A composite bushing assembly used in the teaching of power transmission high-voltage cable joints

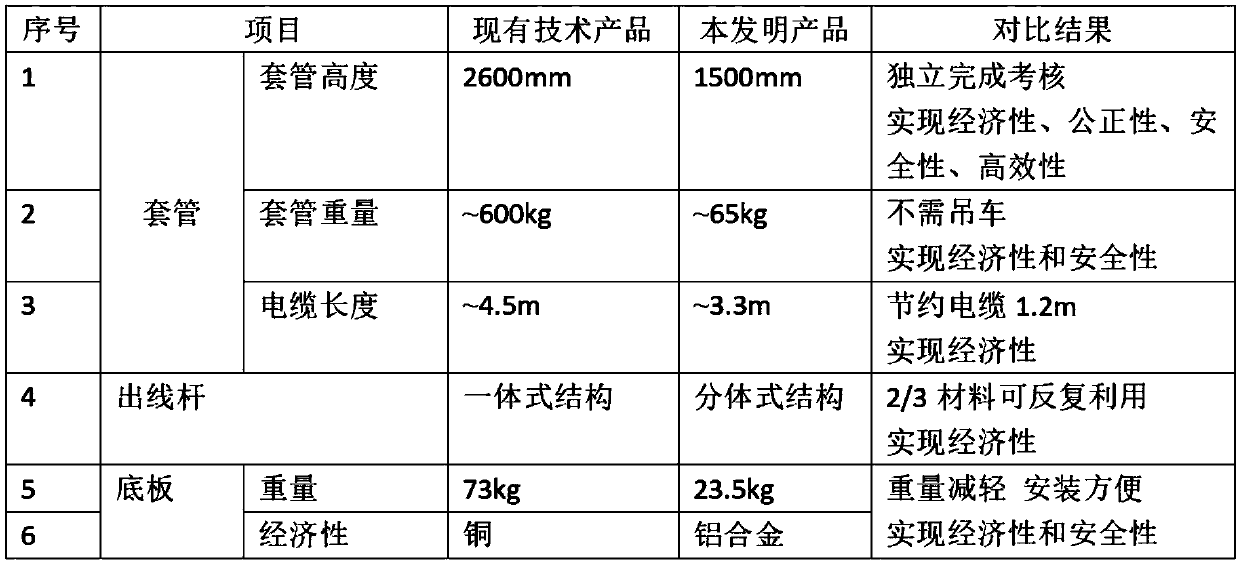

A composite bushing and high-voltage cable technology, which is applied to teaching models, educational tools, instruments, etc., can solve the problems of increased training costs, heavy weight and high height of bushing components, and achieve improved assessment safety, reduced processing time, and reduced The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

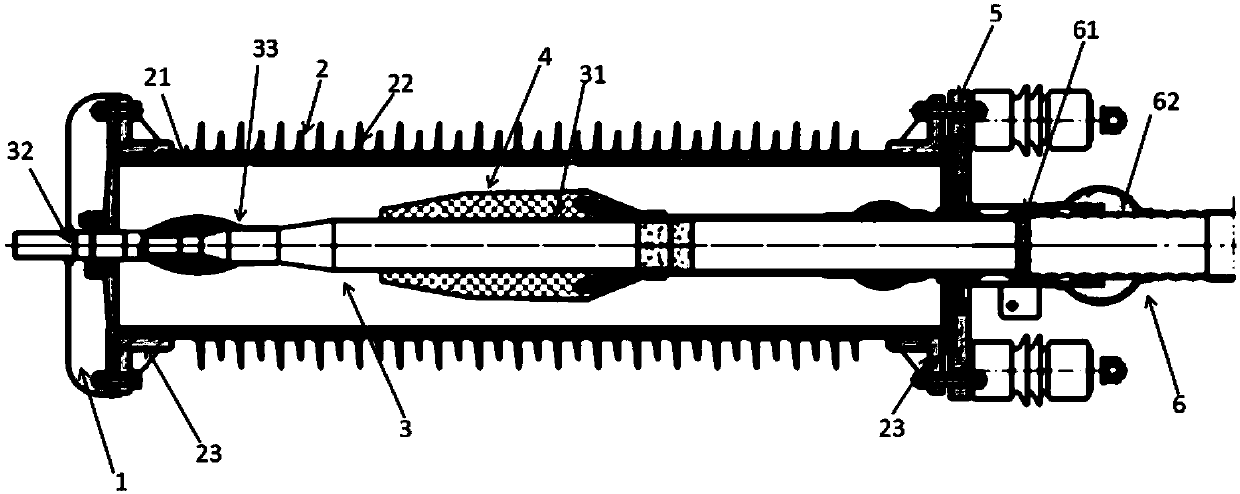

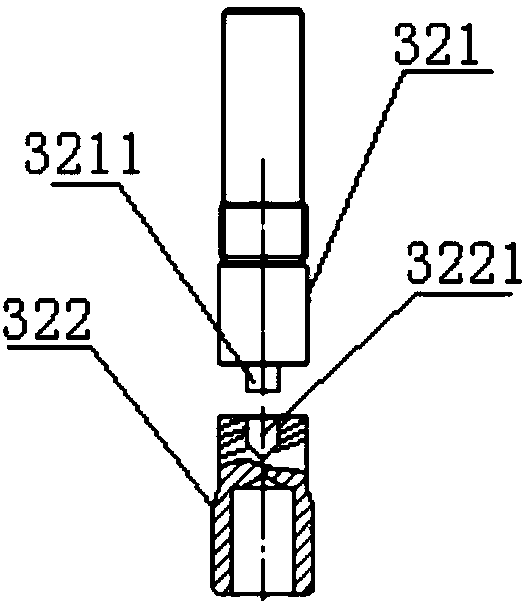

[0038] Such as figure 1 As shown, a composite bushing assembly used for teaching high-voltage cable joints for power transmission, the composite bushing 2 assembly includes: top cover 1, composite bushing 2, cable assembly 3, stress cone 4, bottom plate 5 and tail pipe assembly 6 .

[0039] Among them, the top of the composite casing 2 is connected to the top cover 1; the cable assembly 3 is arranged in the composite casing 2; the stress cone 4 is arranged in the composite casing 2 and placed on the cable assembly 3; the bottom plate 5 is arranged in the composite casing 2 bottom, and connected with the composite casing 2; the tail pipe assembly 6 is set on the bottom plate 5, and communicated with the cable assembly 3.

[0040] Such as figure 1 As shown, the composite sleeve 2 includes: a sleeve 21 and a sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com