Auxiliary mechanism used for key groove forming of chain wheel with multiple sizes

A technology of auxiliary mechanism and sprocket, which is applied in metal processing equipment, accessories of broaching machine, broaching machine, etc., can solve the problems of lack of positioning device and inconvenience, and achieve the goal of improving synchronization effect, saving reserves, and improving positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

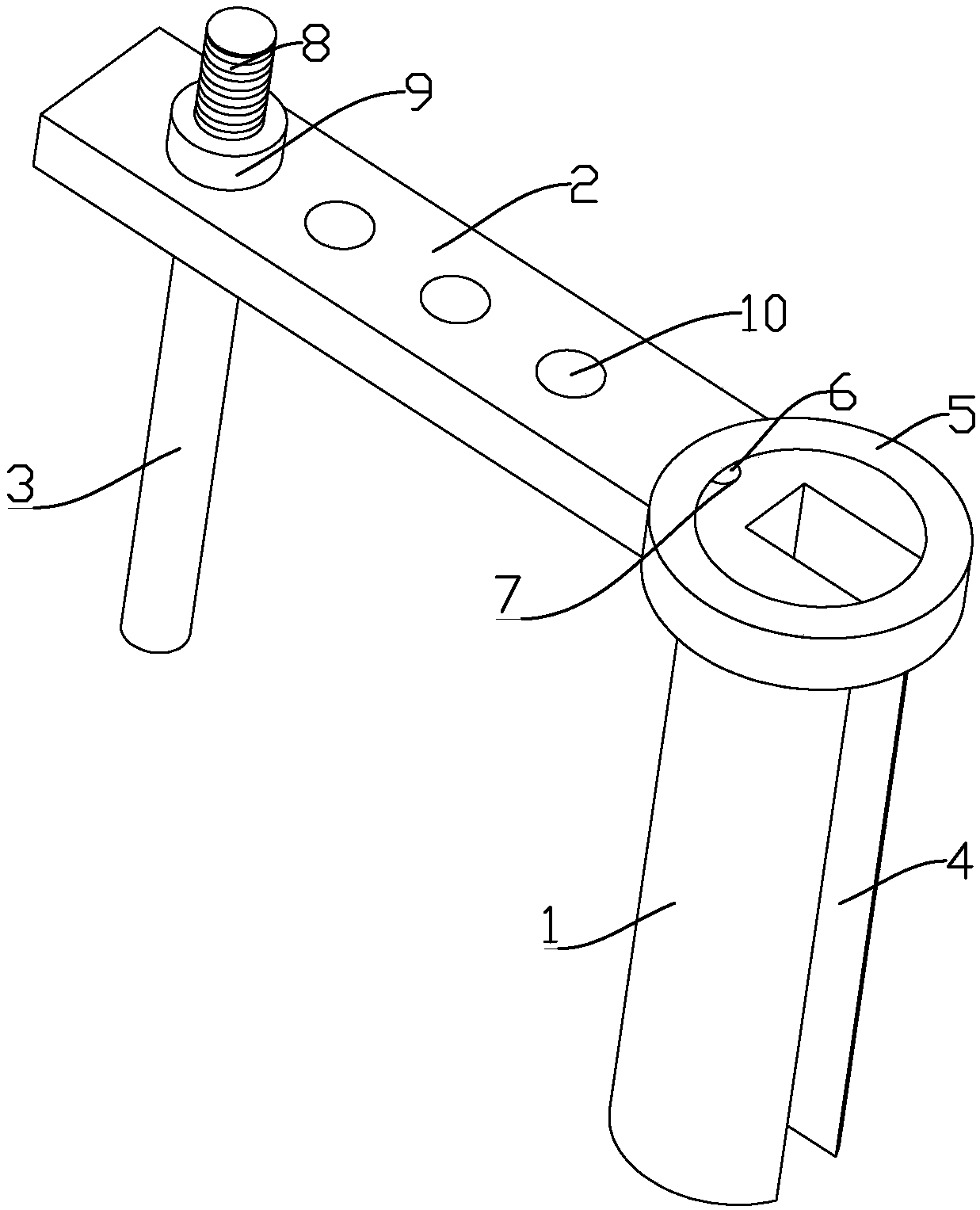

[0013] Such as figure 1 As shown, an auxiliary mechanism for opening keyways of sprockets of various sizes includes a central shaft 1, a positioning plate 2 and a positioning rod 3, and the central shaft 1 is provided with a keyway broach groove 4 in the axial direction. The keyway broach groove 4 of the keyway runs through the two ends of the central shaft 1, and one end of the positioning plate 2 is provided with a collar 5, and the collar 5 is clamped and fixed with one end of the central shaft 1, and the collar 5 is fixed on the positioning plate 2. One side of the collar 5 is fixed with a boss 6 that protrudes toward the center of the collar 5. The cross section of the boss 6 is semicircular. The groove 7, the groove 7 runs through the central axis 1 in the axial direction of the central axis 1, the positioning plate 2 is perpendicular to the central axis 1, and the positioning plate 2 is vertically away from the central axis 1 There are a plurality of through holes 10 v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com