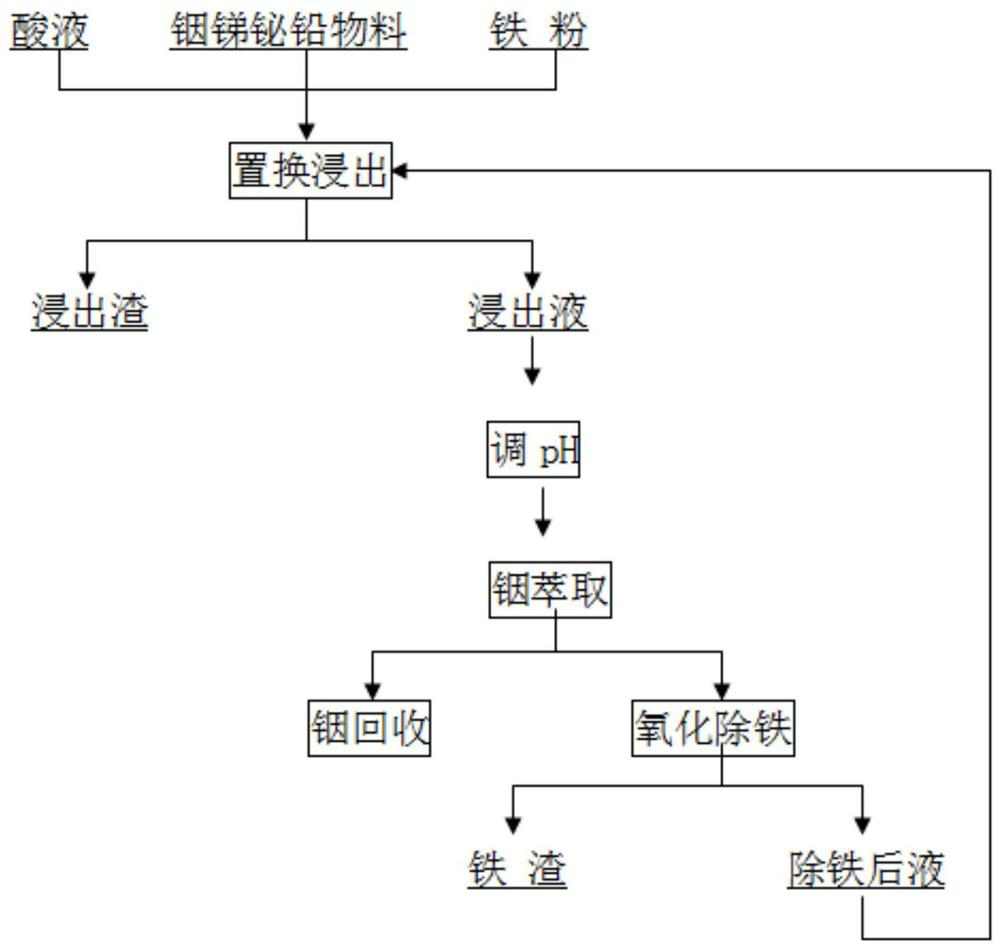

A method for improving the indium leaching rate of indium-antimony-lead material

A technology containing indium, antimony and lead, and leaching rate, which is applied in the field of metallurgy, can solve the problems of difficult leaching of indium, large amount of waste water, waste of scattered metal indium, etc., and achieve the effect of increasing economic value, increasing leaching rate, and efficient selective leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] According to the process steps, take 100g of indium antimony lead slag (in terms of chemical element mass percentage: Sb43.62%, In 6.32%, Pb 6.26%), add 30g / L hydrochloric acid+100g / L Cl - Add 40g of iron powder to 800mL of acid solution at a temperature of 80°C, and mechanically stir for 3h to obtain leaching residue and leaching solution. The hydrochloric acid at the leaching end point is 20g / L, the leaching slag contains 0.02wt% indium, 66.8wt% lead + antimony, and the leaching rate of indium is 99.72%. The antimony-lead slag is a good raw material for antimony recovery.

Embodiment 2

[0047] According to the process steps, take 200g indium antimony lead slag (in terms of chemical element mass percentage: Sb43.62%, In 6.32%, Pb 6.26%), add 40g / L hydrochloric acid+120g / L Cl -Add 100 g of iron powder to 1800 mL of acid solution at a temperature of 70 ° C, and mechanically stir for 4 hours to obtain leaching residue and leaching liquid. The hydrochloric acid at the leaching end point is 26g / L, the slag contains 0.026wt% indium, 60.8wt% lead + antimony, and the leaching rate of indium is 99.32%.

[0048] Adjust the pH value of the leach solution to 2, use the extractant p204 (concentration 30%) to perform four-stage extraction of indium, the extraction rate of indium reaches 99%, separate the indium and the extracted liquid, and recover the extracted indium;

[0049] Adjusting the pH value of the extracted liquid to 5, introducing oxygen to remove iron to obtain iron slag and iron-removed liquid, the iron-removed liquid is returned to the above-mentioned acid so...

Embodiment 3

[0051] According to the process steps, in industrial production, 30g / L hydrochloric acid + 100g / L Cl - acid solution 8m 3 , add 1000kg indium antimony lead slag (in terms of chemical element mass percentage: Sb 43.62%, In 6.32%, Pb 6.26%), heat up to 60°C, stir for 0.5h, start adding iron powder, add 4 times in batches every 0.5h, Add 80kg of iron powder each time, a total of 320kg of iron powder is added, take the liquid to test for lead+antimony<1g / L, indium is 7.7g / L, the slag contains 0.036wt% indium, the leaching rate of indium is greater than 99%, and the leaching rate of lead+antimony is less than 0.2wt%, to achieve the effect of efficient and selective leaching of indium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com