One-stop multifunctional assembly test line

A multi-functional, test-line technology, applied in the direction of measuring devices, mechanical valve testing, fluid tightness testing, etc., can solve the problems of lack of continuity, low resource utilization, labor and time, etc., to achieve strong consistency, Improved product quality and multifunctional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

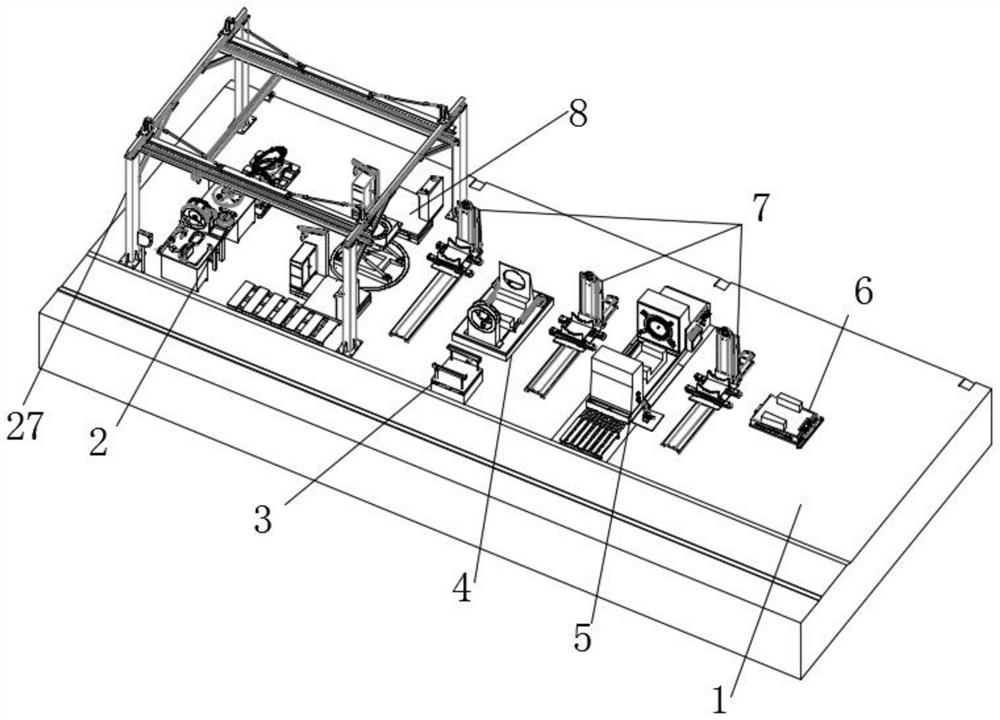

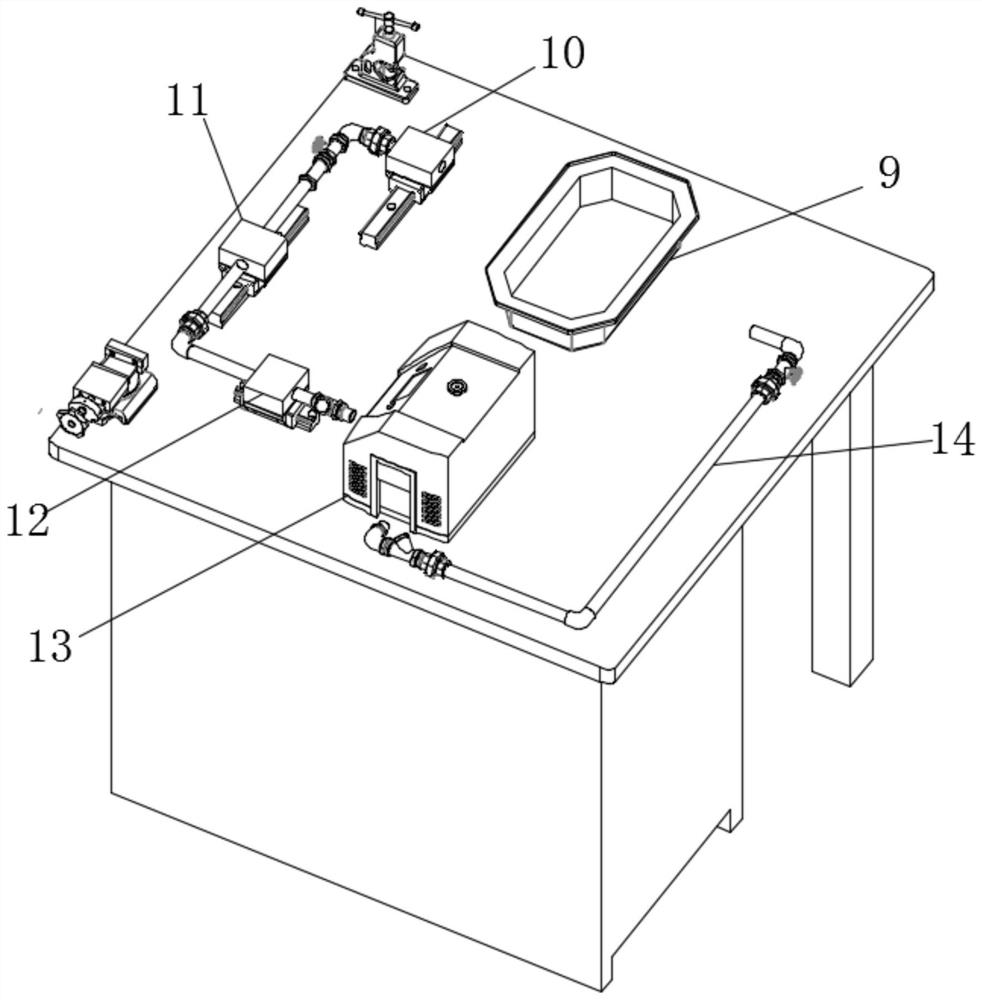

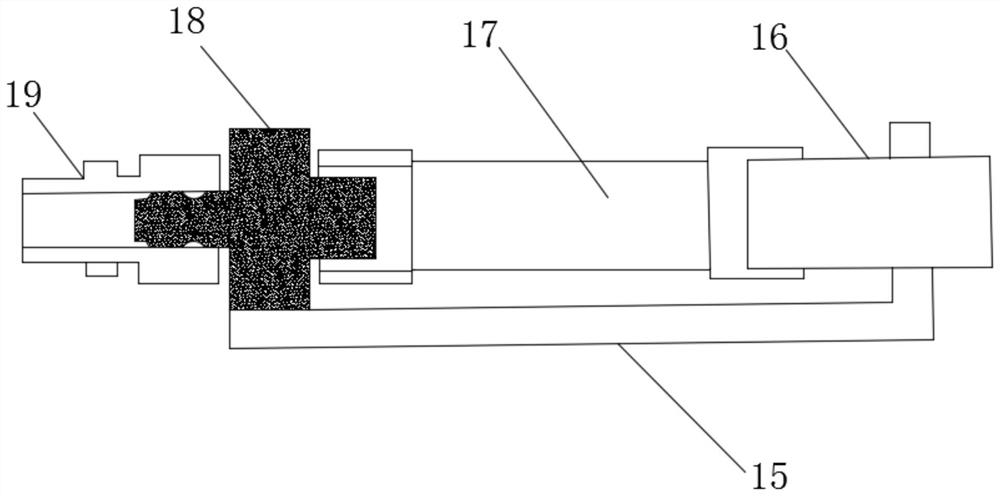

[0021] Such as Figure 1-5 As shown, the present invention provides a technical solution: a one-stop multifunctional assembly test line, including a working table 1, a cargo handling area 27 is fixedly installed on the top side of the working table 1, and a valve component pre-assembly is arranged inside the cargo handling area 27 Area 2 and valve body assembly area 8, the top of the worktable 1 is equidistantly provided with the conveying robot arm 7, and the valve plate test area 4 and the valve body test area 5 are fixedly installed between the adjacent conveying robot arms 7, and the valve plate test area 4 There is a valve body rework area 3 on one side, a trolley system 6 is fixedly installed on the top of the other side of the workbench 1, a controller is fixedly installed on the side of the workbench 1, and the valve component pre-assembly area 2 includes a part placement box 9 and an airtight Detector 13, the air-tightness detector 13 is provided with an air inlet sid...

Embodiment 2

[0023] As shown in Figure: 4-5, valve body test area 5 comprises test cell body 20, and test cell body 20 interior is provided with water recovery tank 23 and water filter tank 25, is provided with between water recovery tank 23 and water filter tank 25 The laminar flow filter wall 24, the top of the test tank 20 is provided with a movable metal mesh 22, the top of the movable metal mesh 22 is fixedly installed with a centrifugal pump 21, the inside of the water filter pool 25 is provided with a filter 26, and the cargo handling area 27 is provided with a lift The control system and sliding control system, the lifting system and the sliding control system are electrically connected to the controller respectively, and the cart system 6 includes a drive unit, a control chip unit, an obstacle avoidance sensor, an alarm device, a power switch, a controller and an operation panel, and a valve Body test area 5 also includes water inlet filter, check valve, stop valve, multi-stage cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com