Double pressure-sensitive revising type transformer oil level indicator

A transformer oil and oil level gauge technology, applied in the field of transformers, can solve the problems of unable to monitor the oil level remotely, the floating ball jamming, and affecting the reading, so as to realize the remote reading of the oil level, reduce the failure rate of the device, and improve the reliability performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

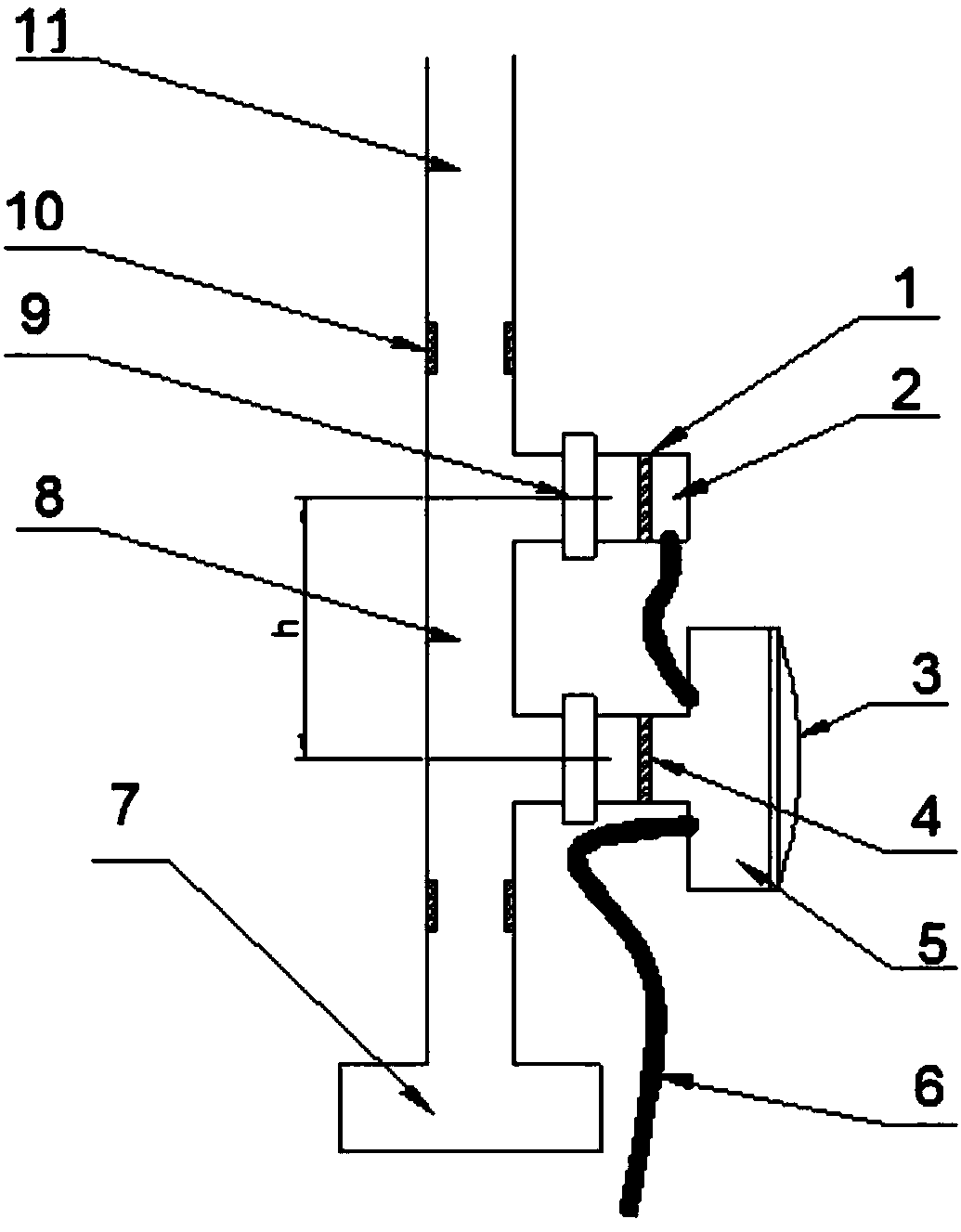

