A real-time measuring device for drill bit pressure during construction of cement-soil mixing pile

A cement-soil mixing pile and drill bit pressure technology, applied in the field of geotechnical engineering, can solve the problems of not considering the distribution characteristics of the soil, the inability to perceive the change of the soil layer, and the inability to automatically identify the soil layer, etc., so as to improve the foundation effect and reduce the construction cost , The effect of reducing cement waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

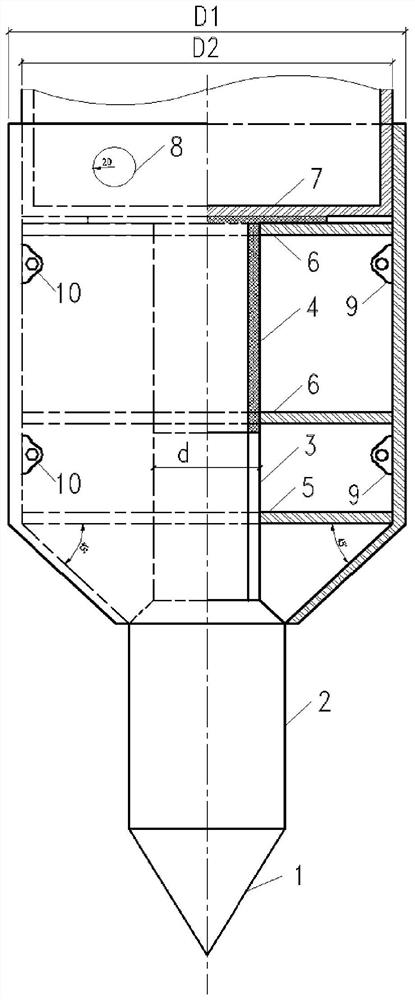

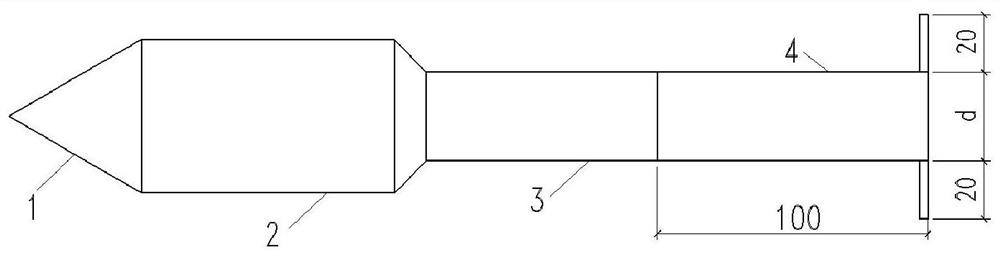

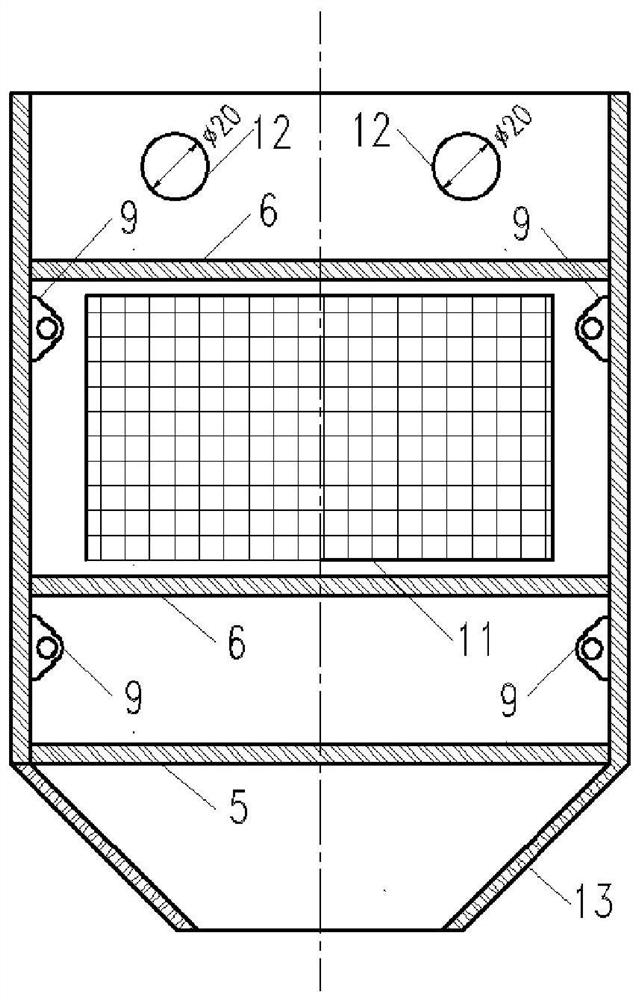

[0024] Such as figure 1 As shown, a real-time measurement device for drill bit pressure during the construction of cement-soil mixing piles includes a single-bridge static penetration probe and a special joint. The single-bridge static penetration probe is fixed to the drill pipe of the cement-soil mixing pile through a special joint 7 the end of. figure 2 The refitted single-bridge static penetration probe used in this embodiment includes a probe cone 1, a probe sleeve 2, a probe tube 3 and an elongated steel tube 4. The elongated steel tube has a square cross-section and a length of 100mm. Weld a pair of steel bars with a length of 20mm and a width of 10mm symmetrically. The main body of the special joint is cylindrical, and it is formed by joining two completely symmetrical parts 13 through four bolts 10. image 3 For split part 13, Figure 4 For No. 1 liner 5, Figure 5 No. 2 liner 6, No. 1 liner 5 and No. 2 liner 6 are used to fix the single-bridge static penetrating...

Embodiment 2

[0026] Such as figure 1 As shown, a real-time measurement device for drill bit pressure during the construction of cement-soil mixing piles includes a double-bridge static penetration probe and a special joint. The double-bridge static penetration probe is fixed to the drill pipe of the cement-soil mixing pile through a special joint 7 the end of. figure 2 The refitted double-bridge static penetration probe used in this embodiment includes a probe cone 1, a probe sleeve 2, a probe tube 3 and an elongated steel tube 4. The elongated steel tube has a square cross-section and a length of 100mm. Weld a pair of steel bars with a length of 20mm and a width of 10mm symmetrically. The main body of the special joint is cylindrical, and it is formed by joining two completely symmetrical parts 13 through four bolts 10. image 3 For one of the split parts 13, Figure 4 For No. 1 liner 5, Figure 5 No. 2 liner 6, No. 1 liner 5 and No. 2 liner 6 are used to fix the double-bridge static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com