Coal mine underground single prop inspection apparatus

A single pillar and inspection device technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as mine safety production hazards, large inspection errors, and affecting the quality of single pillar laying, and achieve Ensure safe production, ensure support quality, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

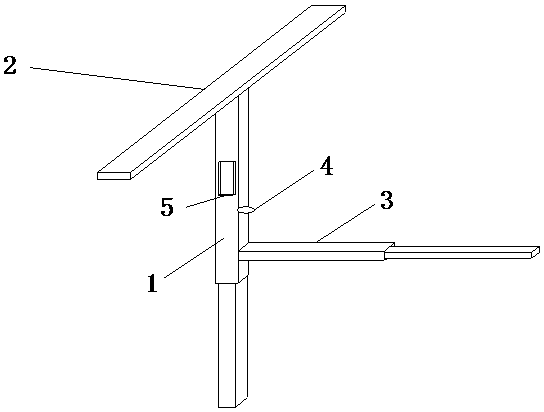

[0012] Such as figure 1 Shown, the present invention comprises vertical chi 1, top chi 2 and cross chi 3, and described top chi 2 is welded on the top of vertical chi 1, and horizontal chi 3 is welded on the side of vertical chi 1, it is characterized in that, in described vertical chi Weld the pressure gauge ring 4 and the data recording card slot 5 on the ruler 1; insert the pressure gauge into the pressure gauge snap ring 4, and the pressure gauge can be removed at any time to check the initial support force and working resistance of the single pillar. The data recording card slot 5 is used to insert the recording card, and the problems of the inspection can be recorded on the recording card at any time during the inspection, so that it is not necessary to hold the record book by hand, which is convenient for operation.

[0013] The top ruler 2 is a fixed length, the hinged roof beam of the coal mining face is generally two specifications of 1m or 1.2m, and the top ruler 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com