A spinning device and spinning method with full control of fibers in the drafting zone

A drafting zone and fiber technology, which is applied in the field of full-process fiber control spinning devices in the drafting zone, can solve the problems of increasing production costs and increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

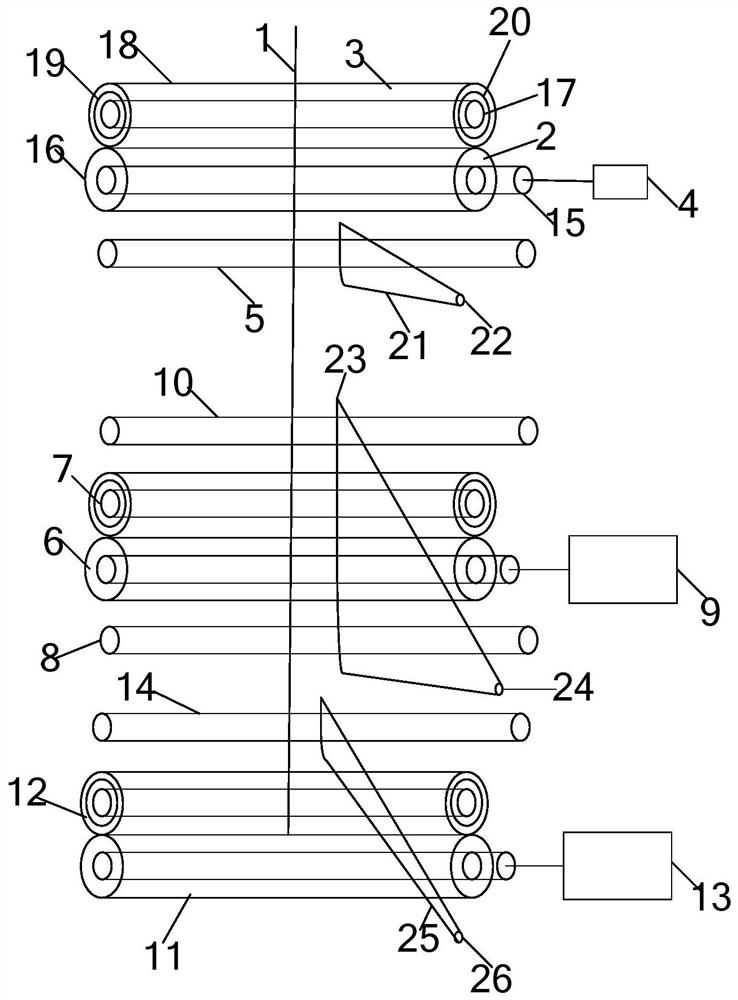

[0025] Depend on figure 1 As shown, a full-range control spinning device for fibers in the drafting area includes a rear drafting roller pair composed of a rear roller 2 and a rear rubber roller 3, and a middle draft roller pair composed of a middle roller 6 and a middle rubber roller 7. , the front drafting roller pair that is made up of front roller 11 and front rubber roller 12.

[0026] Back roller 2, middle roller 6, and front roller 11 have the same structure. Back roller 2, middle roller 6, and front roller 11 include roller shaft 15. Roller shaft 15 is a solid cylindrical structure. Each spindle on roller shaft 15 corresponds to The fixed sleeve on the spindle position has a roller sleeve 16, and the roller sleeve 16 is integrated and fixedly connected with the roller shaft 15. The roller sleeve 16 and the roller shaft 15 are made of steel or iron. The left end of the roller shaft 15 of the rear roller 2 stretches out from the left side of the roller sleeve 16 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com