Internal and external welding device for welding steel tube and flange

A flange welding and steel pipe technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of inability to adjust, difficult to adjust automatically, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

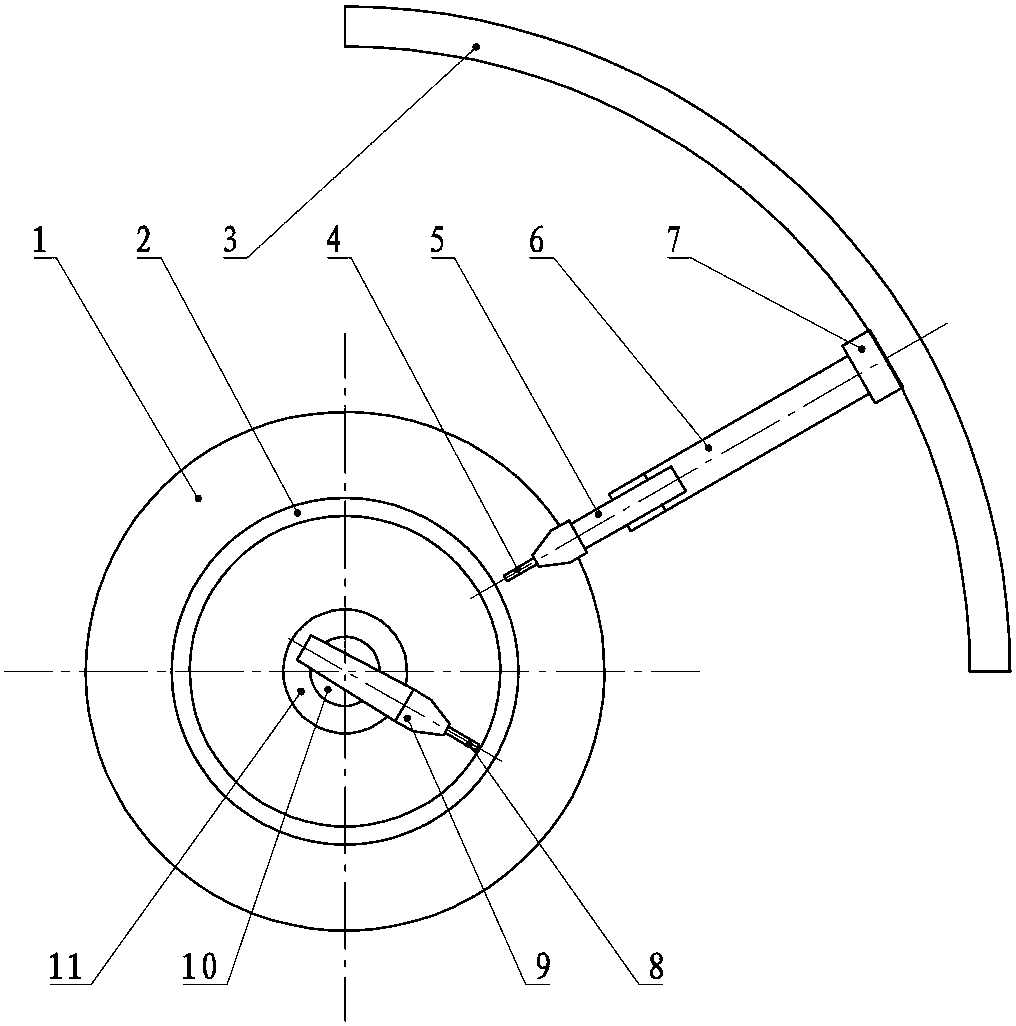

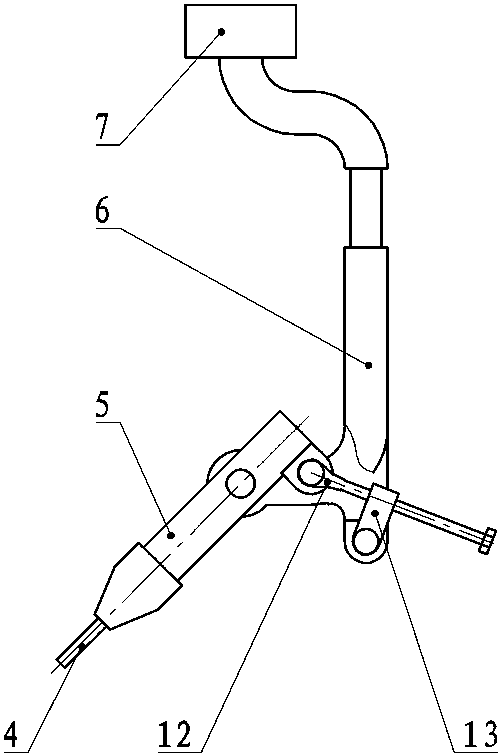

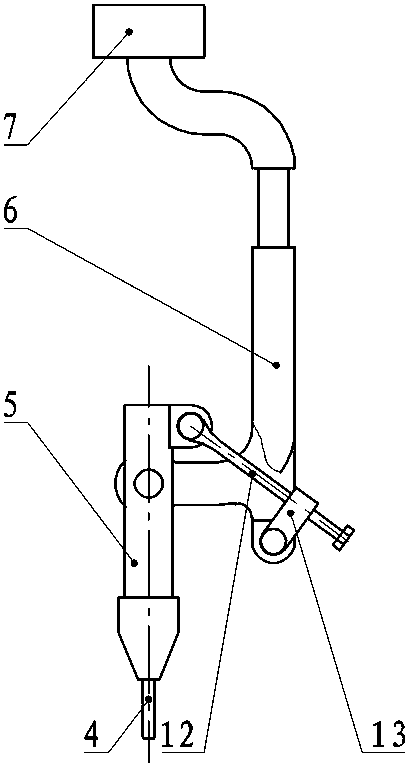

[0014] Such as figure 1 , 2 , 3, 4, and 5, the internal and external welding device for steel pipe 2 and flange 1 welding provided by the present invention has a frame, and a steel pipe and a flange assembly device are installed on the frame, and the assembly device includes a steel pipe and a flange The rolling device is equipped with an internal welding device and an external welding device on the frame. Both the inner welding device and the outer welding device are formed by installing the welding torch on the welding operation mechanism. The welding manipulation mechanism includes a mechanism for adjusting the spatial position such as height and axial direction and a mechanism for adjusting the angle.

[0015] The welding control mechanism of the external welding device has a front and rear slide rail fixed on the frame, and the front and rear slide rails are installed on the front and rear slide rails to form a front and rear slide mechanism. The moving direction of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap