Method of production using melting and hot isostatic pressing

A technology of additive manufacturing and powder layer, applied in the field of powder metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

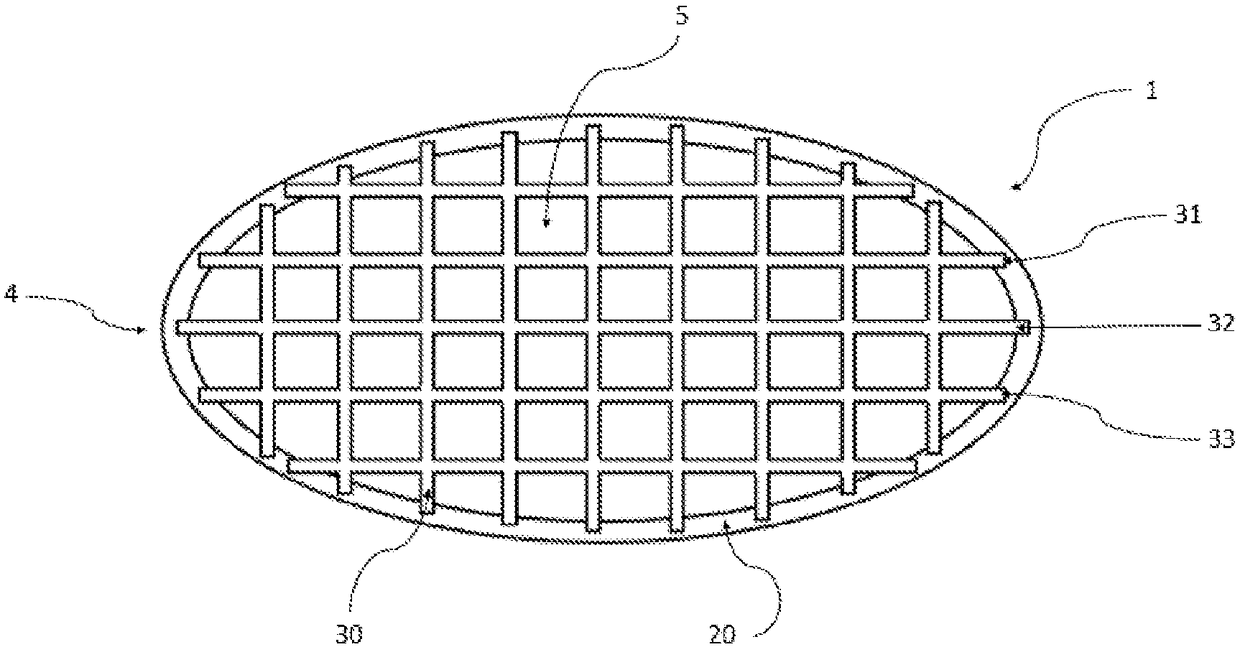

[0050] Such as figure 1 and figure 2 As shown, the invention relates to a method for producing a three-dimensional object 1 .

[0051] The manufacturing method according to the invention consists more precisely in forming a three-dimensional object 1 by stacking a plurality of thin layers 4 of powder (usually metal), said powder being able to be melted in some places of layers 4 by means of an energy source or energy beam.

[0052] Regarding the powder used in the method of the present invention, it is generally a metal powder comprising a single metal or a mixture or alloy of several metals.

[0053] However, this embodiment should not be seen as limiting, the powders used in the method of the invention may also, for example, comprise ceramic powders.

[0054]In a specific embodiment, "doped" powders are used in carrying out the various steps of the method, ie in which the preferably metallic particles are provided with nanoparticles.

[0055] With regard to the size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com