An installation method for a tile-oriented distributed computing device

A technology of distributed calculation and installation method, applied in the direction of calculation, design optimization/simulation, instruments, etc., can solve the problems of increasing decoration cost, destroying the beauty of laying, and easy damage of floor tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

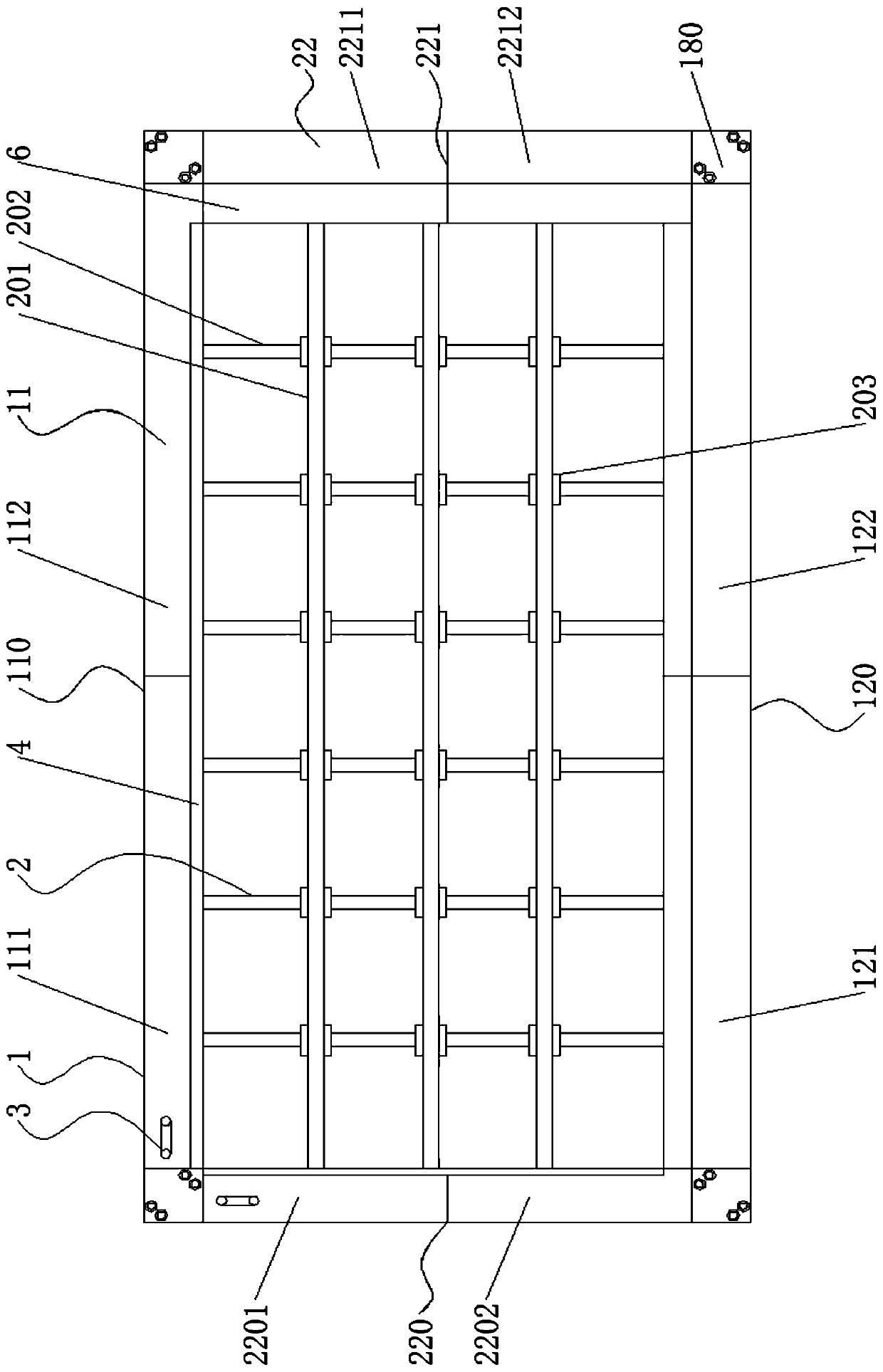

[0045] combine Figure 1-Figure 4 and Figure 7 As shown, a tile distribution calculation device disclosed in this embodiment includes a tile distribution simulation frame 1 and a tile distribution simulation rod group 2; the tile distribution simulation frame 1 is provided with several sets of tile distribution simulation rod groups vertically staggered 2;