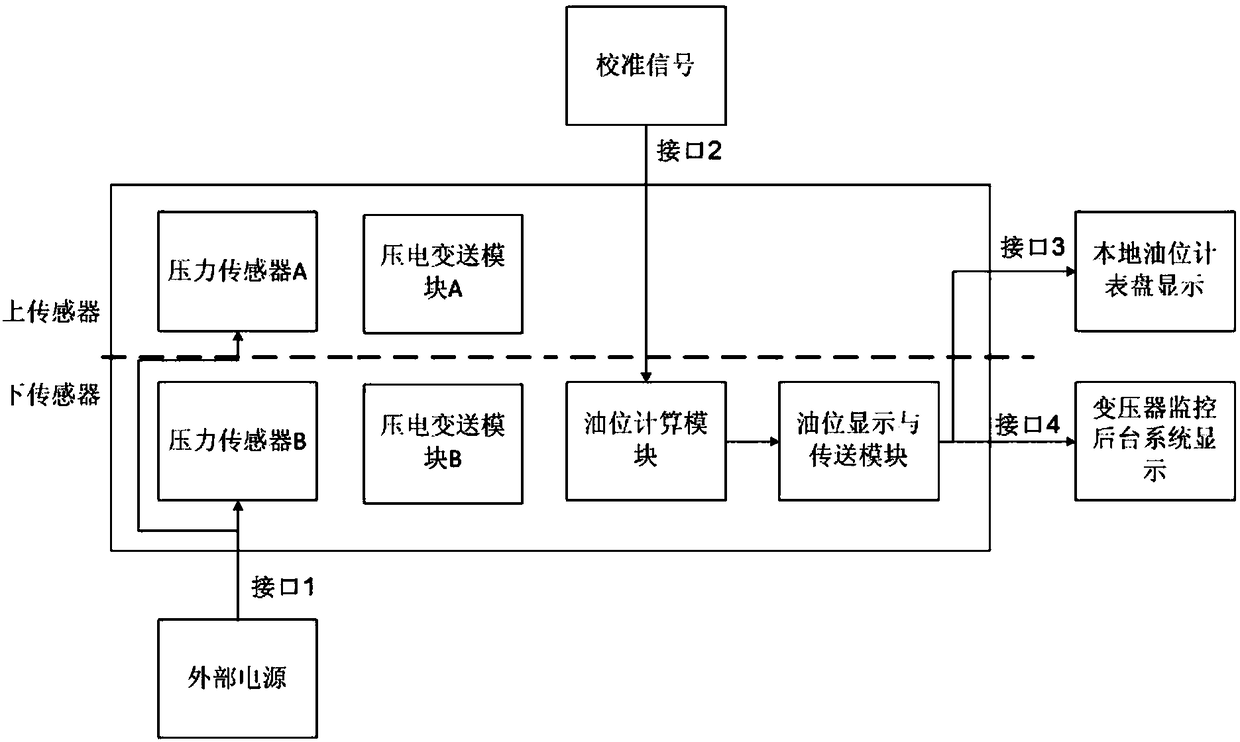

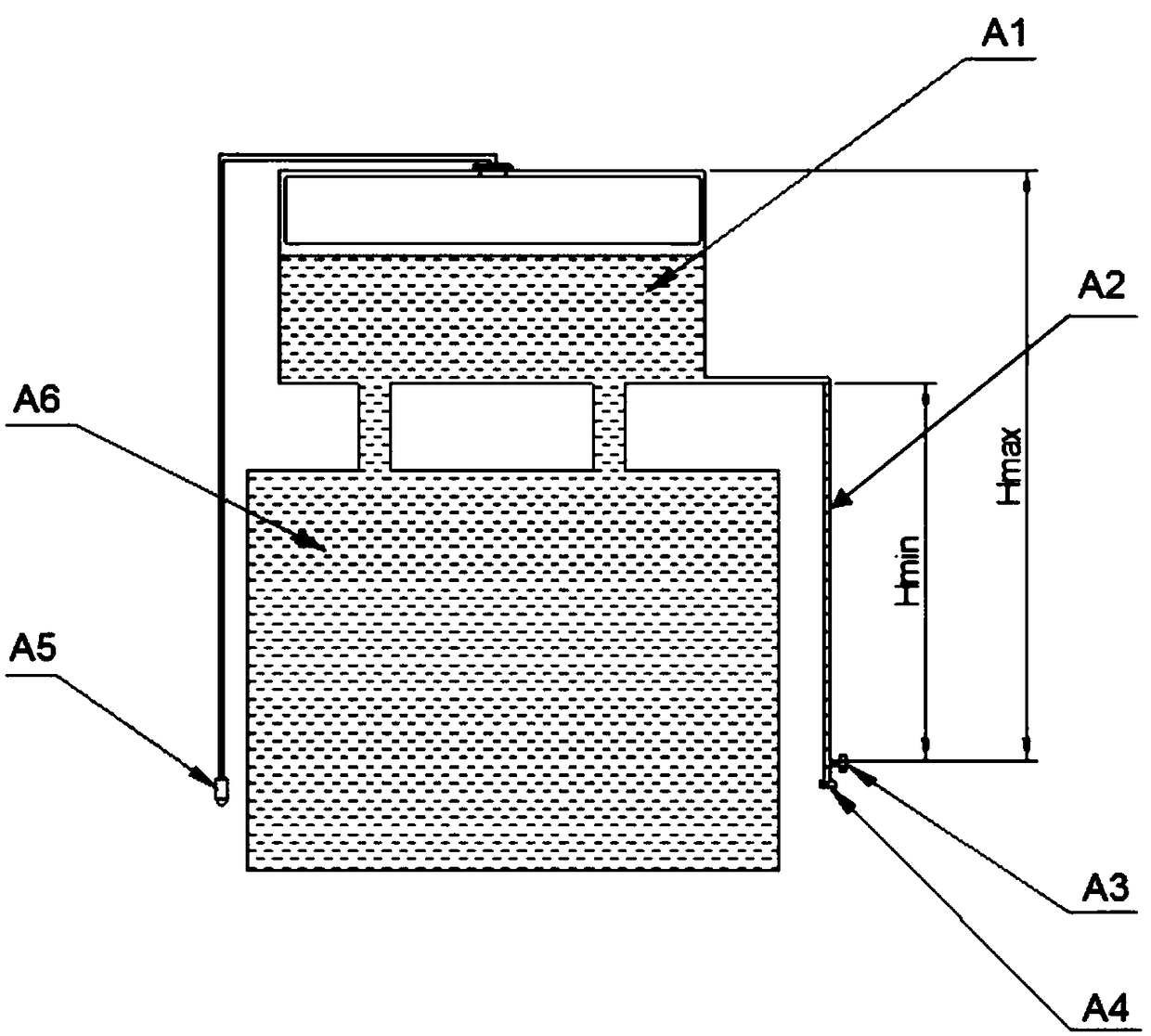

[0023] A dual pressure-sensitive correction type transformer oil level gauge, such as figure 1 As shown, it includes oil level gauge body 8, first oil level gauge body 2, second oil level gauge body 5, first pressure sensor 1, second pressure sensor 4, oil level gauge dial 3, butterfly valve 9, power supply and signal The cable 6 and the measuring circuit of the oil level gauge. The main body of the oil level gauge is a pipe with the same diameter as the oil filling and discharging pipe 11 of the transformer. Connect by other means. An oil discharge valve 7 is installed at the bottom of the oil discharge pipe. The first oil level gauge body and the second oil level gauge body are two sections of horizontal pipelines, and the two oil level gauge bodies are vertically arranged on the side wall of the oil level gauge body through respective butterfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com