Equipment abnormality detecting method, device and system, air conditioner and storage medium

A technology for equipment abnormality and detection methods, which is applied in mechanical equipment, lighting and heating equipment, heating and ventilation control systems, etc., can solve the problems of low equipment quality inspection efficiency and abnormal detection methods, avoid potential risks and improve safety. performance, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

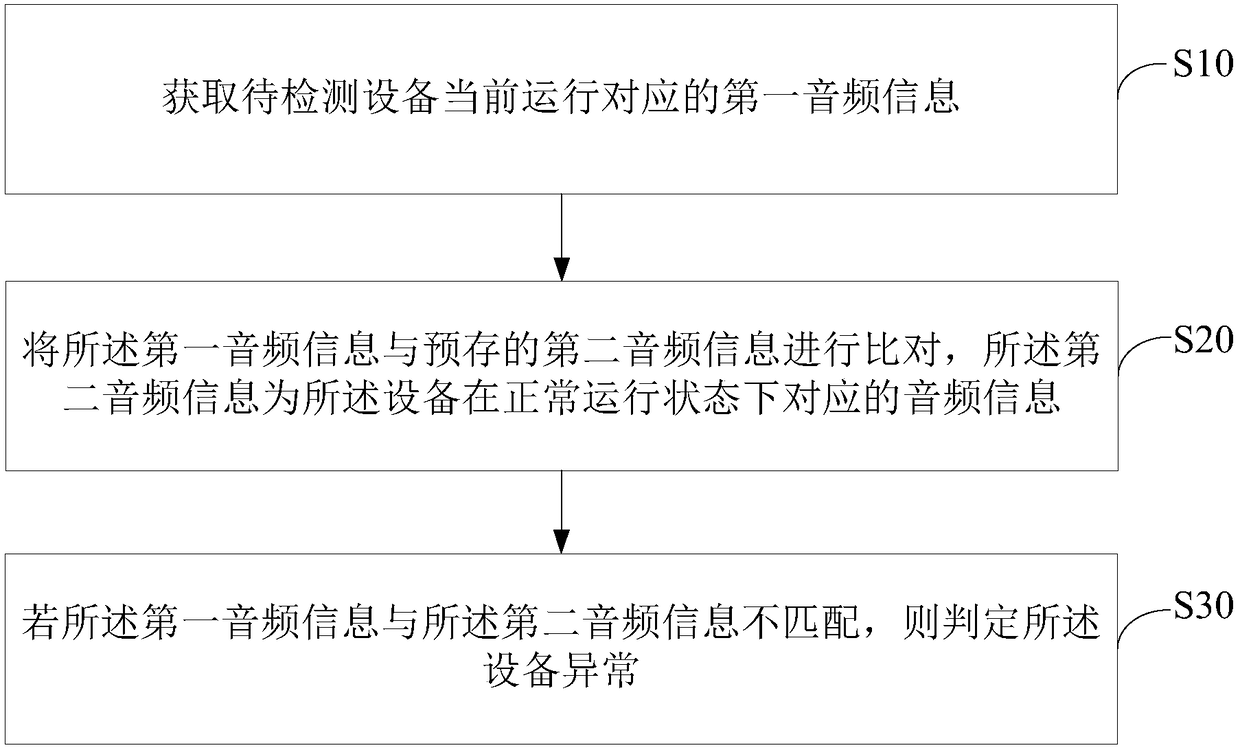

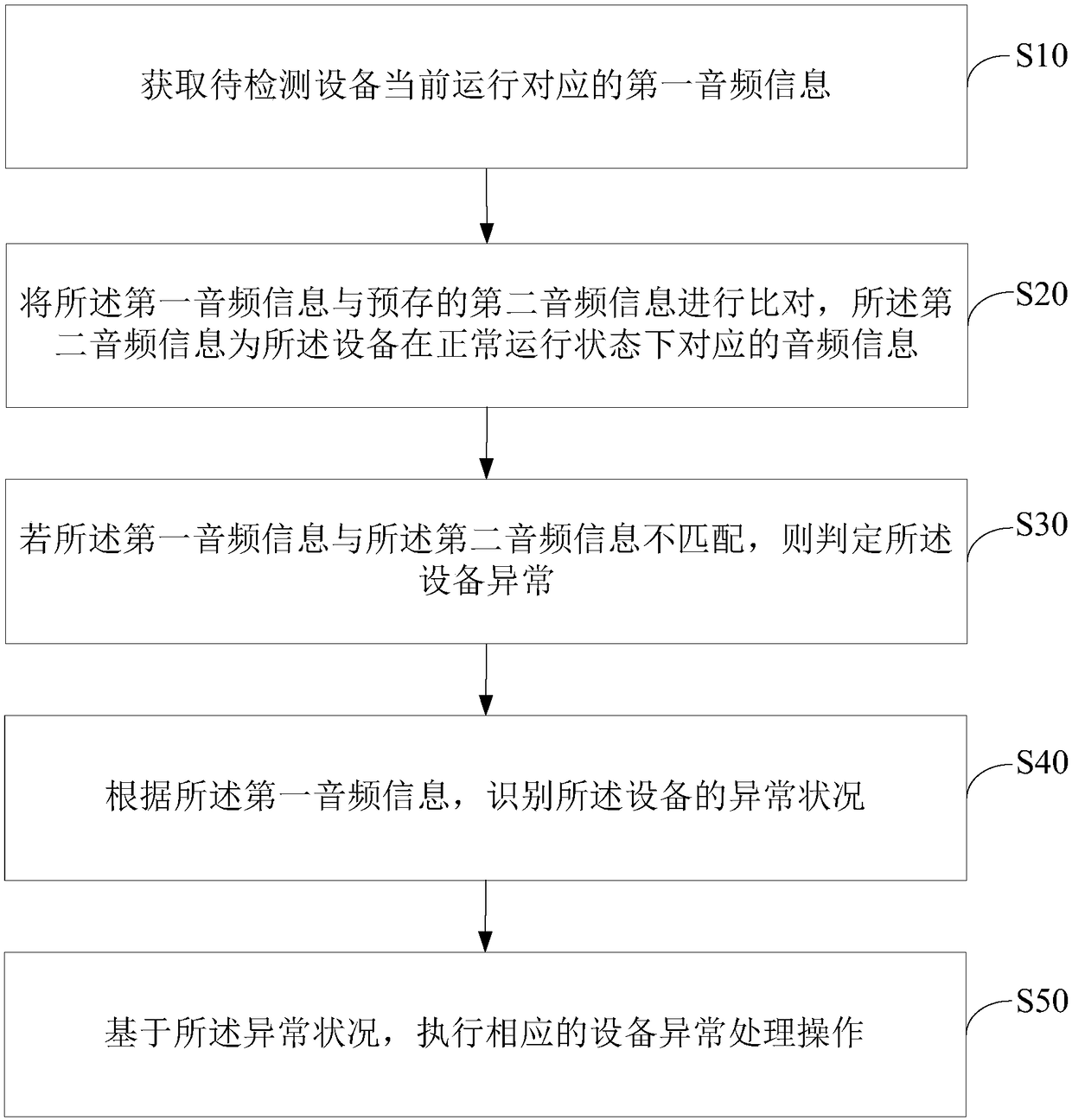

[0048] The solution of the embodiment of the present invention is mainly: by obtaining the first audio information corresponding to the current operation of the device to be