Clean type hydrogen-enriched cup

A hydrogen-rich water cup, clean technology, applied in drinking water vessels, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as cumbersome operation, easy to get dirty, and affect the service life of hydrogen-rich water cups The effect of friction resistance, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

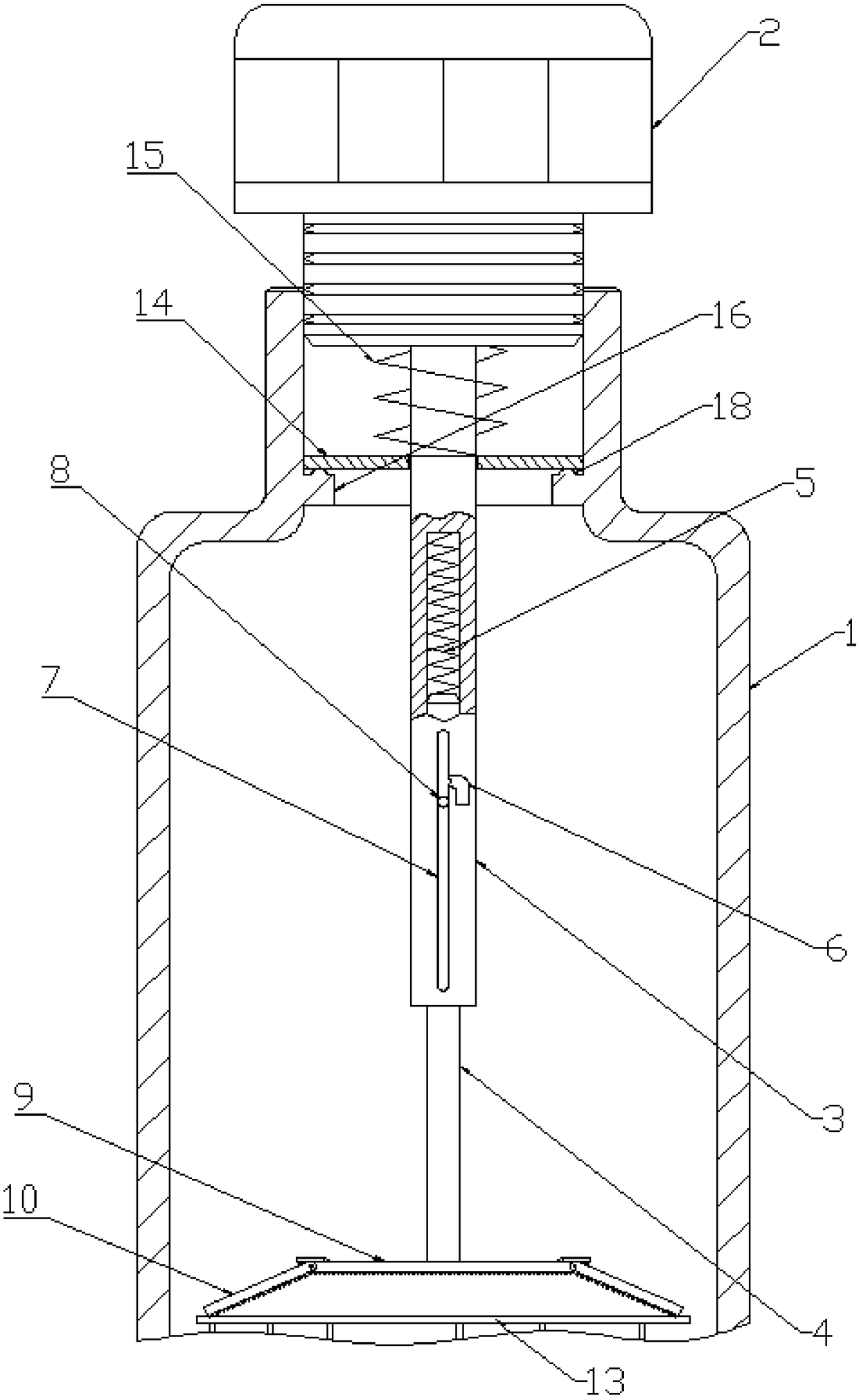

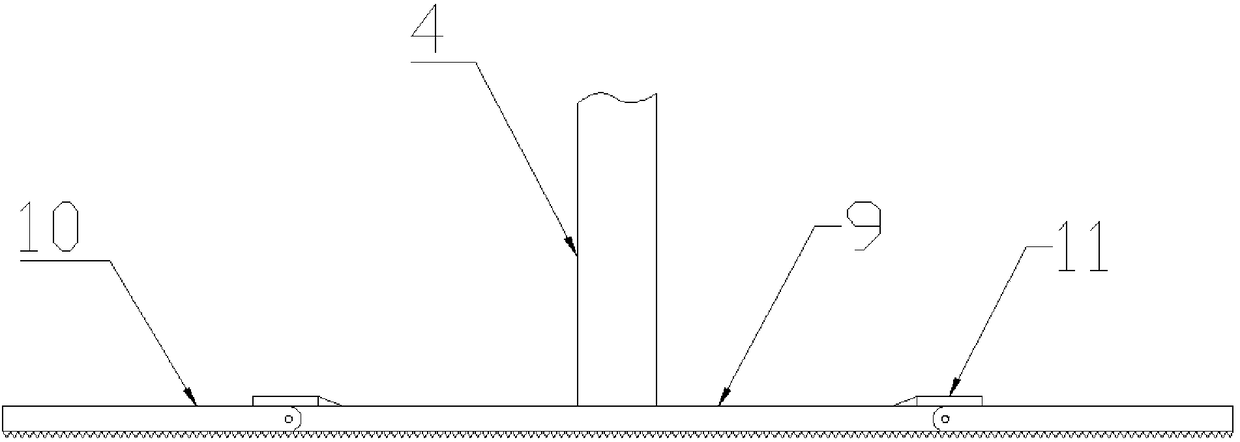

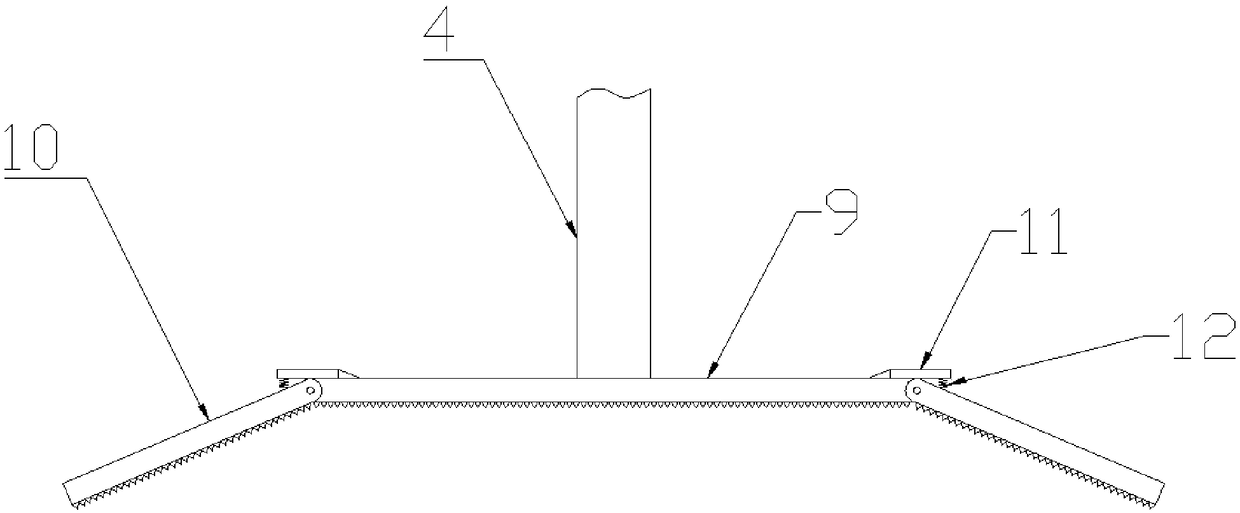

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a clean hydrogen-rich water cup, which includes a cup body 1 and a cup cover 2 threadedly connected to the end of the cup body 1. The cup cover 2 is covered with a sealing ring, and the cup cover 2 is relatively After tightening, the sealing of the cup body 1 is realized. The cup body 1 is in a normal use state. The bottom of the cup body 1 is equipped with an electrode plate 13. The cross sections of the cup body 1 and the cup cover 2 are all circular, and the cup body 2 A sleeve 3 is provided at the end of the sleeve 3, and a scraping rod 4 is slidingly arranged in the sleeve 3. The scraping rod 4 can slide freely along the axis direction of the sleeve 3, and there is a reset between the scraping rod 4 and the bottom of the sleeve 3. The spring 5 and the return sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com