Equivalent assessment method for structural corrosion inspection requirements based on aircraft service corrosion data

An aircraft structure and equivalent technology, applied in the direction of aircraft component testing, etc., can solve the problems of insufficient comprehensiveness, difficulty in obtaining the corrosion data of the joint surface of the aircraft structure connection part, long evaluation period, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

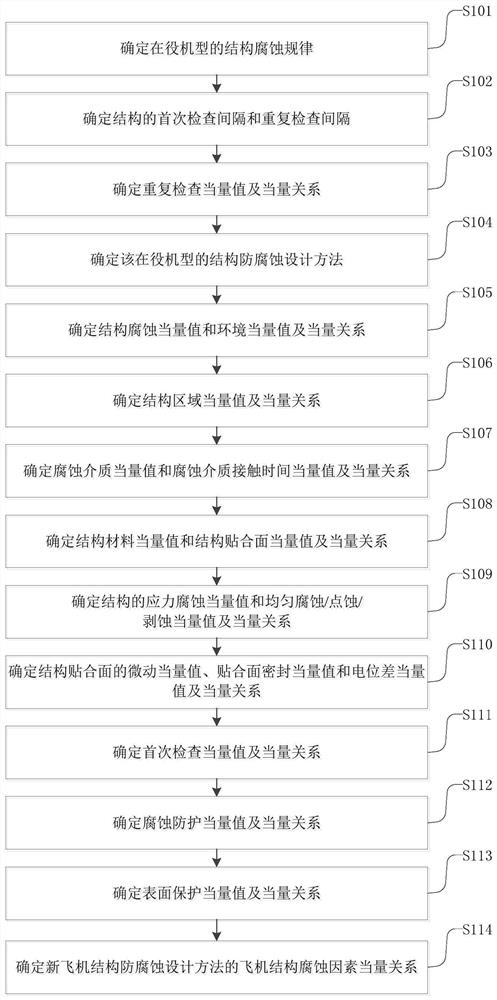

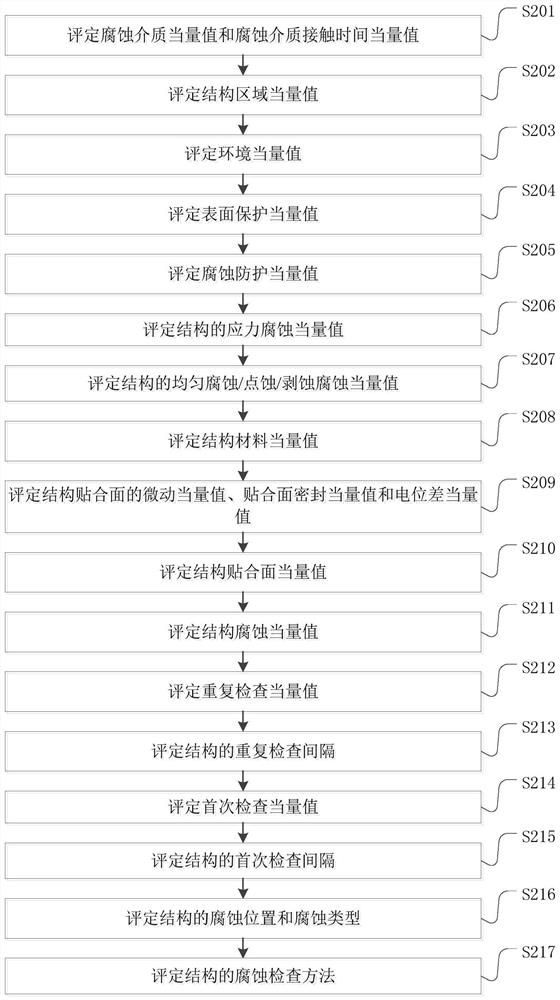

[0064] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustment.

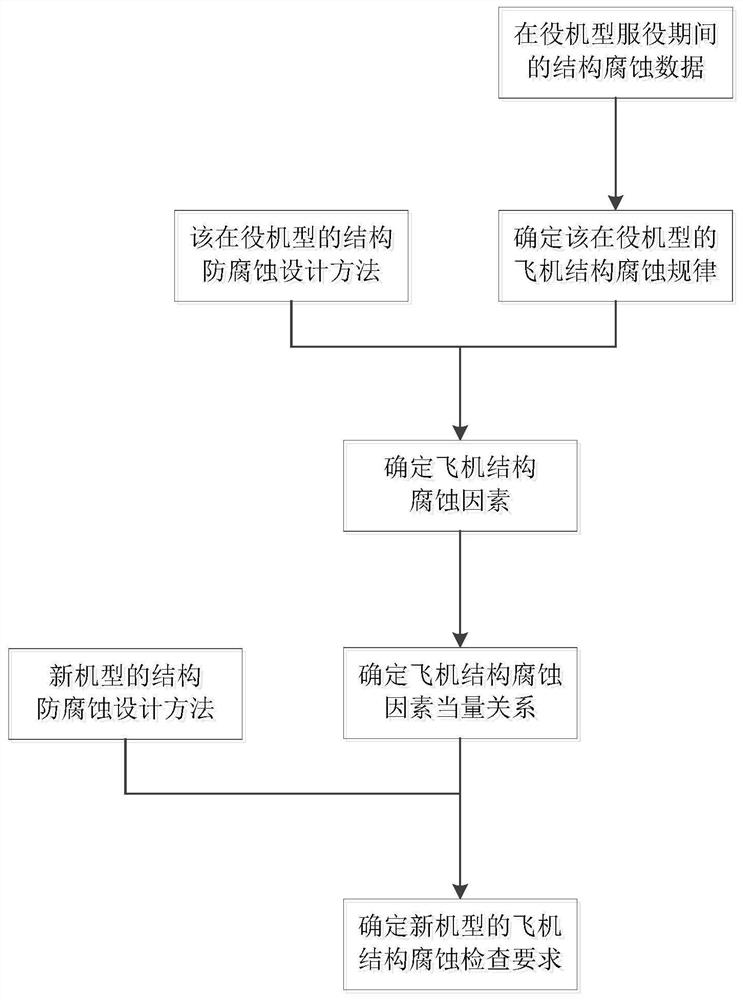

[0065] refer to figure 1 , an equivalent assessment method for structural corrosion inspection requirements based on aircraft service corrosion data, including the following steps:

[0066] According to the structural corrosion data of the in-service model during its service, determine the structural corrosion law of the in-service model;

[0067] According to the structural anti-corrosion design method and structural corrosion law of the in-service aircraft type, determine the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com