Large-scale intelligent warehousing distributed sorting system

A smart storage and large-scale technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problem that the sensing range of sensors is easily affected by the environment, the increase in the calculation amount of the central control server, and the limitation of large-scale storage systems Deployment and other issues to achieve the effect of reducing the requirements for autonomous decision-making and computing capabilities of mobile robots, facilitating system deployment, and reducing deployment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

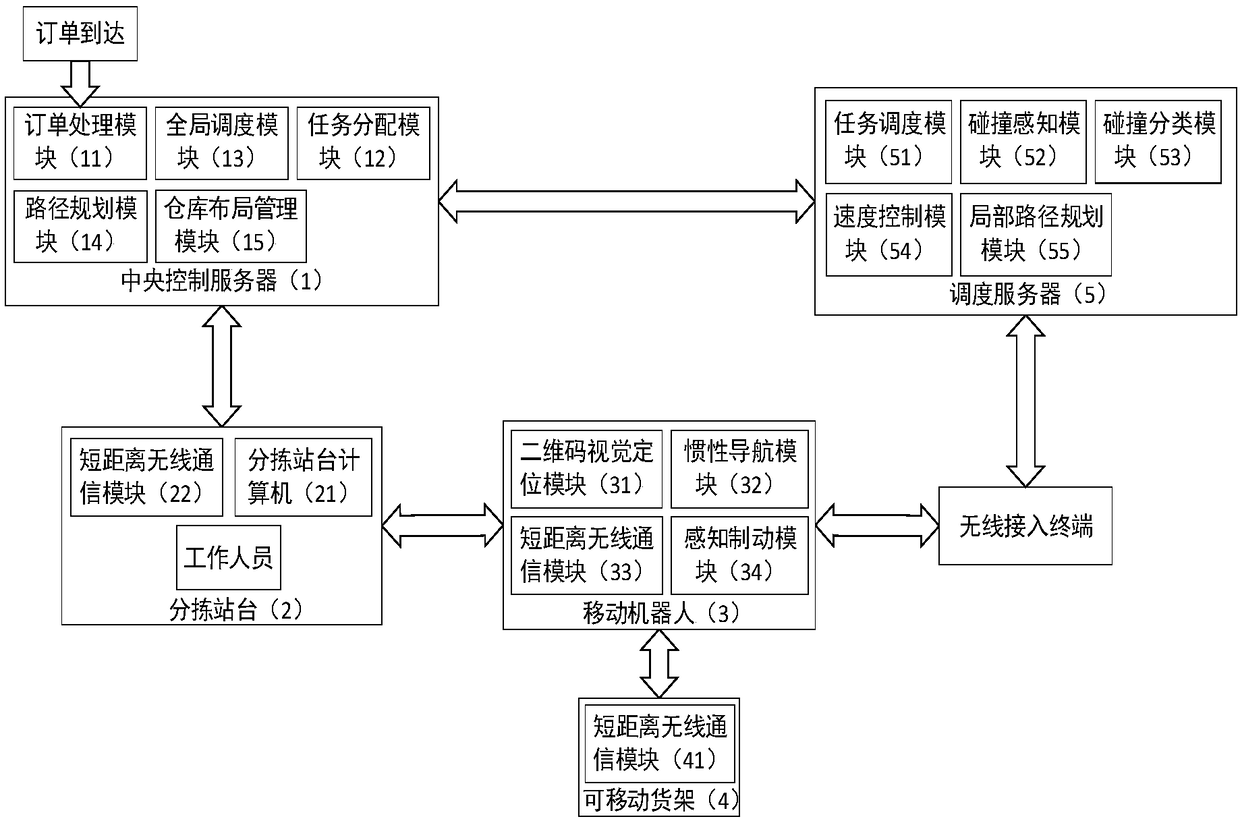

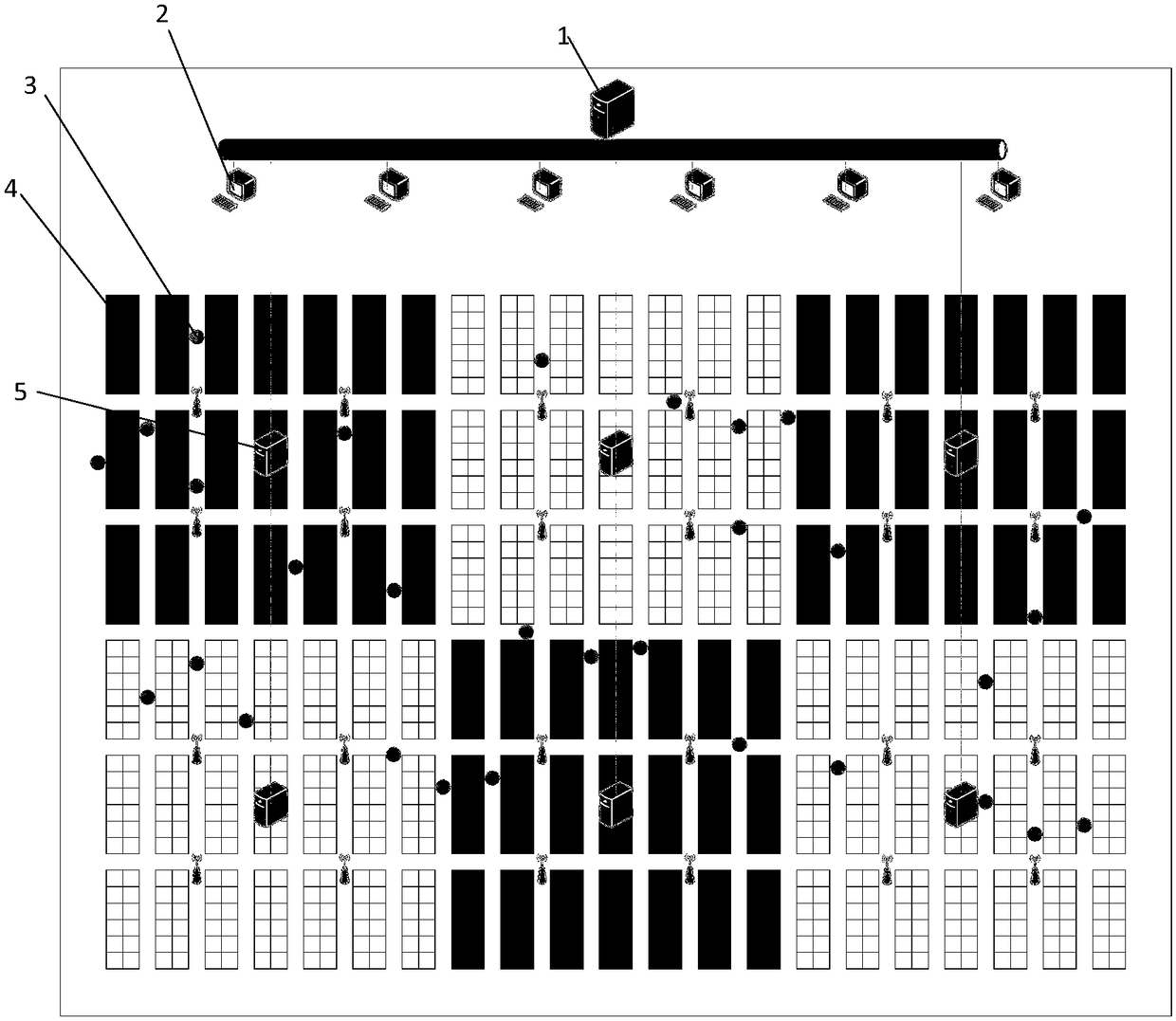

[0025] refer to figure 1 , the present invention includes a central control server 1, a plurality of scheduling servers 5, a plurality of sorting stations 2, a plurality of mobile robots 3 and a plurality of movable shelves 4. Wherein, the central control server 1 is respectively connected to each dispatching server 5 by wire, and each dispatching server 5 is wirelessly connected to a plurality of mobile robots 3 through a plurality of wireless access terminals, and each mobile robot 3 is respectively connected to a movable The rack 4 is wirelessly connected to a sorting platform 2, and each sorting platform 2 is wired to the central control server 1.

[0026] The central control server 1 includes: an order processing module 11 , a task assignment module 12 , a global scheduling module 13 , a path planning module 14 and a warehouse layout management module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com