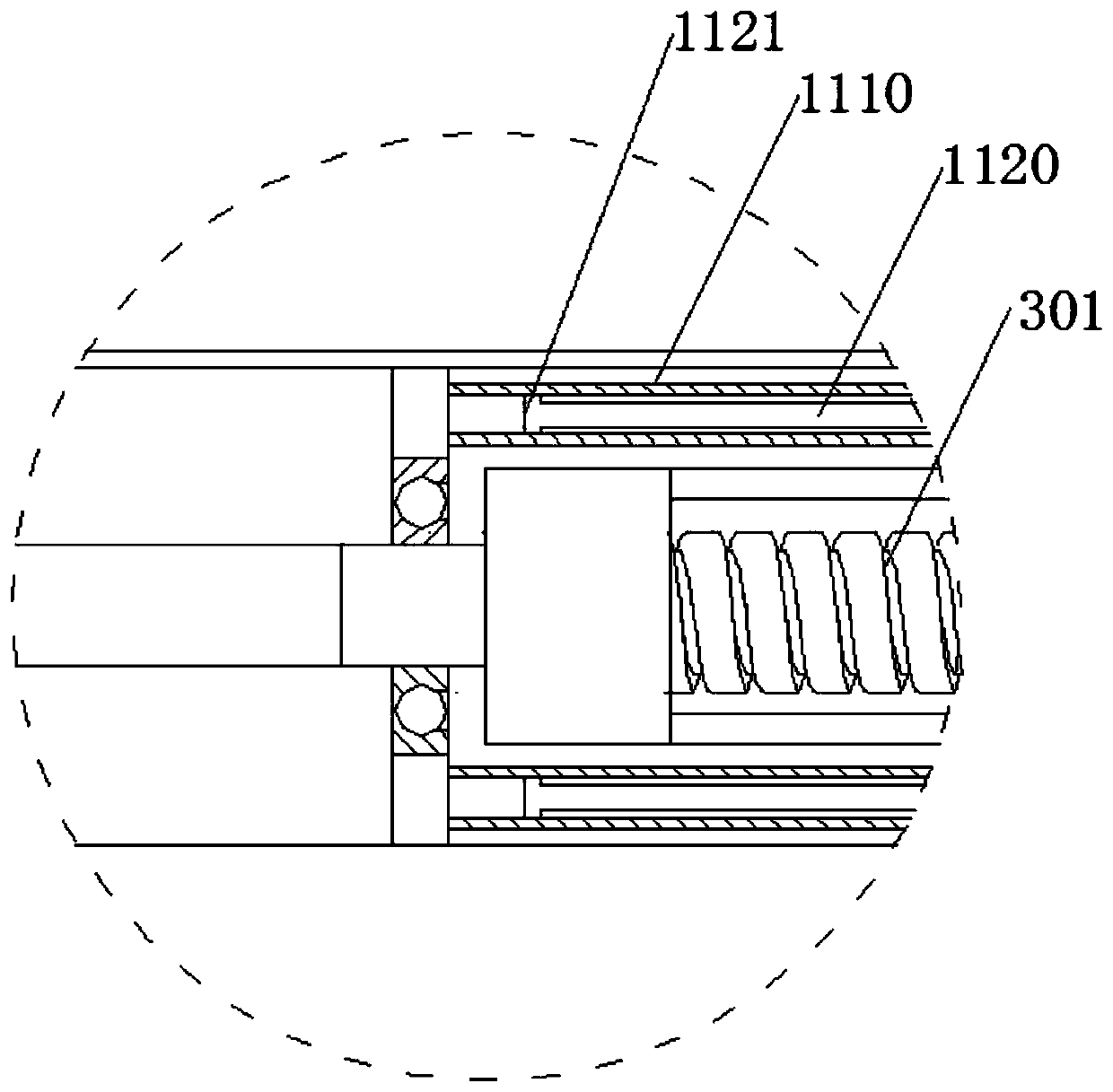

[0046] The tile distribution simulation frame 1 includes a simulation beam group 11 and a simulation vertical beam group 22; the simulation beam group 11 includes an active extension simulation beam 110 and a follow-up extension simulation beam 120, and the active extension simulation beam 110 includes a first beam 111 and the second crossbeam 112, the first crossbeam 111 and the second crossbeam 112 are arranged oppositely, the left end surface of the first crossbeam 111 is processed with four extension grooves 1110, the second crossbeam 112 and the Four sets of extension connecting rods 1120 are arranged on the opposi...

