Gas mixer

A mixer and gas technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of limited mixing efficiency, uniform mixing of air flow and gas flow, and short length of gas mixing pipe, so as to increase combustion. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

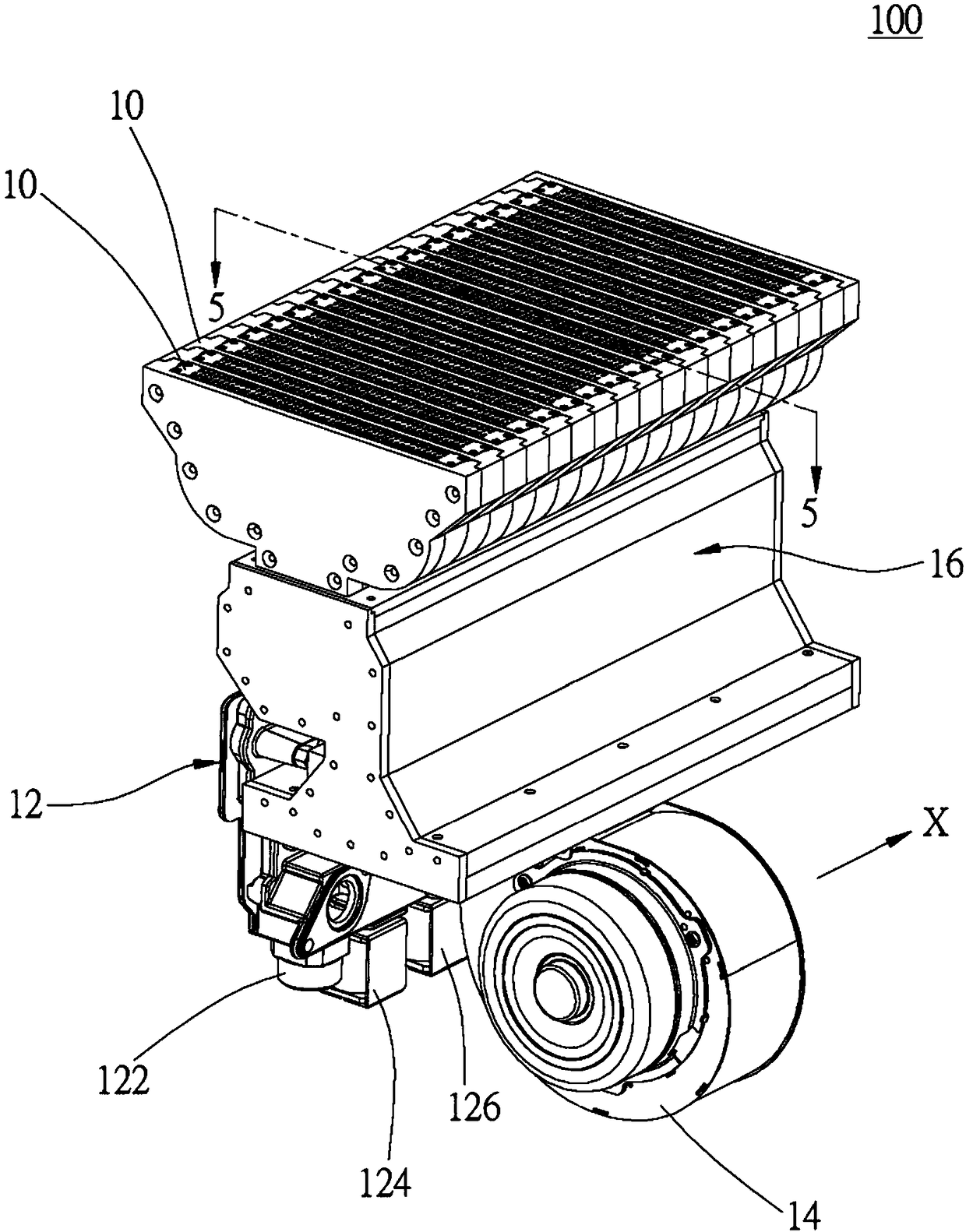

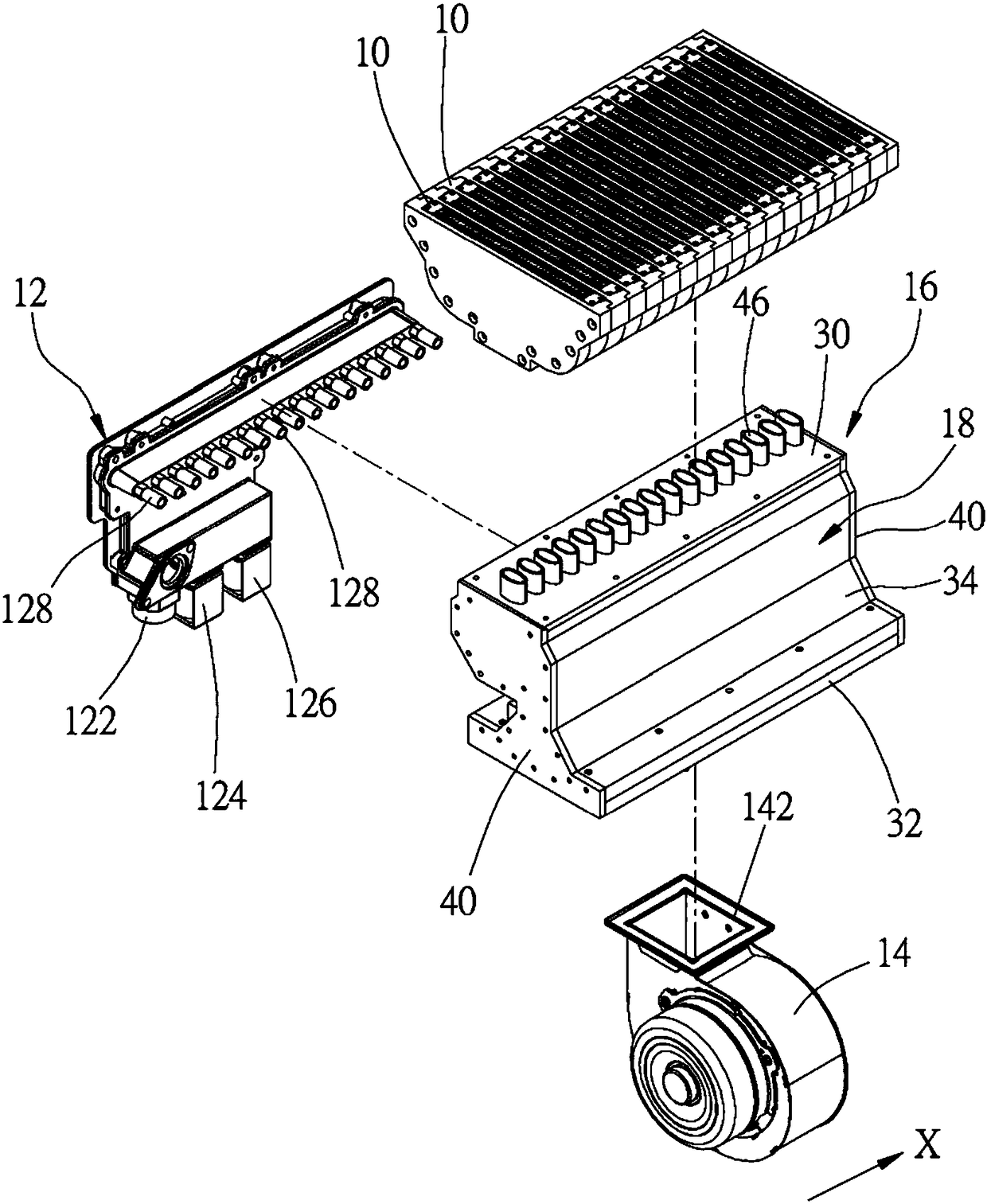

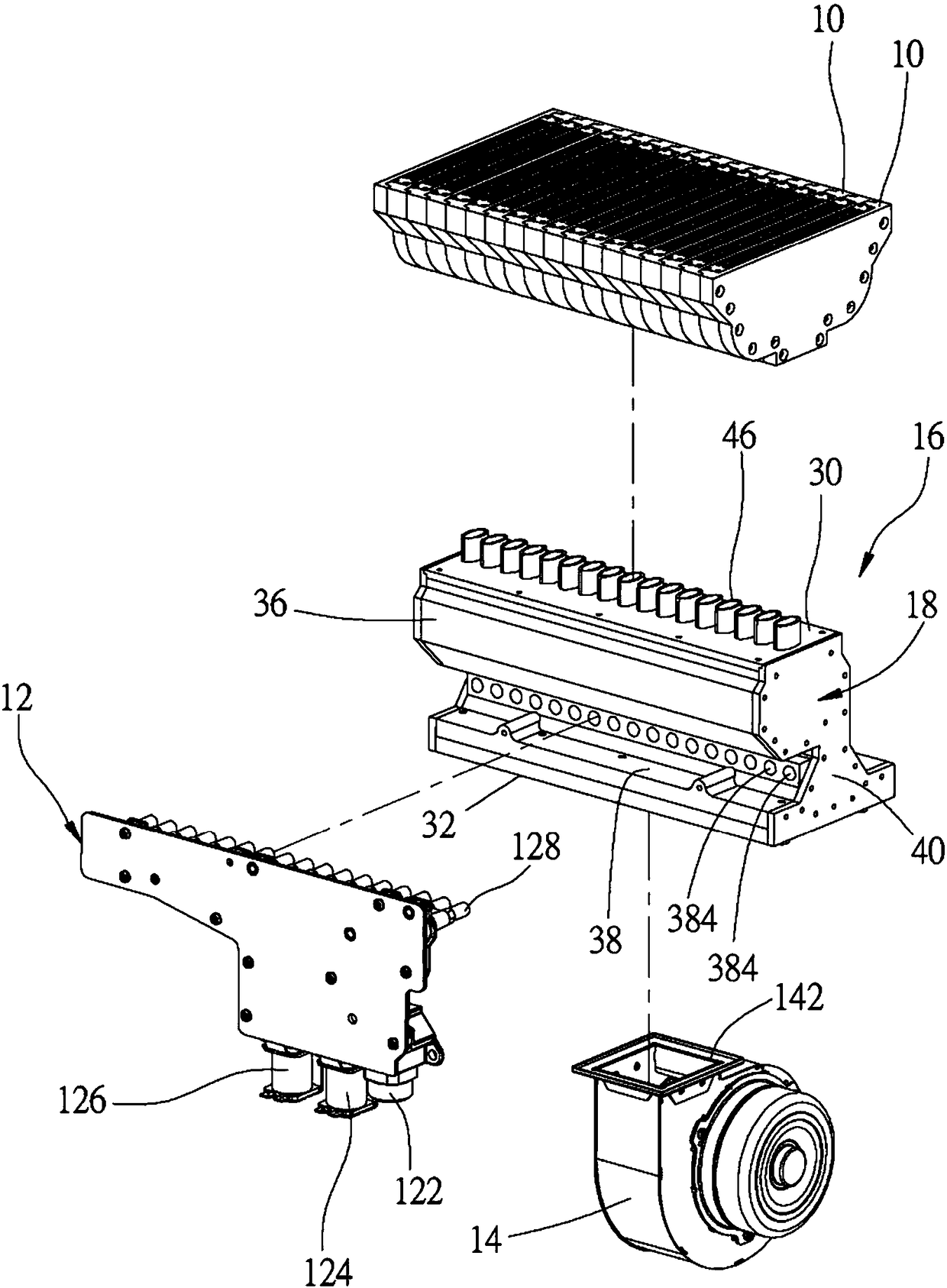

[0049] In order to illustrate the present invention more clearly, a preferred embodiment is now given and described in detail with accompanying drawings as follows. Please refer to Figure 1 to Figure 10 Shown is a gas combustion device 100 with a gas mixer according to the first preferred embodiment of the present invention. The gas combustion device 100 is applied to a water heater as an example, and includes at least one burner 10, a gas intake assembly 12, A blower 14 and the gas mixer 16 of this embodiment.

[0050] The at least one burner 10 is multiple and arranged along a predetermined axis X, and each burner 10 is used to burn gas to generate a flame. The gas intake assembly 12 includes a connection pipe, a solenoid valve 124, a proportional valve 126 and at least one nozzle 128, wherein the connection pipe 122 is connected to a gas source (not shown); the solenoid valve 124 is used to control the opening and closing Or block the gas path; the proportional valve 126...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com