Liquid-enhanced non-contact mechanical seal structure

A non-contact, mechanical seal technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of end face wear, high viscosity fluid can not lubricate and dissipate heat, insufficient seal life, etc., to reduce heat generation. , good elastic state, the effect of reducing operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

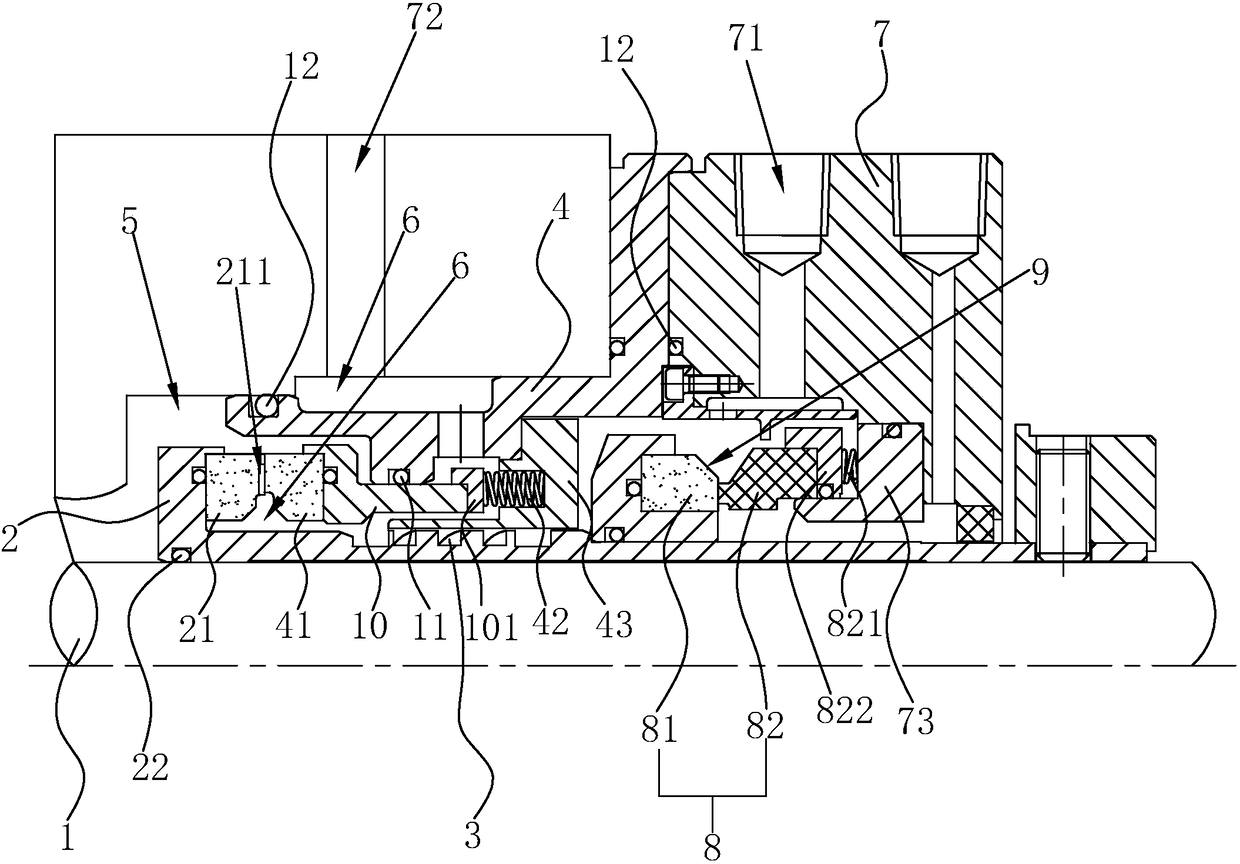

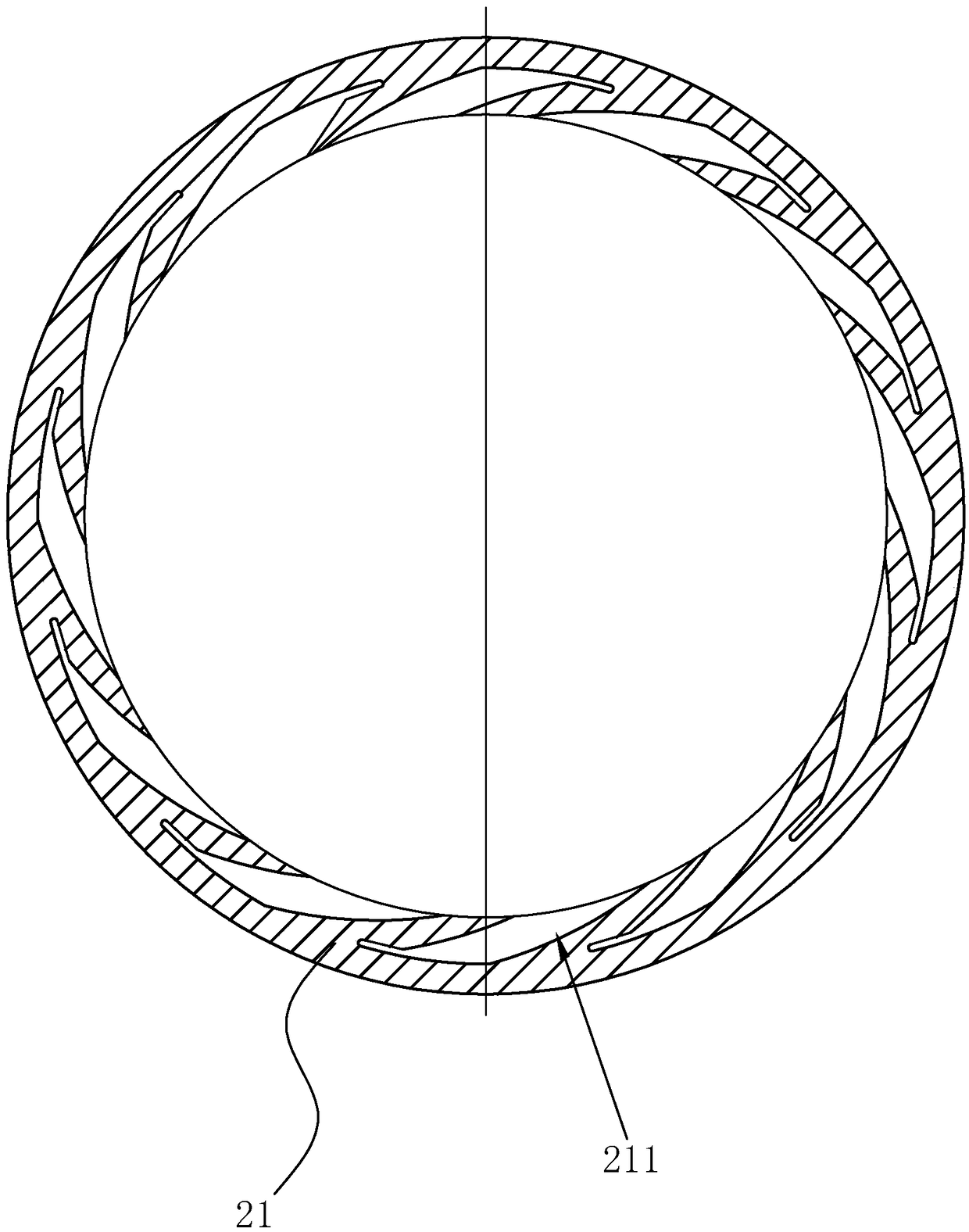

[0033] Such as figure 1 , 2 As shown, a liquid-enhanced non-contact mechanical seal structure includes a sleeve 2 sleeved and fixed on the rotating shaft 1, an inner gland 4 fixed on the pump cavity, and one end of the sleeve 2 is provided with a dynamic The sealing ring 21, the inner gland 4 is provided with a static sealing ring 41 sliding axially along the shaft sleeve 2, the static sealing ring 41 is used for sealing cooperation with the dynamic sealing ring 21; the static sealing ring 41 and the inner gland 4 are arranged There is a first elastic member, and the first elastic member makes the static sealing ring 41 always have a tendency to move toward the moving sealing ring 21 side. The end surface of the dynamic seal ring 21 facing the static seal ring 41 or the end surface of the static seal ring 41 facing the dynamic seal ring 21 is provided with an annular groove 211; in this embodiment, the annular groove 211 is arranged on the inner diameter side of the dynamic s...

Embodiment 2

[0042] The main difference between this embodiment and Embodiment 1 is that: figure 1 , 2 As shown, the ring groove 211 is arranged on the inner diameter side of the static seal ring 41 and communicates with the low-pressure chamber 6. in the opposite direction.

[0043] Specific working process: After the rotating shaft 1 is started to drive the shaft sleeve 2 to rotate, a clean low-pressure liquid is introduced into the inlet 71. At this time, the clean low-pressure liquid circulates in the low-pressure chamber 6 and enters the ring groove 211, and the dynamic sealing ring 21 and the The static sealing ring 41 separates and enters the high-pressure chamber 5, ensuring that the dynamic sealing ring 21 and the static sealing ring 41 always work in a clean fluid, and avoiding the particle impurities or high-viscosity medium in the high-pressure chamber 5 from affecting the sealing operation. The rotating shaft 1 drives the dynamic sealing ring 21 to rotate. Since the dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com