Integrated hat and knitting technology thereof

A top hat, integrated technology, applied in weft knitting, hats, knitting and other directions, can solve the problems of high production cost, low production efficiency, unstable hat quality, etc., and achieve low production cost, high production efficiency, and convenient large-scale batches. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

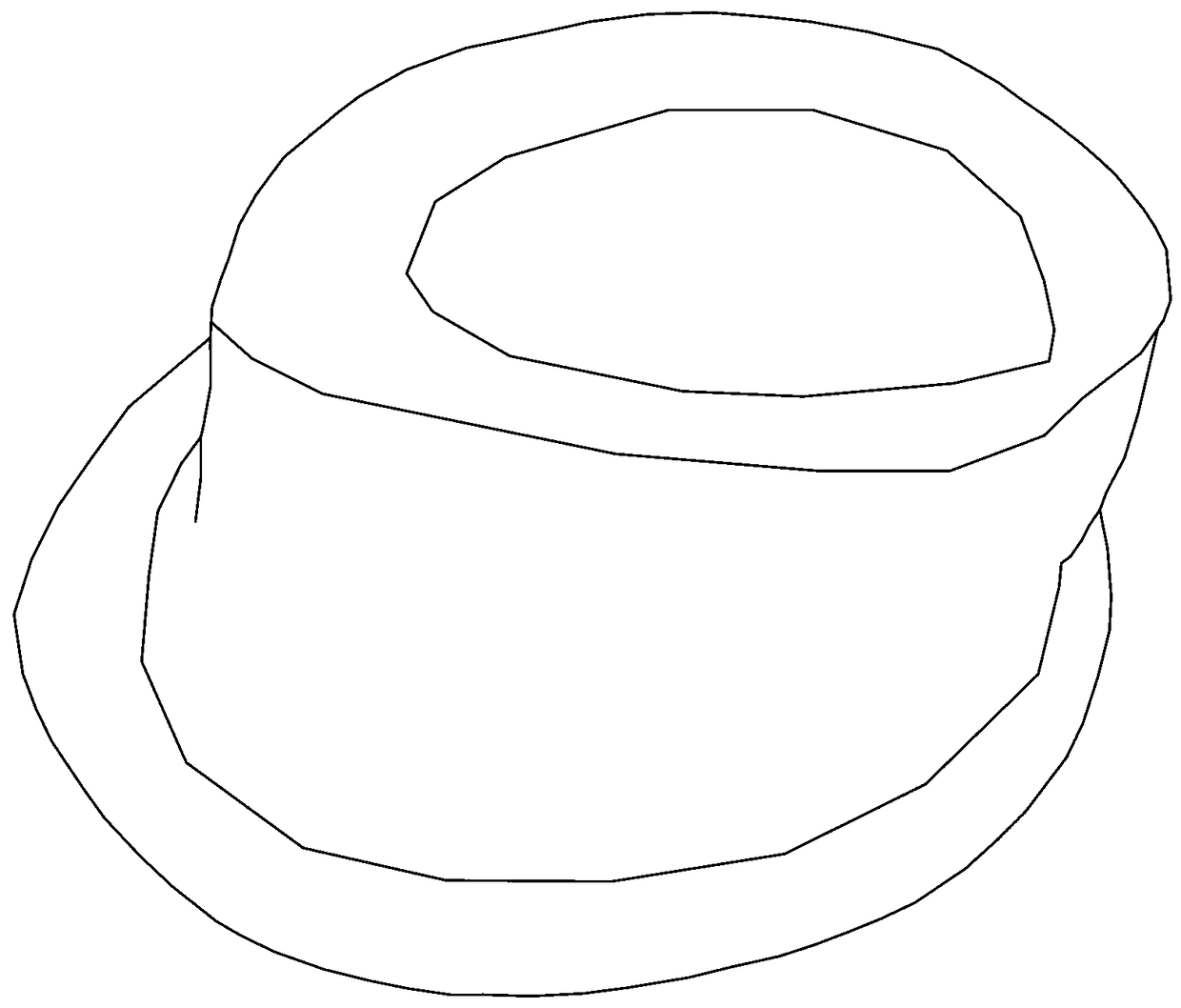

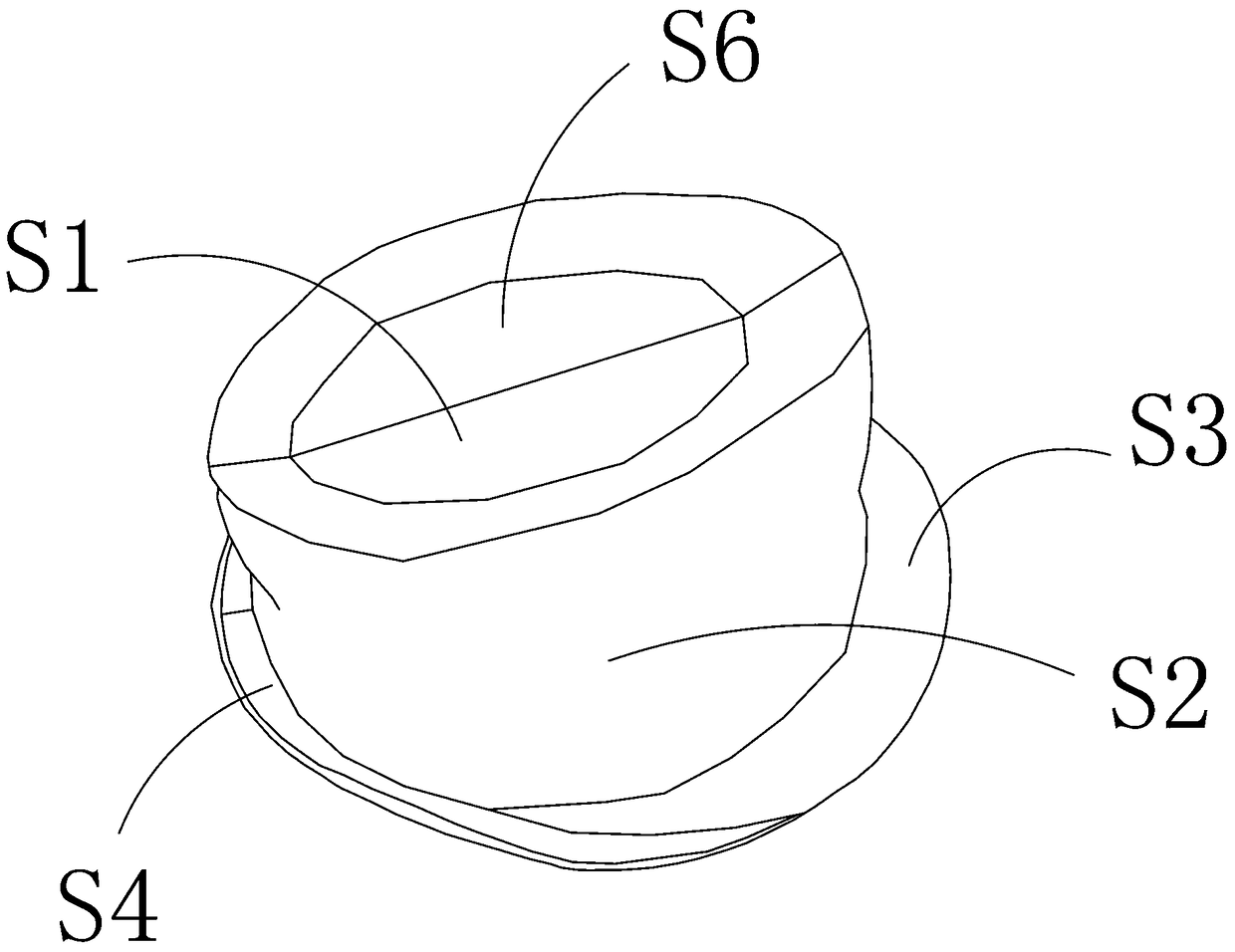

