Crumb chocolate flavor compositions

A composition, technology of chocolate, applied in the direction of food science, cocoa, confectionary industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0184] Example 1: Identification of major odor active compounds

[0185] This example identifies specific odor active compounds of milk chocolate by AEDA and SHO techniques.

[0186] Preparation of aroma isolates

[0187] Chocolate samples were deep-frozen with liquid nitrogen, ground to a fine powder with a laboratory grinder, and extracted sequentially with diethyl ether (DEE) for the times listed in the table below while stirring in the dark at room temperature. After the precipitate had settled, the supernatant was decanted and fresh DEE was added to the sediment. Stirring was started in the dark for the time indicated in the table below. In some cases, more than one decantation and continued extraction were performed. The supernatants from each sample were pooled for further evaluation.

[0188] Table 9. Volatile Compounds Extracted According to Analytical Method

[0189]

[0190] **: By HRGC-MS, TD-HRGC-ITD-MS, GCxGC-TOF-MS

[0191] Volatile compounds were separ...

Embodiment 2

[0232] Embodiment 2: Quantification of odorants

[0233] Quantification of the highly volatile compounds methylpropanal, 2-methylbutyraldehyde and 3-methylbutyraldehyde, 2,3-butanedione and Methyl mercaptan (see Example 1). deuterated and 13 C labeled internal standard and corresponding retention index. The data are summarized in Table 12.

[0234] Table 12. Concentrations of highly volatile compounds determined in DMGC and CGC

[0235]

[0236] CGC had higher concentrations in three of the five highly volatile compounds tested. Compared to DMGC, CGC has almost twice the amount of methyl mercaptan, almost three times the amount of methapropanal, and almost four times the amount of 2-methylbutyraldehyde. As for the other two highly volatile compounds, CGC and DMGC had comparable levels of 2,3-butanedione, while 3-methylbutyraldehyde was the highest for DMGC.

[0237] When comparing the purely quantitative data from CGC, clear differences in the concentrations of 2,3-bu...