Embodiment 2

[0050] Such as Figure 5-6 As shown, on the basis of the first embodiment, both ends of the active extension simulation beam 110 and the follow-up extension simulation beam 120 are provided with a set of first extension connecting flaps 150, and the first extension connecting flaps 150 are A right-angled triangle wing plate, and a group of connection positioning columns 140 are arranged on the hypotenuse of the first extended connecting wing plate 150, and a group of second The extension connecting wing 160, the second extending connecting wing 160 is also a right-angled triangle wing, and corresponds to the size of the first extending connecting wing 150, and the hypotenuse of the second extending connecting wing 160 is processed with The connection positioning hole corresponding to the connection positioning column 140, the first extended connecting wing 150 and the second extended connecting wing 160 are detachably connected through the matching relationship between the con...

Embodiment 3

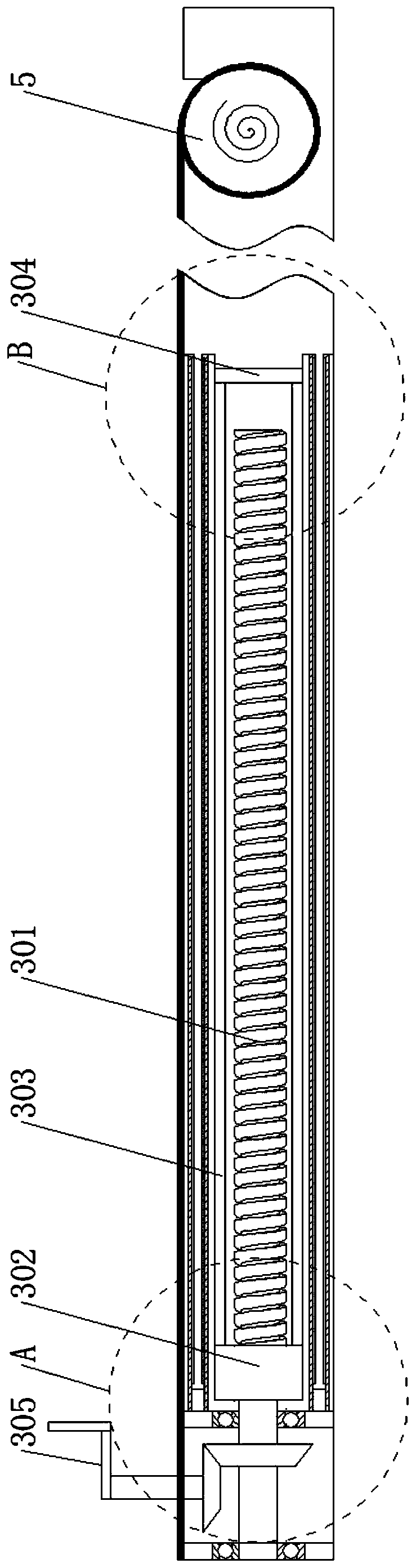

[0052] Such as Figure 2-4 On the basis of the second embodiment shown, the extension driving device 3 in this embodiment includes an extension screw 301, and a group of screw nuts 302 are arranged on the extension screw 301. Two sets of extension drive rods 303, the other ends of the two sets of extension drive rods 303 are fixedly connected with a set of extension push plates 304, the other end of the extension screw 301 is provided with a set of driven helical gears, the driven The helical gear meshes with a group of driving helical gears, the driving helical gear is fixedly connected with a group of driving handles 305, and the extended push plate 304 arranged inside the first crossbeam 111 is fixedly connected with the end of the second crossbeam 112; The extended push plate 304 inside the first vertical beam 2201 is fixedly connected with the end of the second vertical beam 2202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com