Impeller blade forming and assembling workstation

A technology of impeller blades and workstations, applied in assembly machines, metal processing, manufacturing tools, etc., can solve the problems of low efficiency, product benefits falling again and again, and efficiency not meeting requirements, so as to reduce production time and labor. The effect of operating volume and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

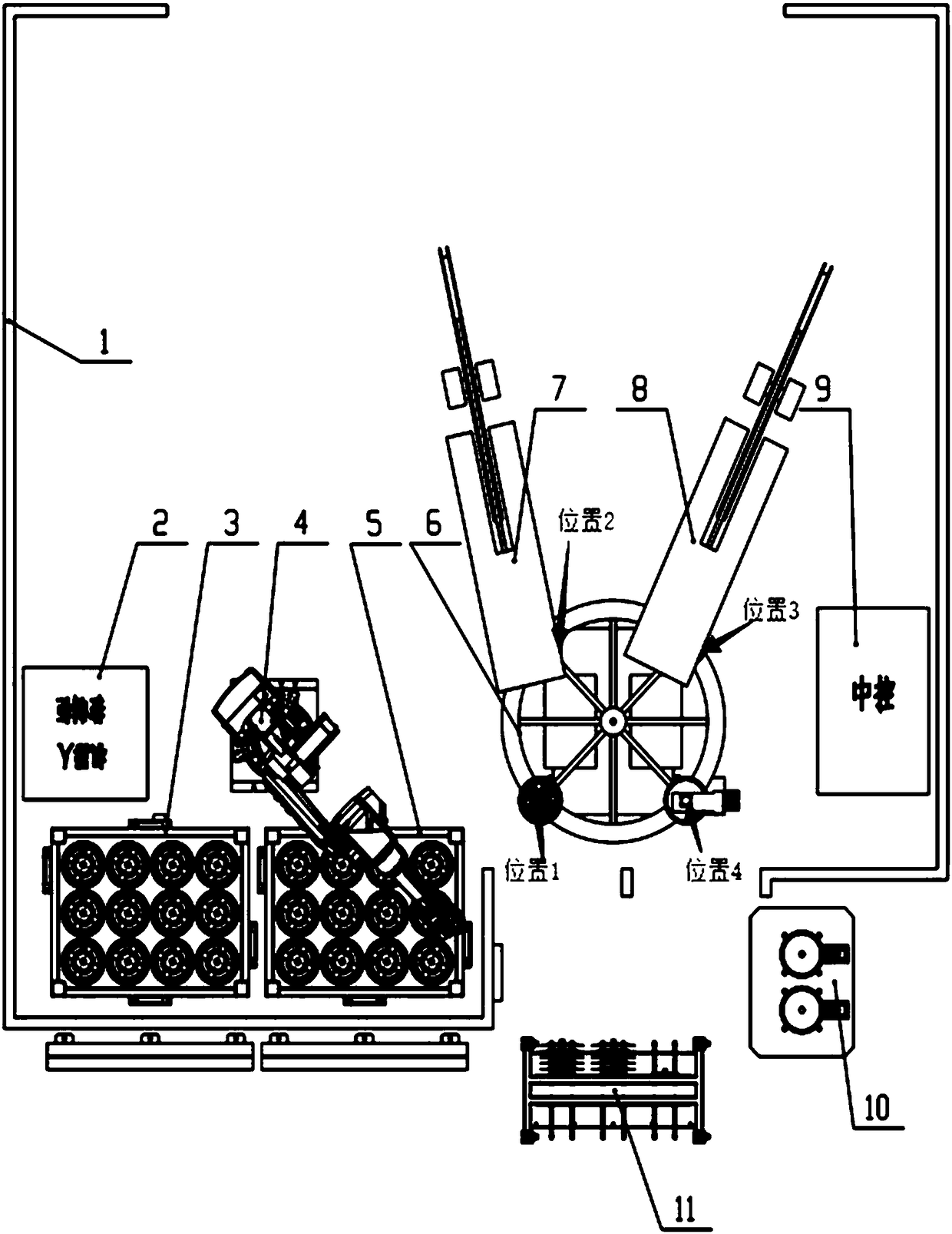

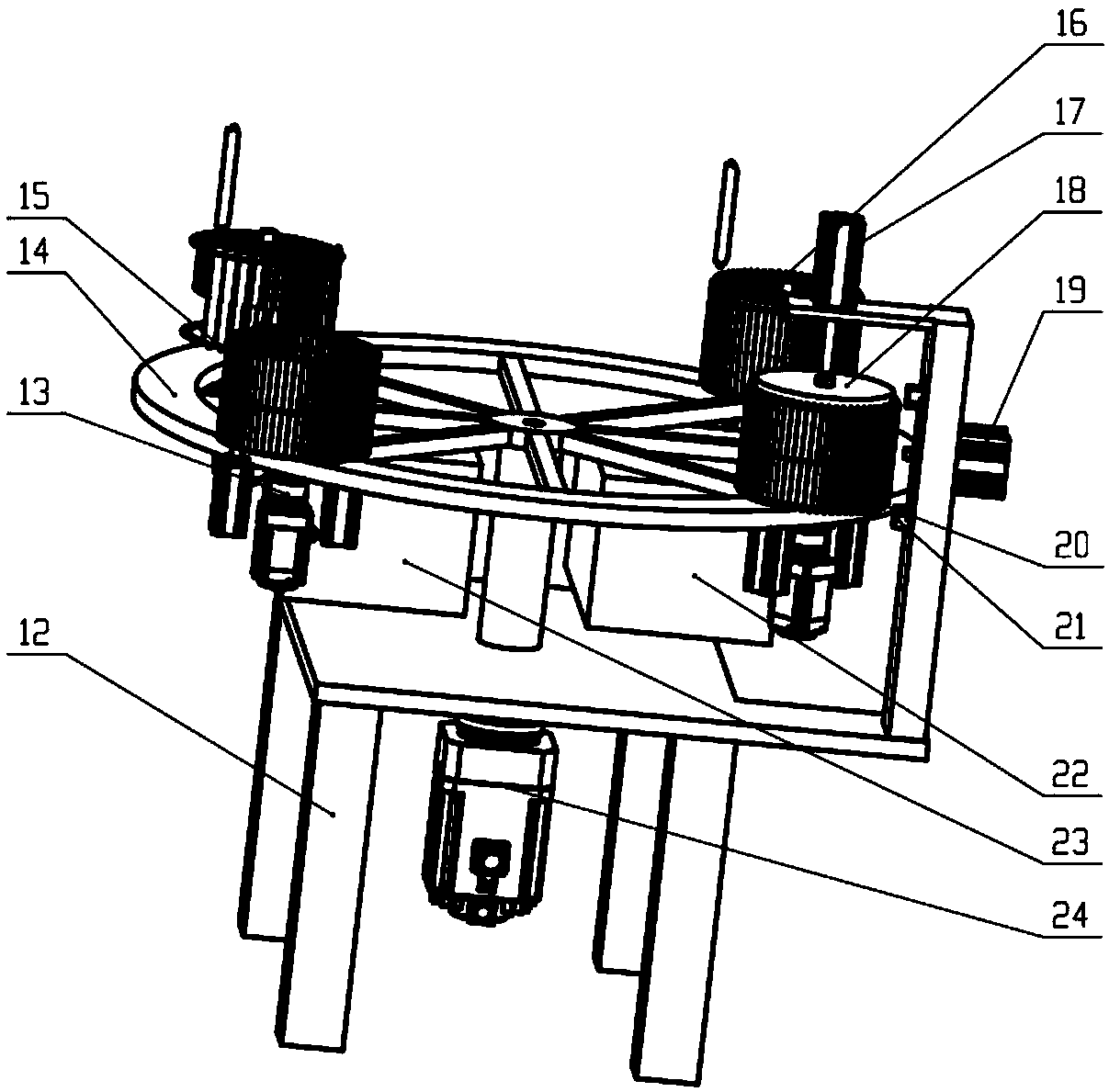

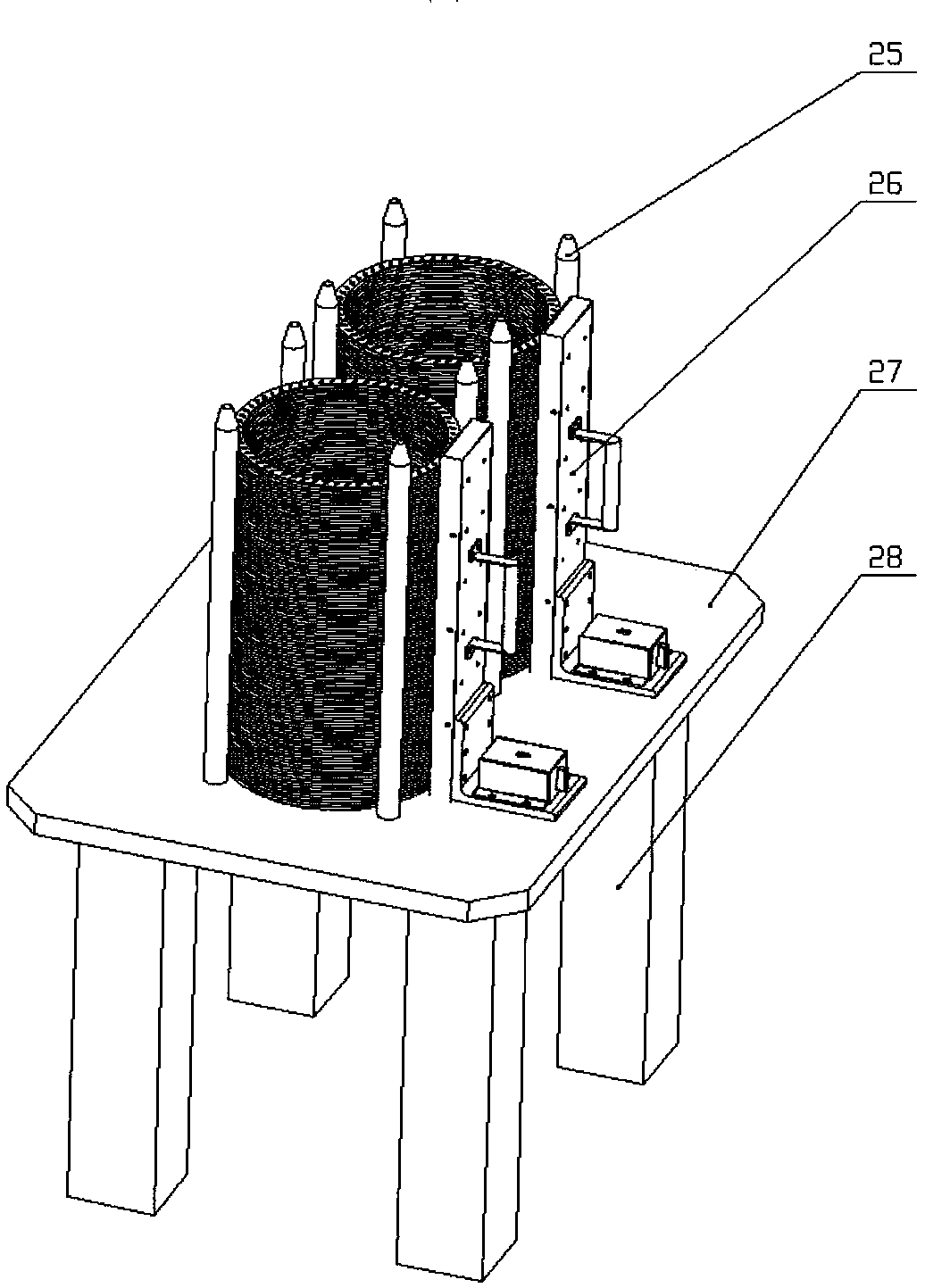

[0023] As an embodiment of this patent, such as Figure 1-6 As shown, in the impeller blade forming and assembly workstation, there are two inserting machines, and four indexing and lifting modules, which are recorded as position 1, position 2, position 3, and position 4. There are two finished product storage box assemblies, and there are two cavities, which are respectively equipped with a front piece and a back piece.

[0024] The specific position distribution is as follows: the storage box assembly A and the storage box assembly B are located at the lower left of the overall layout, the robot assembly is located above the storage box assembly A and the storage box assembly B, and the impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com