A kind of preparation method of composite insulation material

A thermal insulation material, hydrogel technology, applied in the direction of coating, etc., can solve the problems of easy combustion, low porosity, fragile texture, etc., and achieve the effect of low thermal conductivity and low density thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Aiming at the shortcomings of organic heat insulation materials and inorganic heat insulation materials in the prior art, this application provides a preparation method of a composite heat insulation material. During the preparation process, the composite heat insulation material is made of organic hydrogel or organic Silica hydrogel is used as a raw material, and the skeleton of the hydrogel is further strengthened by the in-situ hydrolysis reaction of the silane coupling agent, resulting in a composite airgel with high strength, low density and low thermal conductivity. Specifically, the embodiment of the present invention discloses a preparation method of the composite thermal insulation material, including the following steps:

[0023] A) immersing the hydrogel in the catalyst solution for exchange to obtain an initial solution; the hydrogel is selected from one or both of organic matter hydrogels and organic matter / silicon dioxide composite hydrogels;

[0024] B) T...

Embodiment 1

[0036] A) immerse the bacterial cellulose / silica hydrogel in 0.5mol / L ammonia solution for 24 hours and then take it out for use;

[0037] B) Prepare 200mL of 80% ethanol solution of tetraethoxysilane, immerse the bacterial cellulose / silica hydrogel obtained in step A) into it, shake at 32°C and 160rmp for 24h, until the hydrogel is completely solidified ,take out;

