Radial pre-grouting method before excavation of the lower steps of tunnels in confined water strata

A bench excavation and pre-grouting technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of difficulty in ensuring grouting effect, increasing water seepage pressure of surrounding rock under the bench, increasing the difficulty of radial grouting, etc. , to improve the support operation environment, ensure the support quality, and improve the effect of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

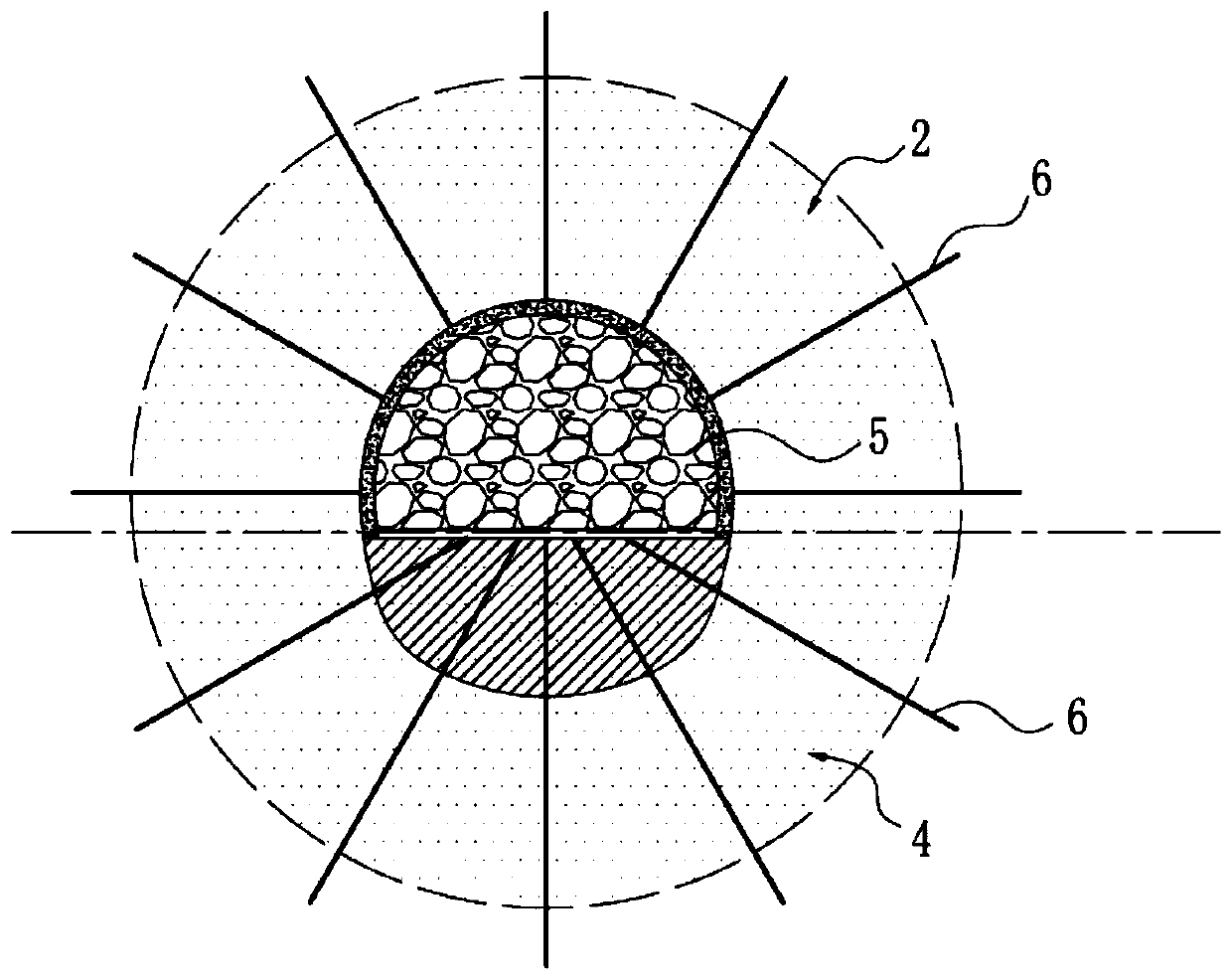

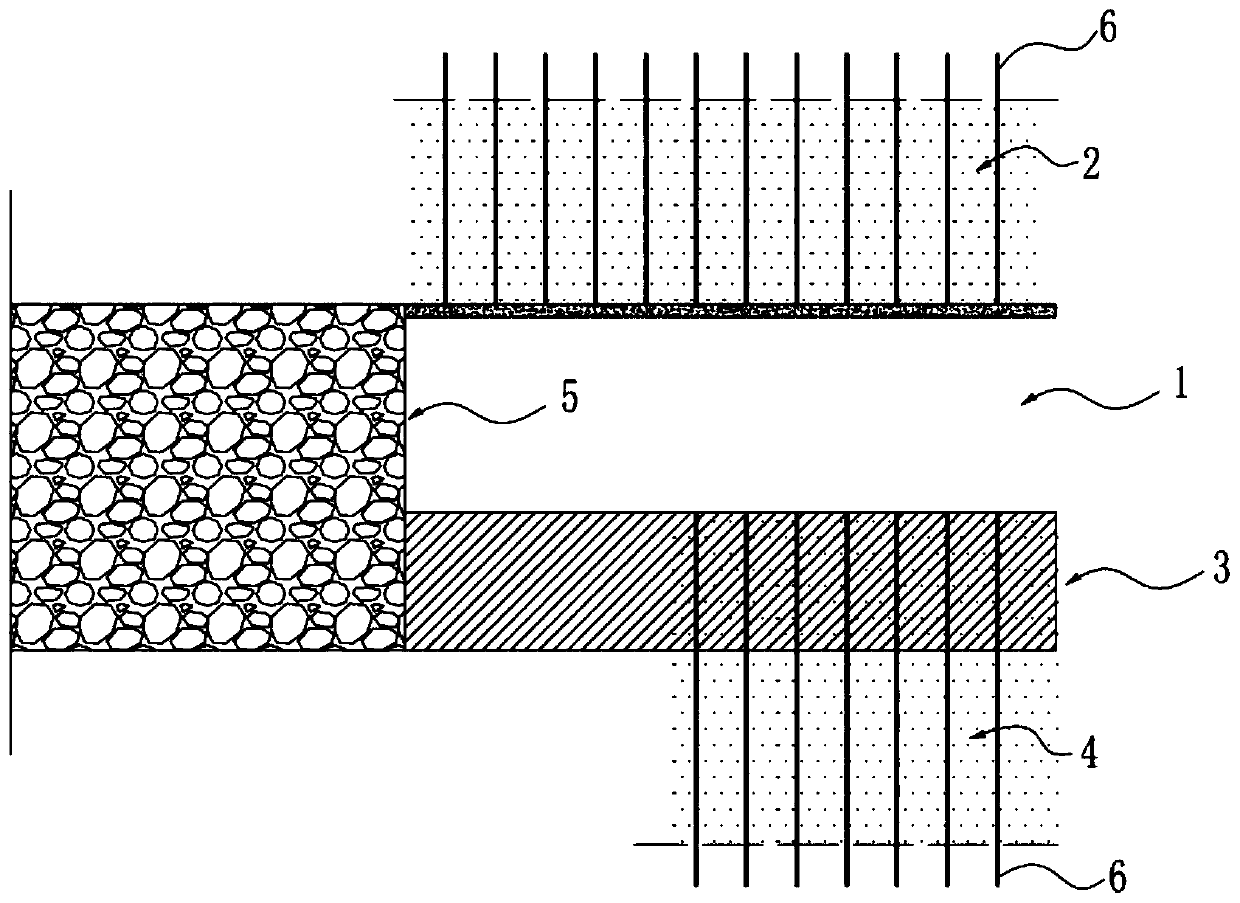

[0027] The radial pre-grouting method before the excavation of the lower step of the tunnel in the confined water stratum includes:

[0028] S1: After the initial support is excavated for the upper step, grouting holes for the upper step are opened, and the leakage point of the initial support is first drained with a grouting pipe, and then the upper step is radially grouted with the grouting pipe to the upper step. The thickness of the consolidation ring is 3m; the arrangement of radial grouting holes on the upper steps and the grouting process are determined according to the location, characteristics, water seepage and water pressure of the leakage point.

[0029] S2: Use the grouting pipe to carry out radial pre-grouting on the surrounding rock of the lower step 2m away from the working face, and the thickness of the consolidation circle of the lower step is 7m. According to the cracks at the seepage point of the upper step and the direction of the structural surface, the s...

Embodiment 2

