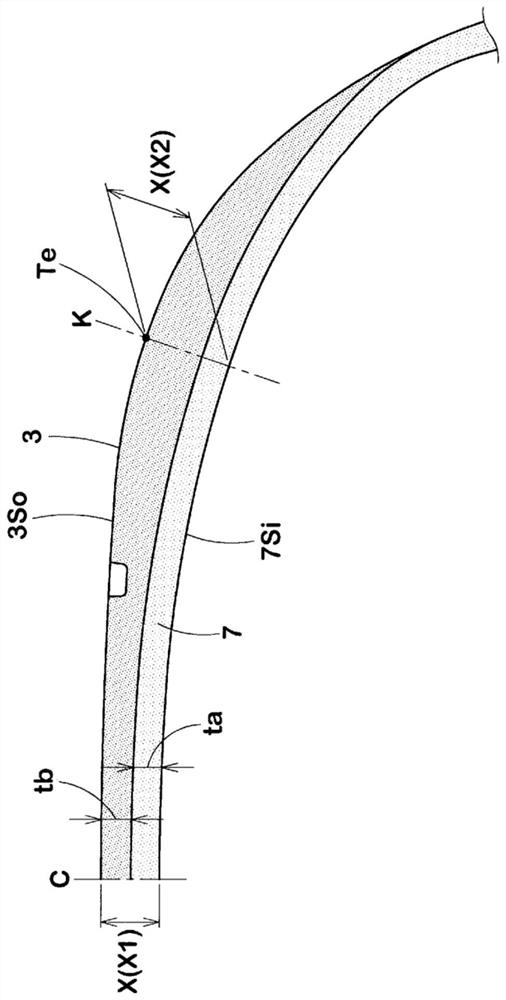

[0082] In the comparative example and the embodiment, only the resin material used in the tire frame member 2, the resin material used in the tread ground contact member 3, and the tread thickness ratio X2 / X1 are different. In addition, the ratio X2 / X1 is adjusted by varying the thickness tb of the tread contact member 3 .

[0083] For the comparative example and the embodiment, by computer simulation, calculate the ground contact area of the tire when it is perpendicular to the road surface under the conditions of normal rim (15×6JJ), normal internal pressure (230kPa) and normal load (3.43kN), and compare them with each other .

[0084]

[0085] is an index of grip, and is represented by an index of 10 in Comparative Example 1. The larger the value, the larger the ground contact area and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com