Tooth-groove type waterproof connecting structure adopting grouting method for vertical joints of assembling type building prefabricated wall boards

A technology of prefabricated wall panels and connecting structures, applied in building components, building structures, buildings, etc., can solve problems such as affecting the quality of prefabricated buildings, easy aging of waterproof materials, and insignificant waterproofing effect, so as to facilitate industrial production, structural Simple, waterproof performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples, but the embodiments of the present invention are not limited thereto, and the scope of protection of the present invention also relates to those skilled in the art who can achieve according to the concept of the present invention. Think of the equivalent technical means.

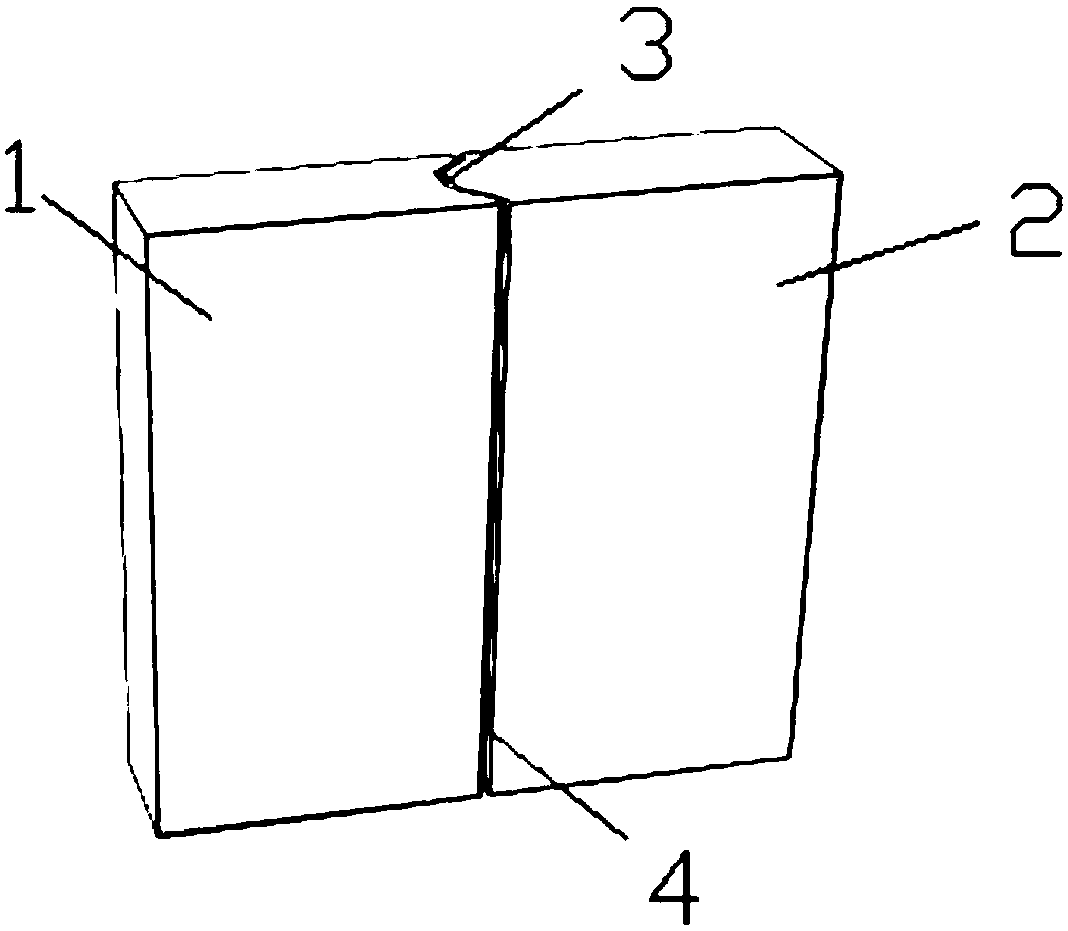

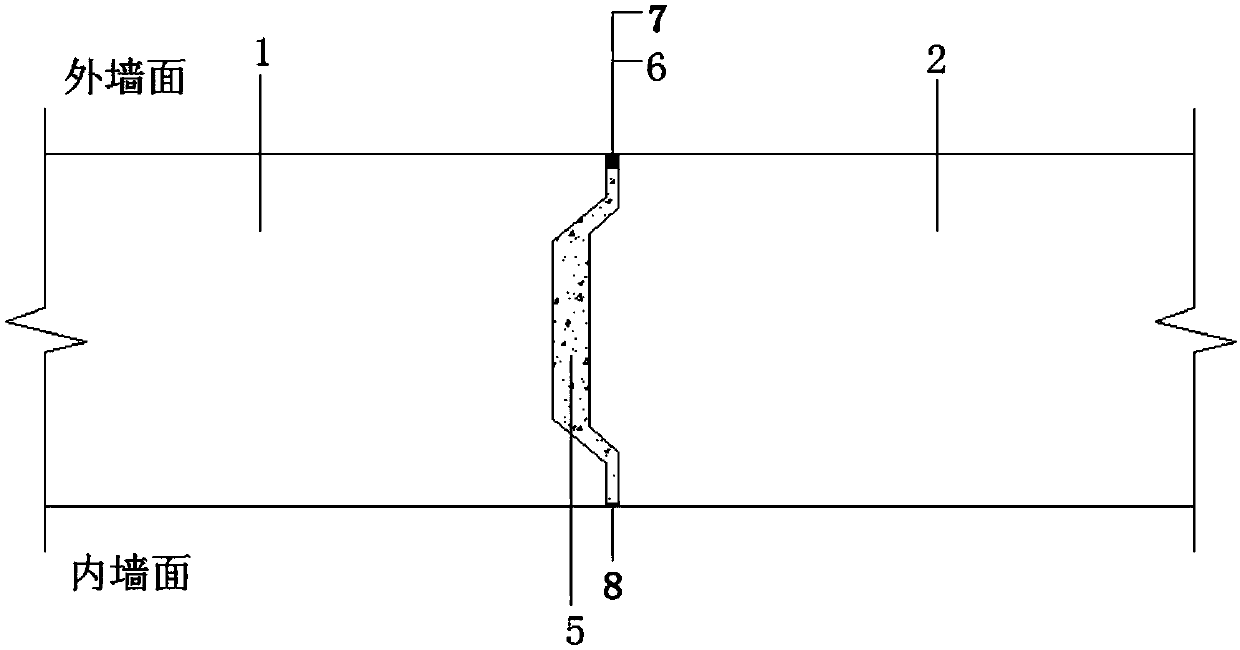

[0018] Such as figure 1 , 2 As shown, the prefabricated building prefabricated wall panel vertical joint grouting alveolar waterproof connection structure includes a plurality of prefabricated concrete prefabricated wall panels connected head to tail in sequence. In this example, the prefabricated concrete left wall panel 1 and assembly Prefabricated concrete prefabricated right wall panel 2 is taken as an example to illustrate the connection relationship between adjacent prefabricated concrete prefabricated wall panels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com