[0033] The radial pre-grouting method before the excavation of the lower step of the tunnel in the confined water stratum includes:

[0034] S1: After the initial support is excavated for the upper step, grouting holes for the upper step are opened, and the leakage point of the initial support is first drained with a grouting pipe, and then the upper step is radially grouted with the grouting pipe to the upper step. The thickness of the consolidation ring is 4m; the arrangement of radial grouting holes on the upper steps and the grouting process are determined according to the location, characteristics, water seepage and water pressure of the leakage point.

[0035] S2: Use the grouting pipe to perform radial pre-grouting on the surrounding rock of the lower step 5m away from the working face, and the thickness of the consolidation circle of the lower step is 8.5m. According to the cracks at the seepage point of the upper step and the direction of the structural surface, the s...

Embodiment 3

[0038] The radial pre-grouting method before the excavation of the lower step of the tunnel in the confined water stratum includes:

[0039] S1: After the initial support is excavated for the upper step, grouting holes for the upper step are opened, and the leakage point of the initial support is first drained with a grouting pipe, and then the upper step is radially grouted with the grouting pipe to the upper step. The thickness of the consolidation ring is 5m; the layout of radial grouting holes on the upper steps and the grouting process are determined according to the location, characteristics, water seepage and water pressure of the leakage point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com