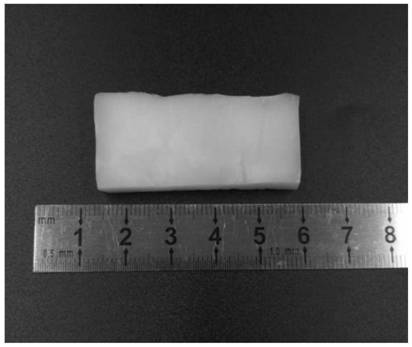

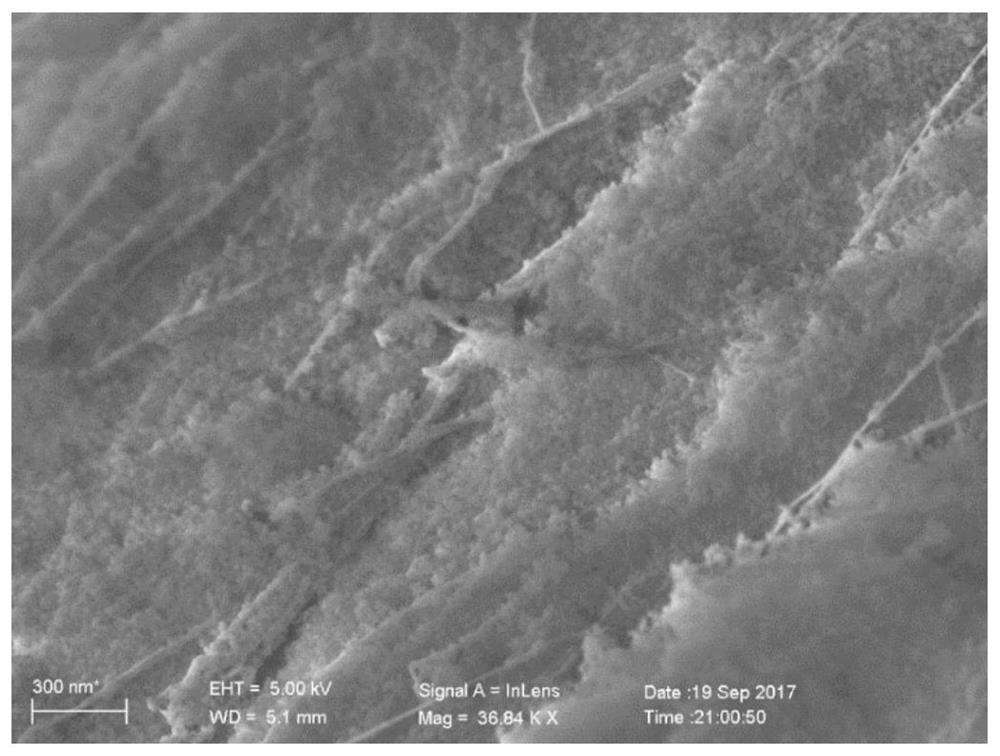

[0038] C) Rinse the composite obtained in step B) with 10 mL of n-hexane, then soak it in 200 mL of n-hexane for 24 hours, take it out and dry it at 70° C. to obtain the composite airgel. Such as figure 1 as shown, figure 1 For the photo of the composite airgel prepared in this embodiment, figure 2 It is the surface microscopic photo of the composite material airgel prepared in this embodiment 1. After calculation, it can be known that the density of the composite material airgel prepared in this embodiment is 0.15 g cm -3 .

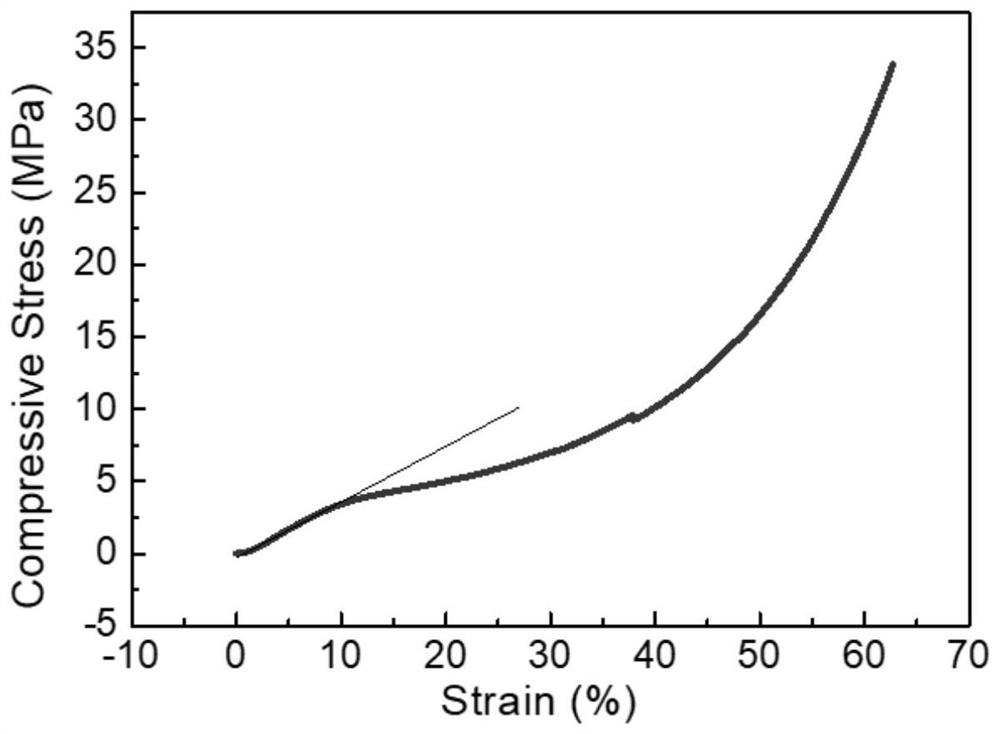

[0039] Test the mechanical properties of the composite airgel prepared in this emb...

Embodiment 2

[0041] A) Soak the agar hydrogel with a solid content of 1% in 0.5mol / L ammonia solution for 24 hours and then take it out for use;

[0042] B) Prepare 300mL of 80% methyltriethoxysilane hexane solution, immerse the gel obtained in step A) into it, shake at 32°C and 160rmp for 24h, until the hydrogel is completely hardened, take it out;

[0043] C) Rinse the composite obtained in step B) with 20 mL of n-hexane, then soak in 200 mL of n-hexane for 24 hours, take it out and dry it at 80° C. to obtain the composite airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com