Novel bearing box

A bearing box, a new type of technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of affecting the service life of the reducer, prone to oil leakage, inconvenient replacement, etc., to achieve flexible lubrication methods, improve Sealing performance, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific implementation plan

[0018] The invention will be further explained below in conjunction with the drawings.

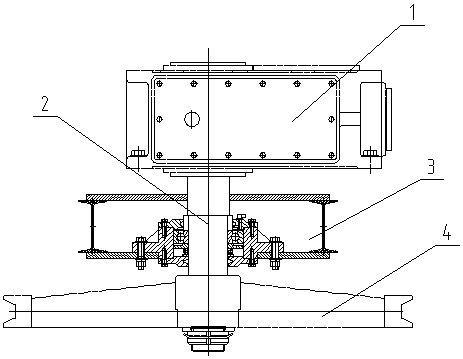

[0019] Such as figure 1 As shown, a new type bearing box 3 and a high-power drive wheel 4 are installed on the output shaft 2 of the reducer 1. The new type bearing box 3 is located between the reducer 1 and the high-power drive wheel 4, and is in a sealed connection with the output shaft 2. The new bearing box 3 can be fixed on the foundation or on the frame.

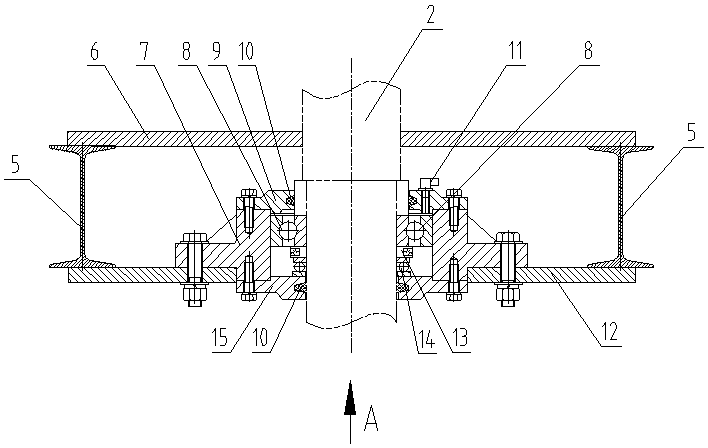

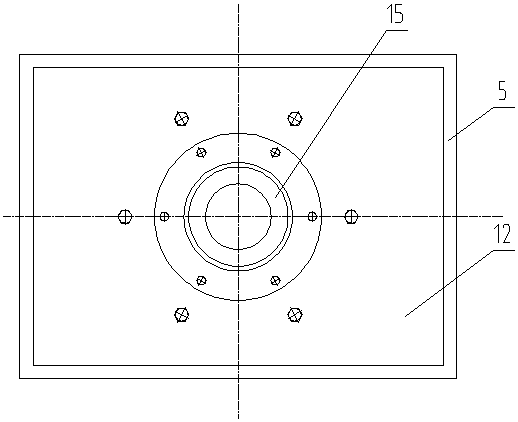

[0020] Such as figure 2 , image 3 As shown, the new bearing box 3 is composed of a box body 5, a front sealing plate 12, and a rear sealing plate 6. The box body 5 is a rectangular frame welded by I-beam. The sealing plate 12 and the rear sealing plate 6 are both made of thick steel plates. This structure is firm and durable, can withstand huge bending moments and large impact forces, and is not prone to deformation. The problem of deformation of the output shaft 2 and oil leakage of the seal wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com