Layered film

A technology of laminating film and substrate layer, applied in the direction of coating, layered product, adhesive type, etc., can solve the problem of excessive adhesion of prism sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

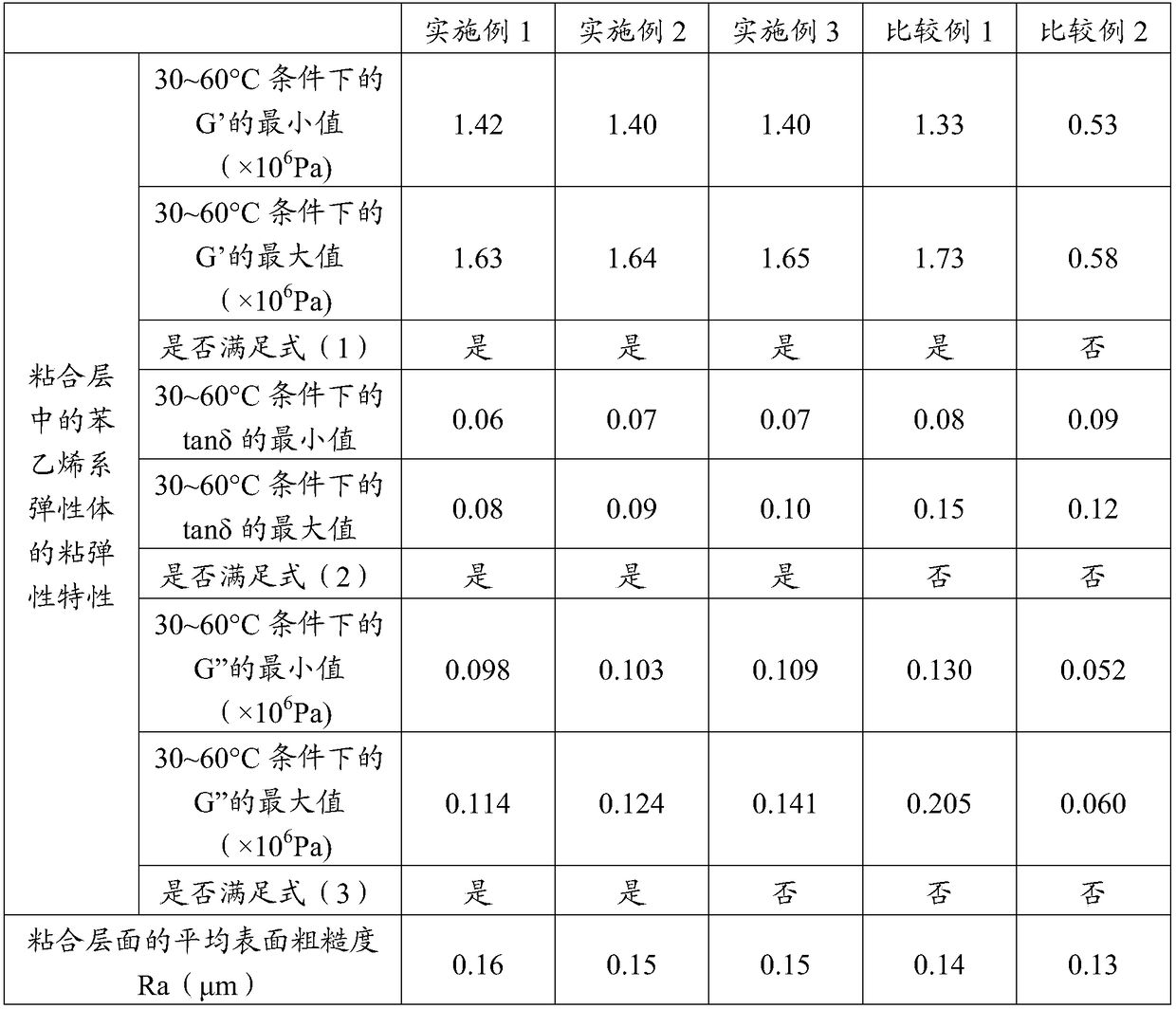

Embodiment 1

[0097] As the styrene-based elastomer, 5 parts by mass of FTR6125 made by Mitsui Chemicals Co., Ltd. and 5 parts by mass of FTR6125 made by Arakawa Chemical Industry Co., Ltd. were added to 90 parts by mass of Elastomer S1606 (50 mass % of styrene) made by Asahi Kasei Chemical Co., Ltd. The ratio of ALCON P100 was dry mixed to prepare an adhesive layer resin composition.

[0098] As the base material layer, a commercially available isotactic polypropylene (homopolypropylene) having a melt flow rate (MFR, 230° C., 2.16 kg) of 4 g / 10 minutes was used.

[0099]Into two types of two-layer T-molded film machines having two single-screw extruders with a compression ratio of 4.2 and L / D=25, the above-mentioned resin composition for the adhesive layer and the resin for the substrate layer were injected so as to make the adhesive layer. The laminate side was casted so that it was brought into contact with a metal cooling roll controlled at a temperature of 30°C, cooled and solidified t...

Embodiment 2

[0101] A film having an overall thickness of 40 μm was obtained in the same manner as in Example 1, except that the composition of the adhesive layer of Example 1 was changed as shown below.

[0102] · Elastomer S1606 (50% by mass of styrene) manufactured by Asahi Kasei Chemical Co., Ltd.: 80 parts by mass

[0103] · TUFTEC H1052 (20% by mass of styrene) manufactured by Asahi Kasei Chemical Co., Ltd.: 10 parts by mass

[0104] · FTR6125 manufactured by Mitsui Chemicals Co., Ltd.: 5 parts by mass

[0105] · ALCON P100 manufactured by Arakawa Chemical Industry Co., Ltd.: 5 parts by mass.

Embodiment 3

[0107] A film having an overall thickness of 40 μm was obtained in the same manner as in Example 1, except that the composition of the adhesive layer of Example 1 was changed as shown below.

[0108] · Elastomer S1606 manufactured by Asahi Kasei Chemical Co., Ltd.: 70 parts by mass

[0109] · TUFTEC H1052 manufactured by Asahi Kasei Chemical Co., Ltd.: 20 parts by mass

[0110] · FTR6125 manufactured by Mitsui Chemicals Co., Ltd.: 5 parts by mass

[0111] · ALCON P100 manufactured by Arakawa Chemical Industry Co., Ltd.: 5 parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com