Powder progressively-increasing pressing device and method

A powder and embryo pressing technology, applied in the field of material processing and mechanical equipment, can solve problems such as affecting product performance, uneven pressing embryo density, affecting production automation, productivity and production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

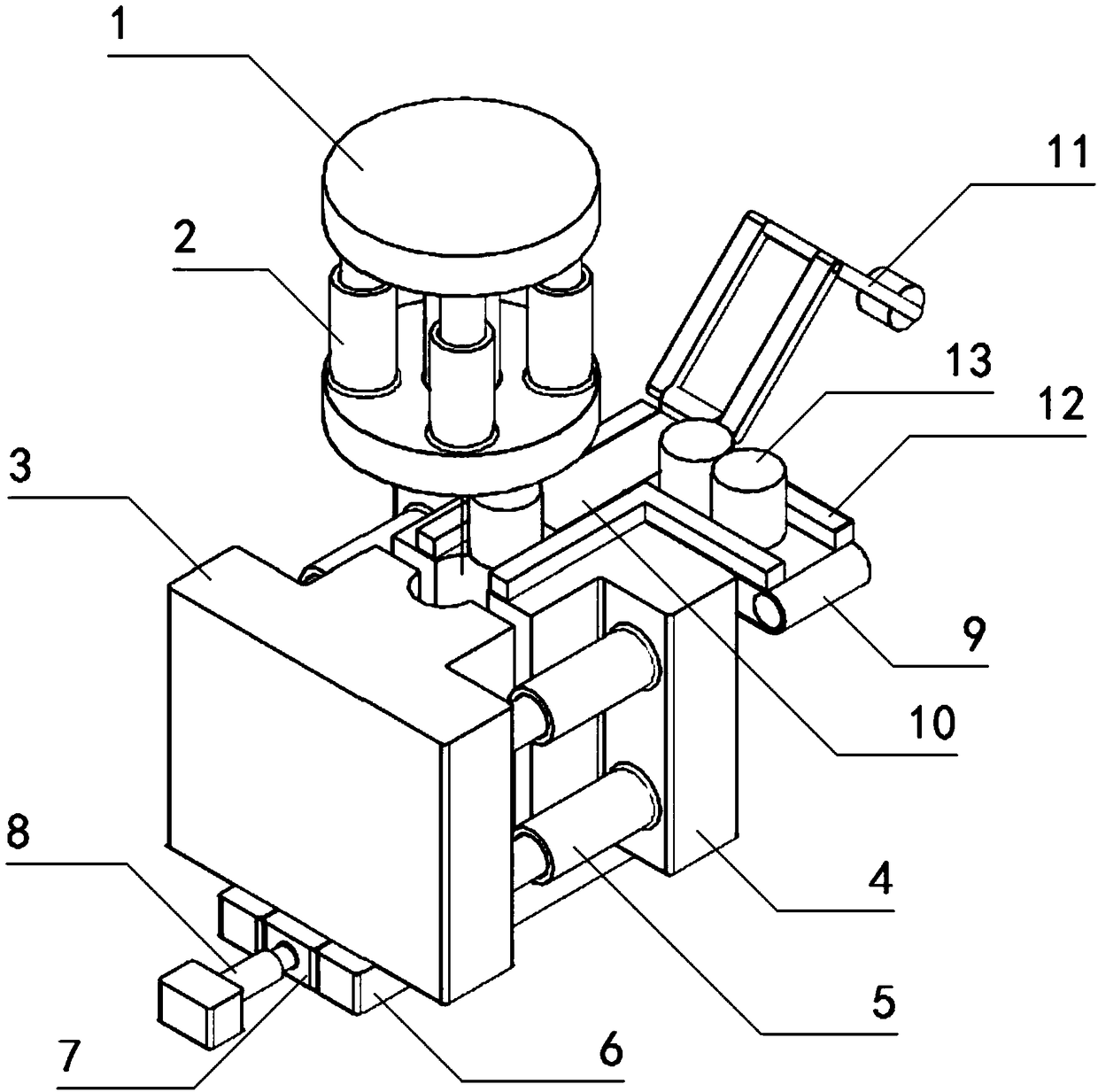

[0069] A powder incremental pressing device, such as image 3 , 4 , 5, including upper die punch 1, upper die punch hydraulic rod 2, front female die 3, rear female die 4, female die hydraulic rod 5, lower die punch 6, stripping plate 7, stripping plate hydraulic rod 8, conveyor belt 9. Push plate 10, push plate connecting rod 11, guide rail 12, conveyor belt servo motor 14, push plate connecting rod servo motor 15, female mold hydraulic rod servo motor 16, upper die punching hydraulic rod servo motor 17, ejector plate hydraulic rod servo Motor 18, automatic control circuit, the upper die punch 1 and the upper die punch hydraulic rod 2 are located directly above the front die 3 and the rear die 4, and the upper die punch 1 is realized by cooperating with four upper die punch hydraulic rods 2 Move along the axial direction of the upper die punch 1, and the axis of the upper die punch 1 coincides with the central axis after the front die 3 and the rear die 4 are closed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com