Rubber composition and tire

A technology of rubber composition and compound, which is applied in the direction of special tires, tire parts, tire tread/tread pattern, etc., can solve the problems of difficult tire ice performance, poor wear resistance, blending, etc., and achieve improvement Performance on ice, effect of good performance on ice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] Hereinafter, the present invention will be further described in detail by way of examples. The present invention is not limited to these examples in any way.

[0159]

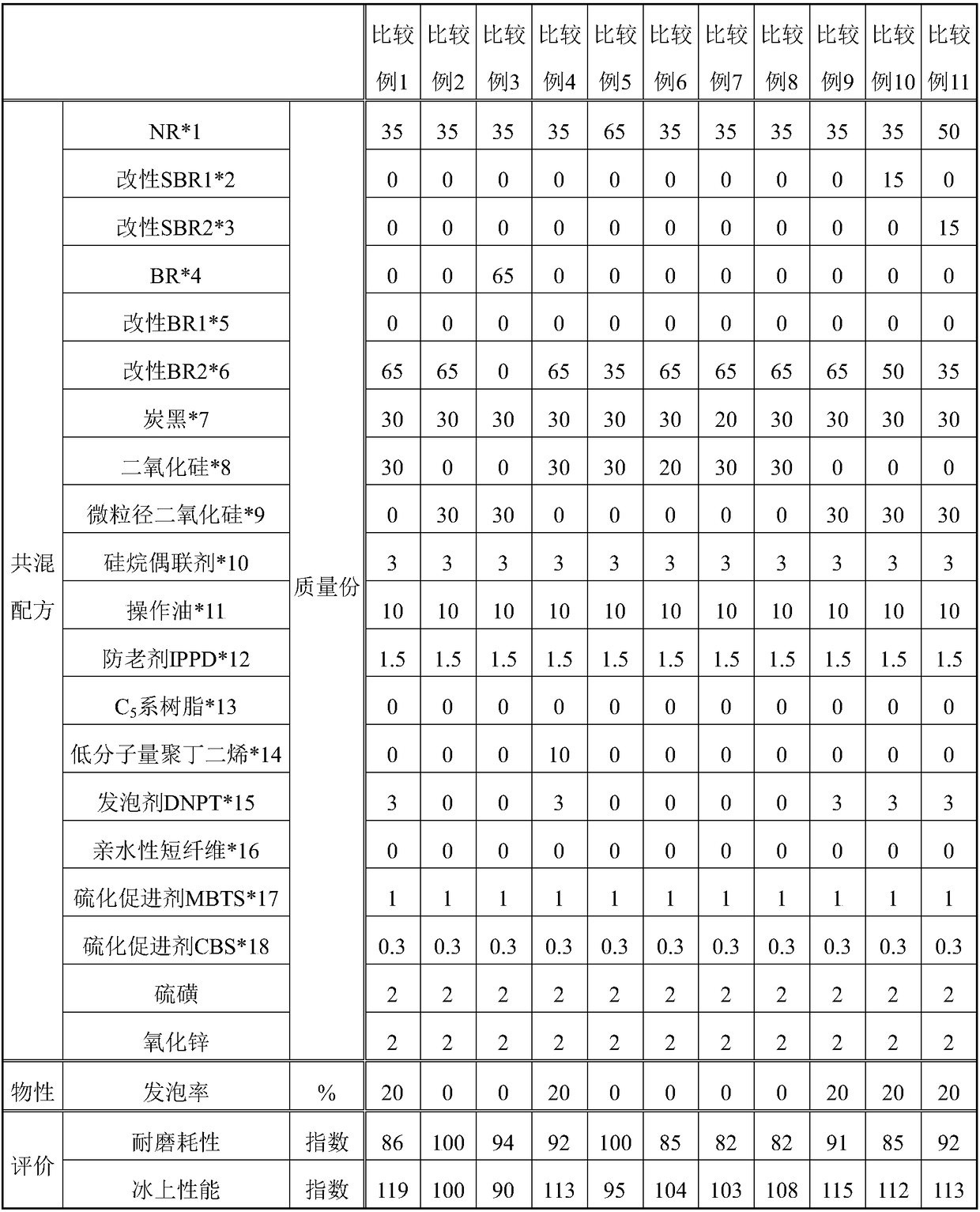

[0160] Rubber composition samples were prepared according to the blending formulations shown in Tables 1 and 2. According to the method described in paragraph [0009] of the present invention, the sample is observed by using a scanning probe microscope. The formation of a phase-separated structure and a plurality of polymer phases immiscible with each other was confirmed in each rubber composition sample.

[0161]

[0162] A test sample tire (tire size: 195 / 65R15) was prepared by using the rubber composition sample thus obtained in its tread according to a conventional method. The foaming ratio of the tread of each sample tire was calculated according to the above formula (ii). The wear resistance and on-ice performance of each sample tire were then evaluated by the methods described below. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com