detected, and comparing the first audio information with the pre-stored second audio information corresponding to the device in normal operation, If the first audio information does not match the second audio information, it is determined that the device is currently abnormal, thereby realizing timely and accurate quality inspection of the device, and the quality inspection process does not need to rely on manual operation. Through the technical solutions of the embodiments of the present invention, the problem that the quality inspection efficiency of equipment is not high is solved.

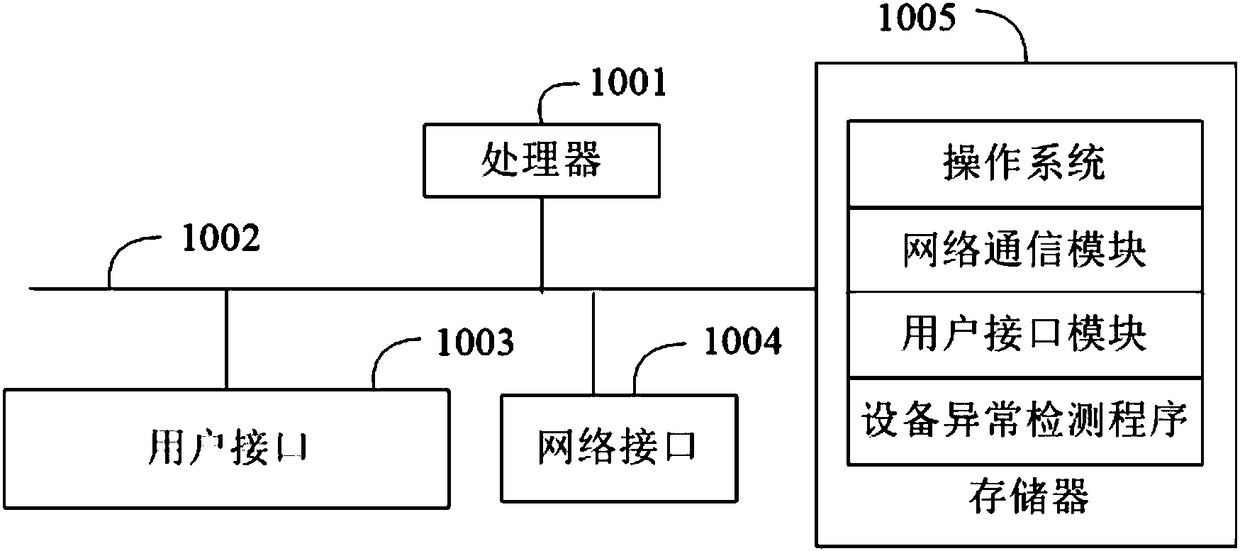

[0049] In order to better understand the above-mentioned tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com