Circuit board function test device

A technology for functional testing and circuit boards, applied in electronic circuit testing, printed circuit testing, measuring devices, etc., and can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

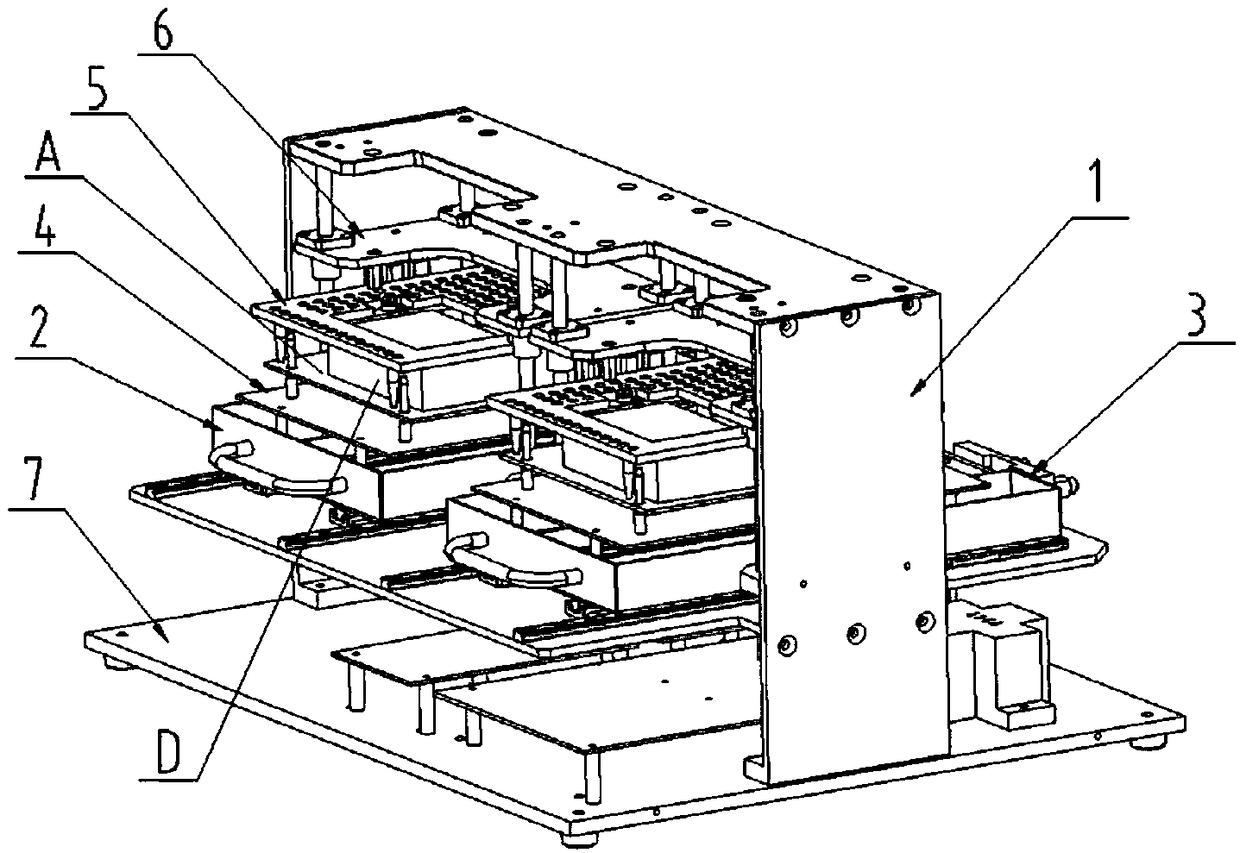

[0026] From figure 2 It can be seen that the circuit board function test device disclosed in this embodiment mainly includes a main support frame 1, a tray assembly 2, a tray limit assembly 3, a needle bed plate assembly 4, a crimping plate assembly 5, and an automatic crimping mechanism 6 and test chassis assembly 7. This embodiment is a double-station device, which can test two circuit boards at the same time. Therefore, two sets of the tray assembly, the tray limit assembly, the needle bed plate assembly, the crimping plate assembly, the automatic crimping mechanism and the test base plate assembly are connected to the main support frame.

