Workplace Safety Systems for Auto Body Shops

A technology of safety system, maintenance workshop, applied in the field of workplace safety system, which can solve problems such as explosion, damage to the overall health status of employees, and employee hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

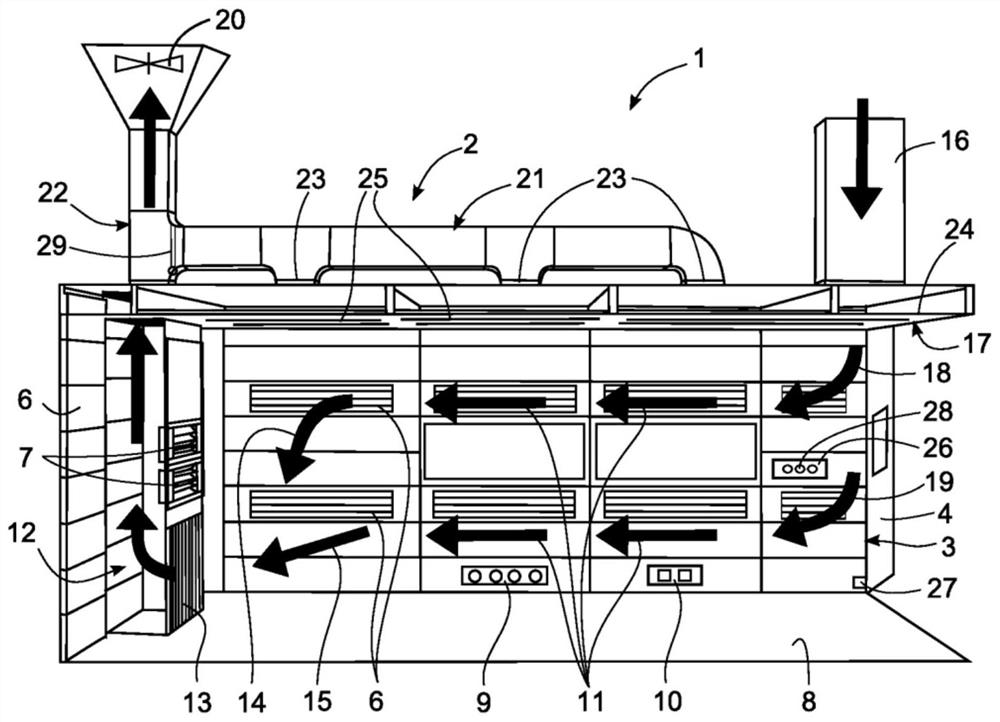

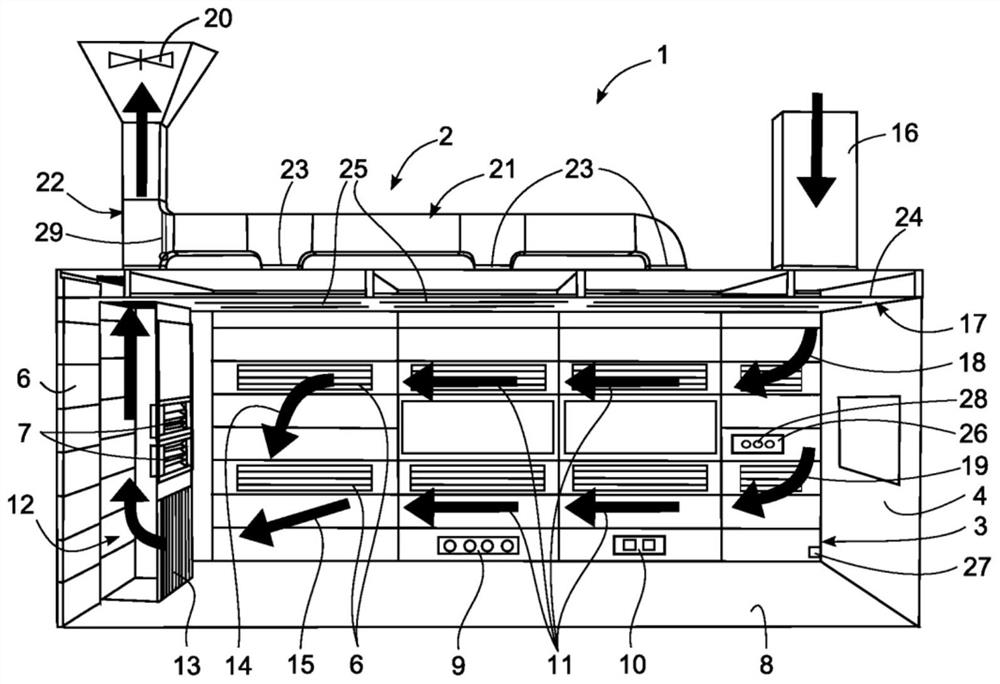

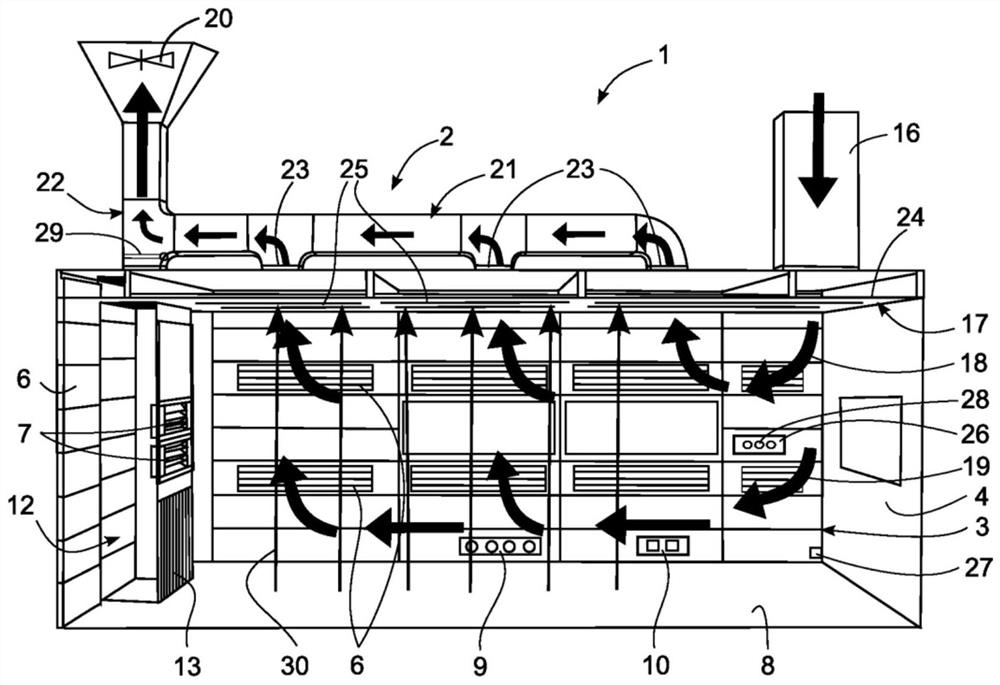

[0023] The present invention will now be described with reference to embodiments of the invention and with reference to the accompanying drawings. First refer to figure 1 , which shows a schematic diagram of a workshop safety system for an automobile body repair workshop, the workshop safety system comprising a workshop 1 having a ventilation system 2 for exhausting components including welding fumes, Contaminated air including paint soot and abrasive dust from grinding or sanding work performed on the bodywork (not shown). Such as figure 1 Shown in the open position in , the workshop 1 is provided with an entrance 3 arranged to be selectively closed or opened by means of a door 4 . The entrance 3 may alternatively be provided with a curtain (not shown).

[0024] Furthermore, the booth 1 is generally rectangular in shape and has soundproof side walls 5 and an end wall 6 positioned opposite the entrance 3 . The side walls 5 and the end walls 6 are provided with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com