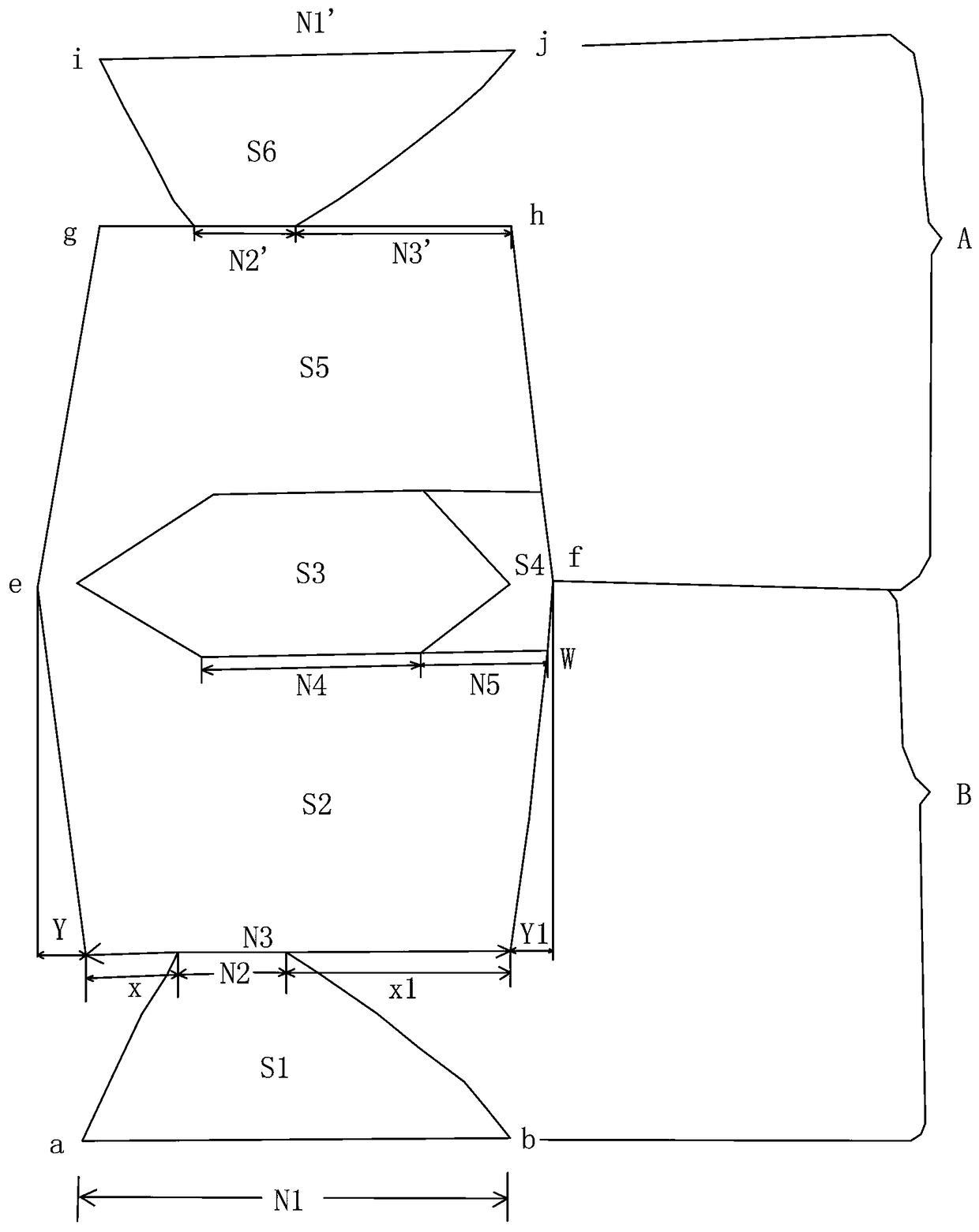

[0022] Such as Figure 1 to Figure 4 Shown, a kind of knitting process of one-piece top hat comprises the following steps:

[0023] (1) Knitting preparation, computerized flat knitting machine for weft knitting with one needle bed at the front and back, at least one of the needle beds of the computerized weft knitting machine can move left and right, and the needle bed has the function of transferring stitches , weft knitting computerized flat knitting machine with two or more systems, with 8 or more yarn feeders, weaving is divided into outer layer B and inner layer A;

[0024] (2) Knitting the top part of the outer hat, the knitting width of the starting needle is N, the direction of the machine head is from left to right, and the front and rear needle beds are used to knit alternately, the machine head runs from position a to position b, and the machine head rotates fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com