Embodiment 3

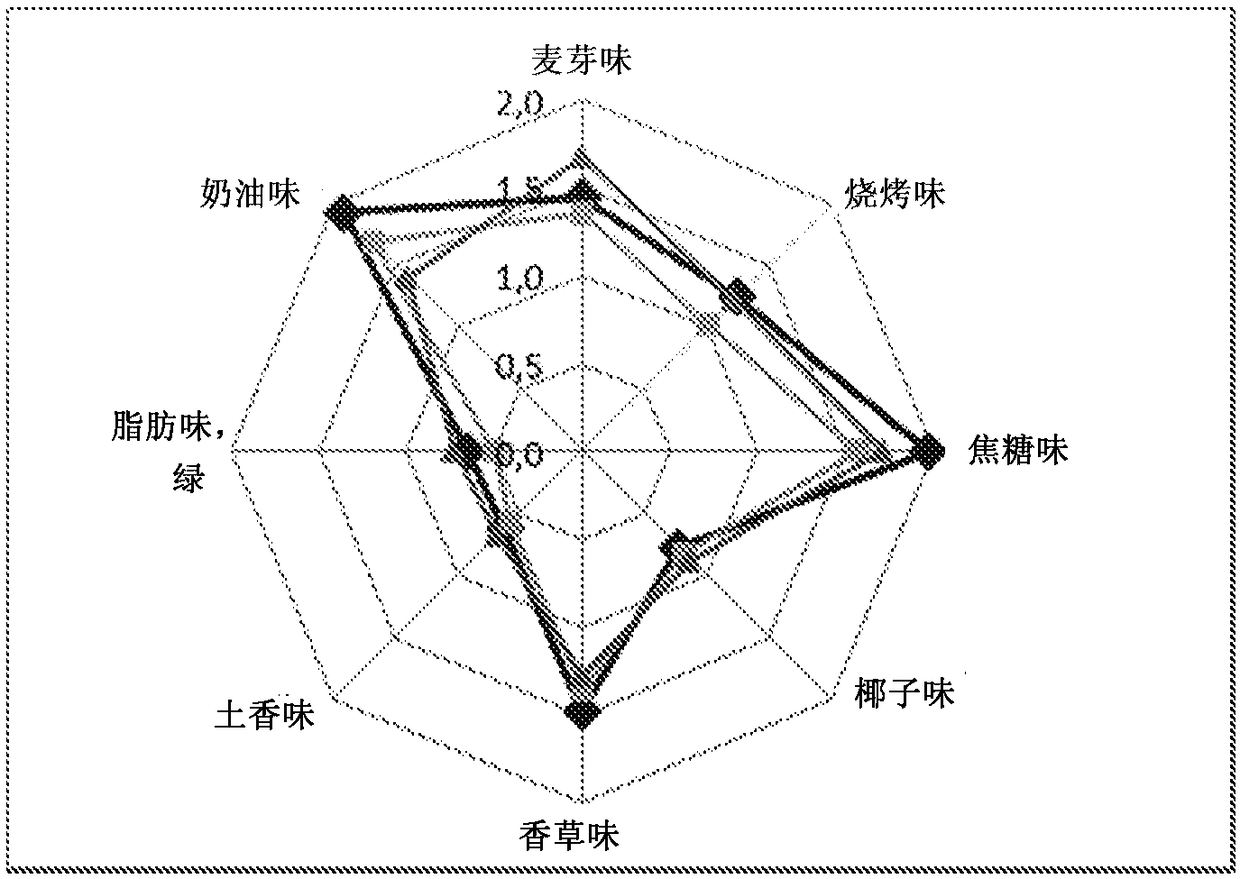

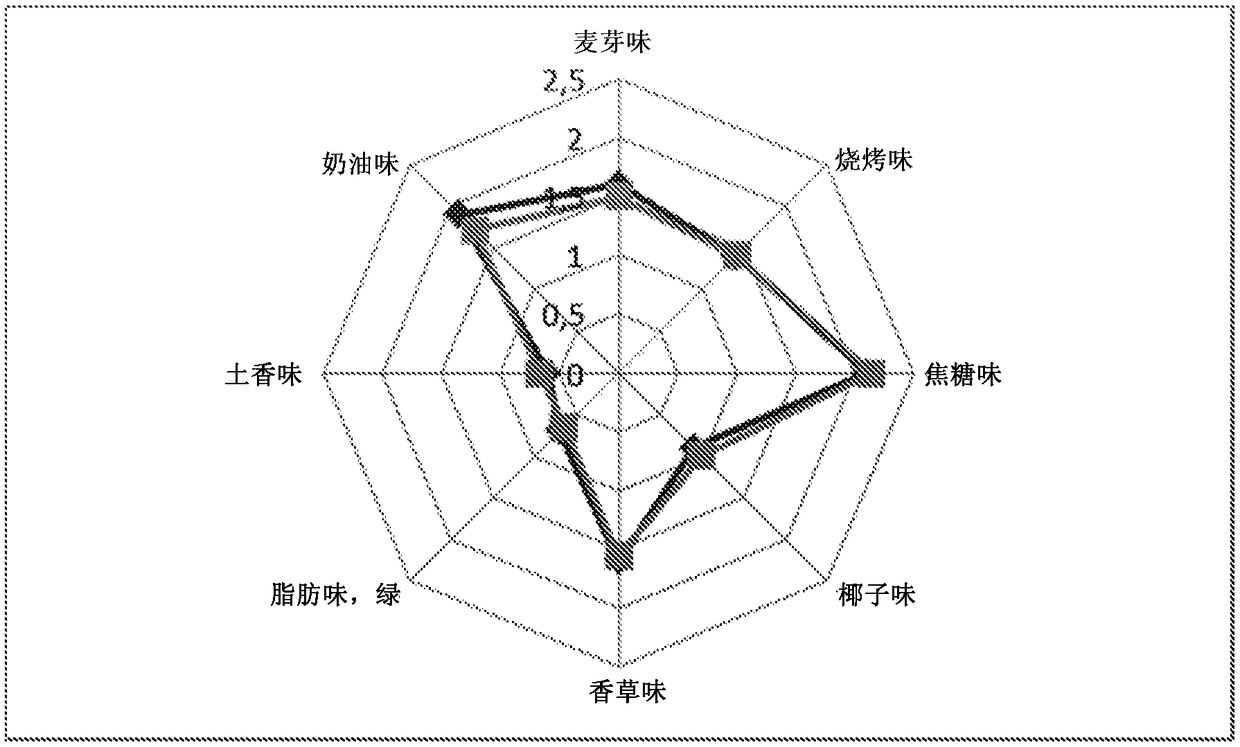

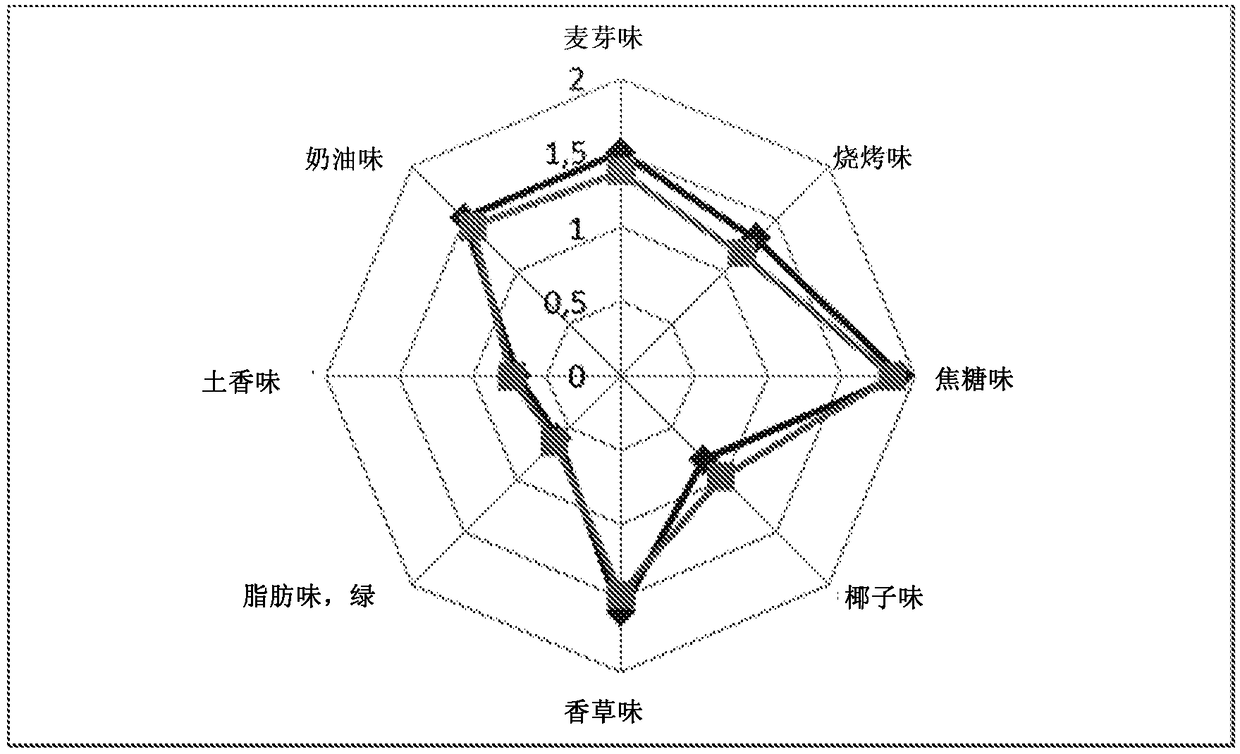

[0244] Example 3: Odor activity

[0245] Odor activity value (OAV) is a measure of the importance of a particular compound to the overall odor of a sample (eg chocolate). It is calculated as the ratio between the concentration of an individual substance in a sample and the threshold concentration (odor threshold, the minimum concentration that can be detected by the human nose) of that substance or:

[0246]

[0247] Therefore, odorants with an OAV greater than 1 generally contribute to the aroma of the corresponding food.

[0248] Determination of odor thresholds in model aroma matrices. Since crumb chocolate consists of about 30% fat, odor thresholding was performed in unflavored sunflower oil according to Czerny et al., European food research and technology 1993, 196(5), 417-422. Literature-based odor thresholds were used only if they were performed under the same conditions. Based on the determined odor threshold and quantitative experiments, the odor activity values...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com