Lifting and slipping construction method of steel truss structure with large span and unequal height supports

A steel truss and large-span technology, which is applied in the field of hoisting and sliding construction methods of high-support steel truss structures, can solve problems such as the difficulty of hoisting and positioning construction cranes, achieve smooth and controllable sliding, reduce the workload of high-altitude installation, Guarantee the effect of stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Construction preparation:

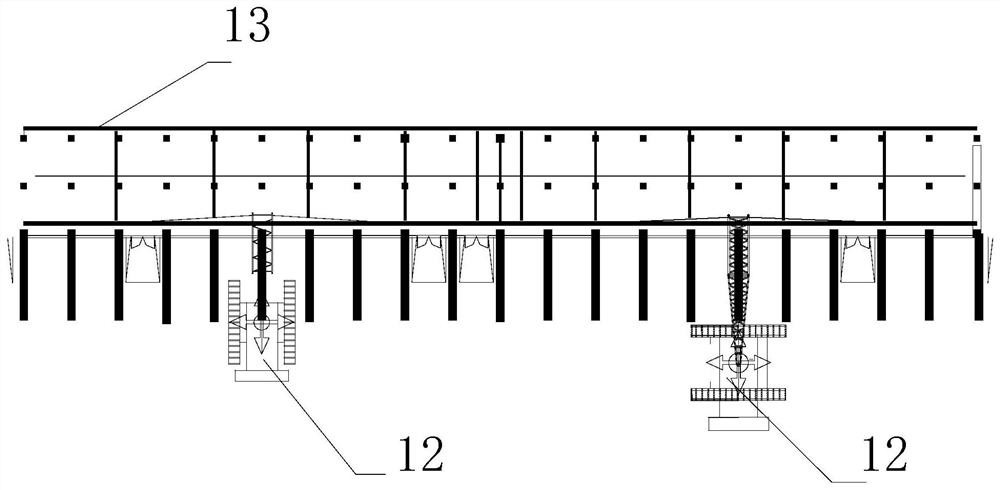

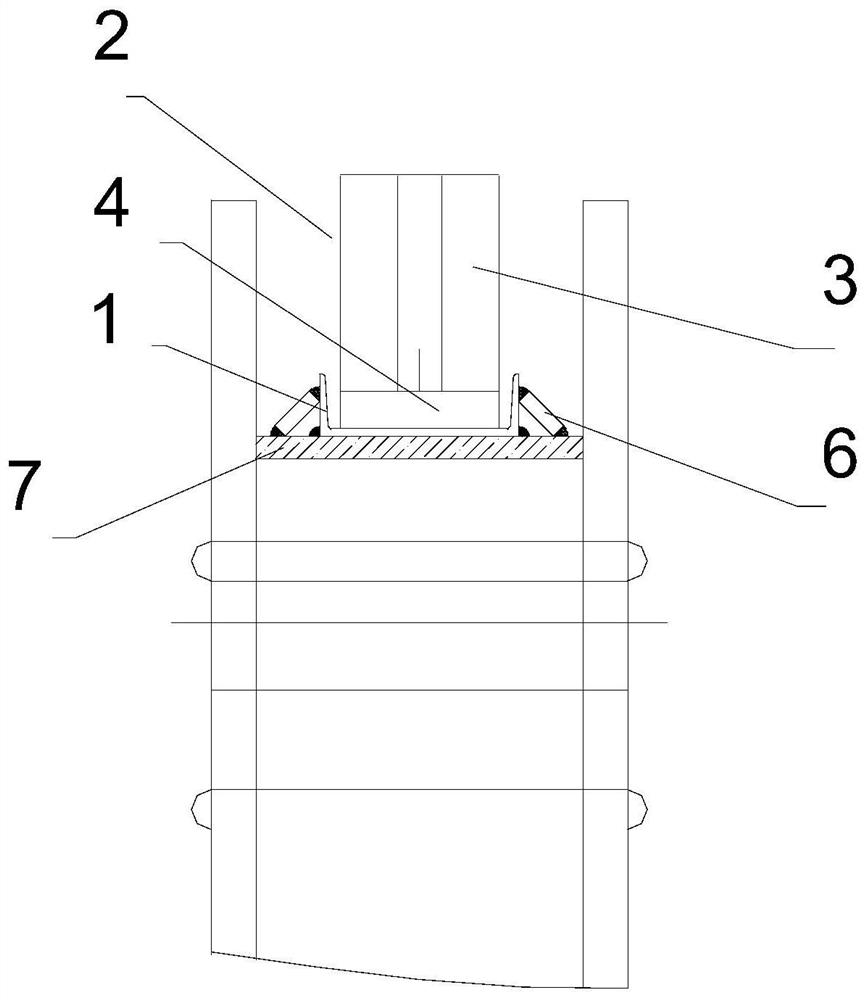

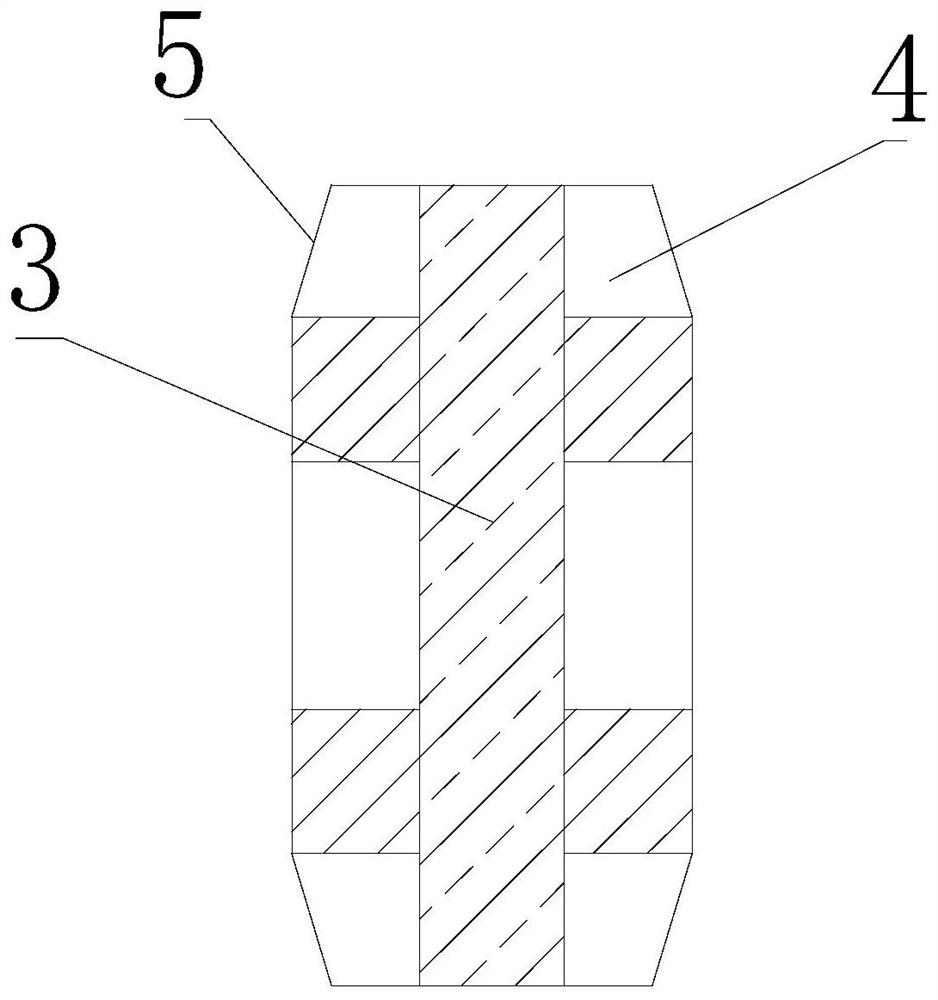

[0042] 1. Equipment selection and layout. According to the self-weight and size of the steel truss, combined with the situation of the lifting equipment 12 in the market and the contract cost requirements, the type and quantity of the lifting equipment 12 are determined. According to the self-weight and size of the steel truss, calculate the mass of the steel truss to be slid and the friction force during the sliding process, select the models of hydraulic jacking equipment, hydraulic pump source equipment, computer synchronous control and sensor detection system, and determine the Arrangement of push points and sliding scheme. During the sliding process, the thrust exerted by the pusher and the friction force F between all the sliding shoes 2 and the slide rails are balanced. After force analysis and calculation, due to the heavy sliding weight of the middle track, a push point is arranged every two trusses on the middle track.

[0043] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com