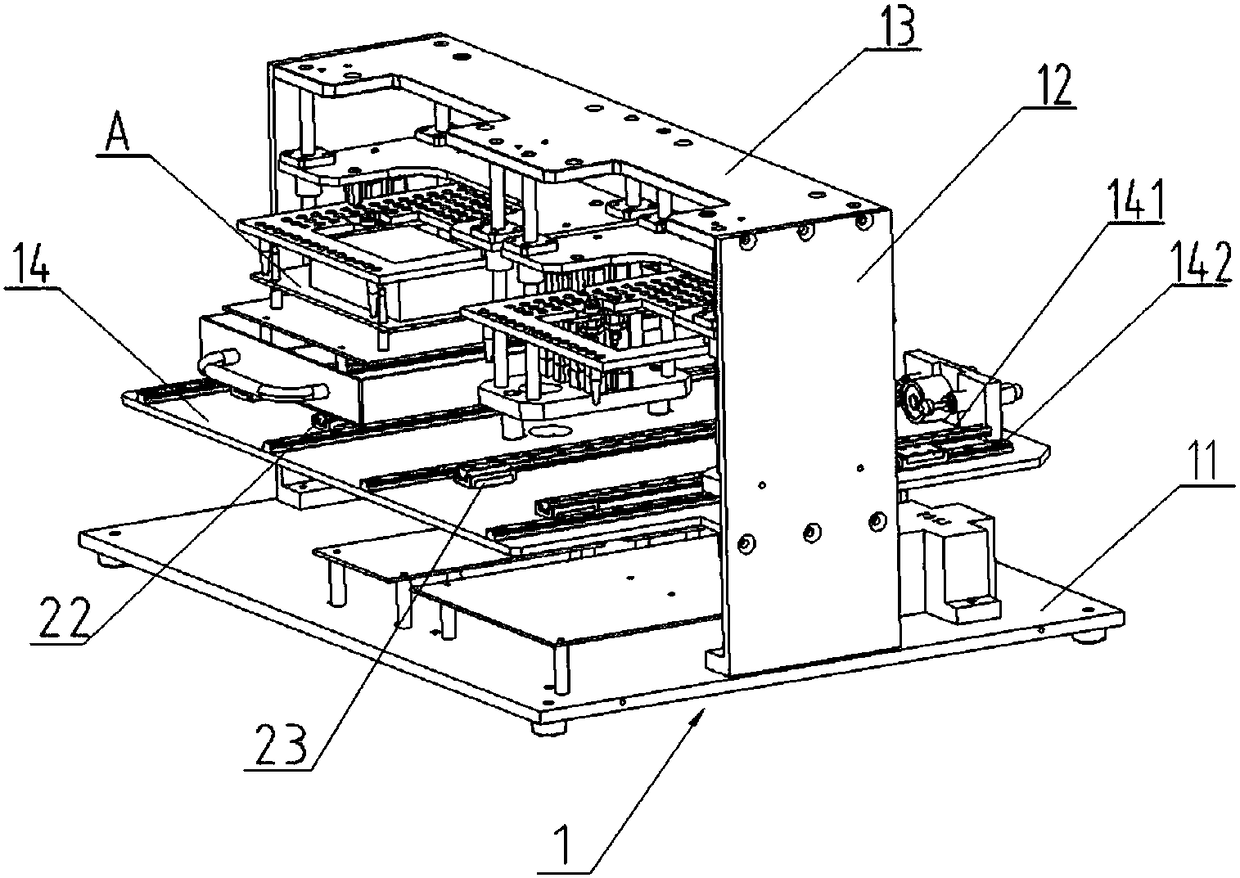

[0027] combine figure 2 and as image 3 It can be seen that the main support frame 1 includes a base plate 11 and a support frame connected thereto, the support frame includes a side vertical plate 12, an upper support plate 13, and a platform plate 14, and two side vertical plates 12 are symmetrically connected to the base plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com