Full-multifilament double-strand sewing thread with tensile expansion property and manufacturing method thereof

A technology of stretching expansion and manufacturing method, which is applied in the field of sewing thread, can solve the problems that have not been actually produced and cannot be mass-produced, and achieve the effect of easy production and application, and stable twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

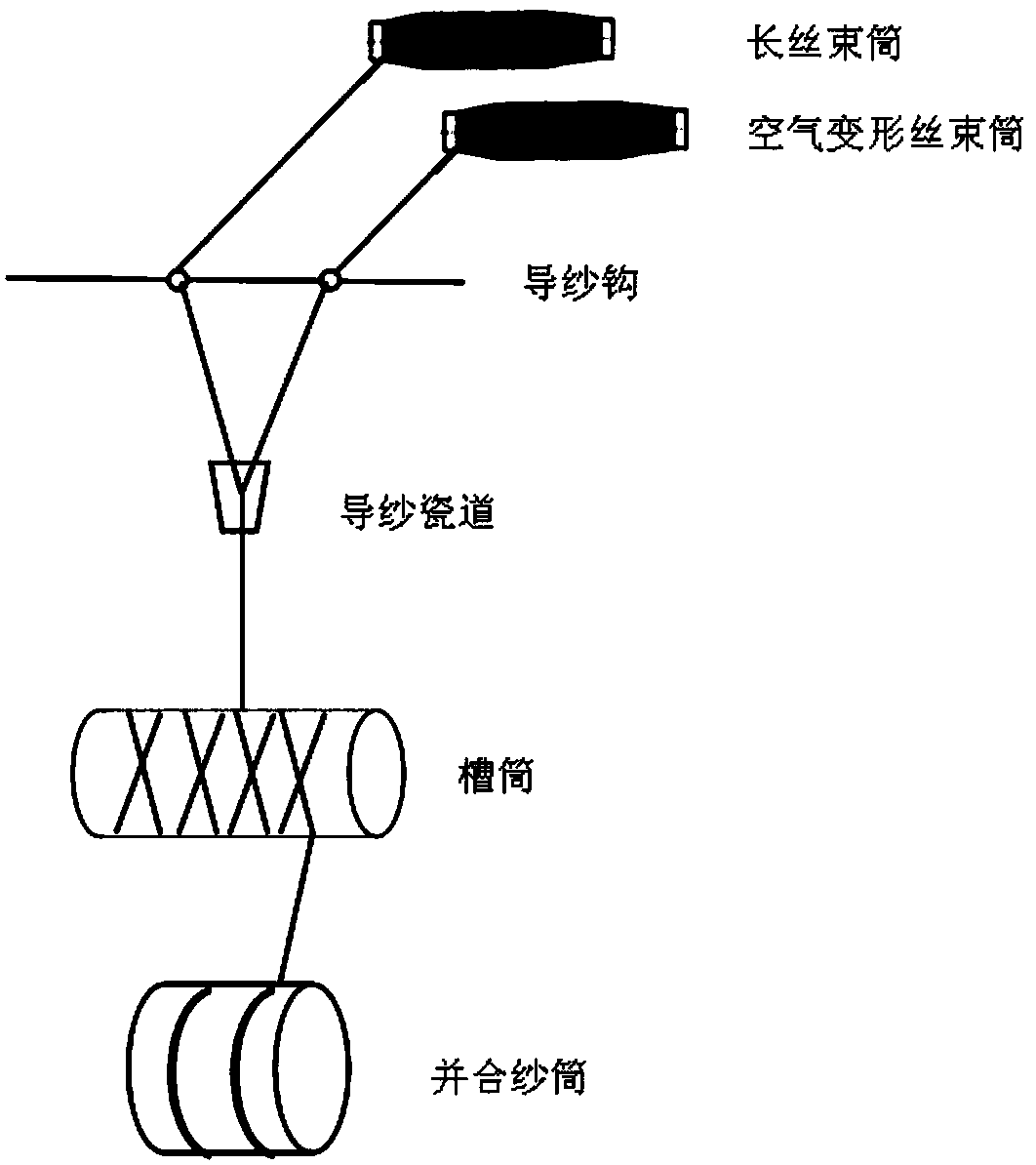

Image

Examples

Embodiment 1

[0047] Production of filament bundles: First, the selected FDY filaments are bundled and paralleled to obtain untwisted multifilament bundles, and then the untwisted multifilament bundles are passed through the twisting process to increase the twist of 5T / 10cm, so as to obtain high rigidity twist Tow, and then high rigidity twisted tow through the winding process to obtain filament bundle; the breaking strength of the FDY filament is 5.2 cN / dtex.

[0048] Production of air-textured tow: Firstly, the selected POY filaments are bundled and combined to obtain untwisted multifilament bundles, and then the untwisted multifilament bundles are stretched, deformed, thermally stabilized, shaped, and wound in sequence process, to obtain the initial air-textured tow, and then the initial air-textured tow is passed through the winding process to obtain the air-textured tow; the elongation at break of the POY filament is 30%, and the POY filament undergoes deformation processing The overfe...

Embodiment 2

[0051] Production of filament bundles: First, the selected FDY filaments are bundled and doubled to obtain untwisted multifilament bundles, and then the untwisted multifilament bundles are passed through the twisting process to increase the twist of 30T / 10cm, so as to obtain high rigidity twist Tow, and then high rigidity twisted tow through the winding process to obtain filament bundle; the breaking strength of the FDY filament is 12.0 cN / dtex.

[0052] Production of air-textured tow: Firstly, the selected POY filaments are bundled and combined to obtain untwisted multifilament bundles, and then the untwisted multifilament bundles are stretched, deformed, thermally stabilized, shaped, and wound in sequence process, to obtain the initial air-textured tow, and then the initial air-textured tow is passed through the winding process to obtain the air-textured tow; the elongation at break of the POY filament is 60%, and the POY filament undergoes deformation processing The overfee...

Embodiment 3

[0055] Basic content is the same as embodiment 1, the difference is:

[0056] In the production of filament bundles: the untwisted multifilament bundles are passed through the twisting process to increase the twist of 20T / 10cm; the breaking strength of the FDY filaments is 8 cN / dtex.

[0057] In making air-textured tow: the elongation at break of the POY filament is 45%.

[0058] In the production of full-multifilament double-ply sewing thread: the diameter of the filament bundle is 75% of the diameter of the air-textured tow, and the Poisson's ratio of the full-multifilament double-ply sewing thread is -0.24.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com