Layered pouring construction technology for mass concrete pile cap

A mass concrete, layered pouring technology, applied in construction, infrastructure engineering and other directions, can solve problems such as easy cracking, improve the pouring quality, the overall structure of the cap is firm and reliable, and improve the effect of capping cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

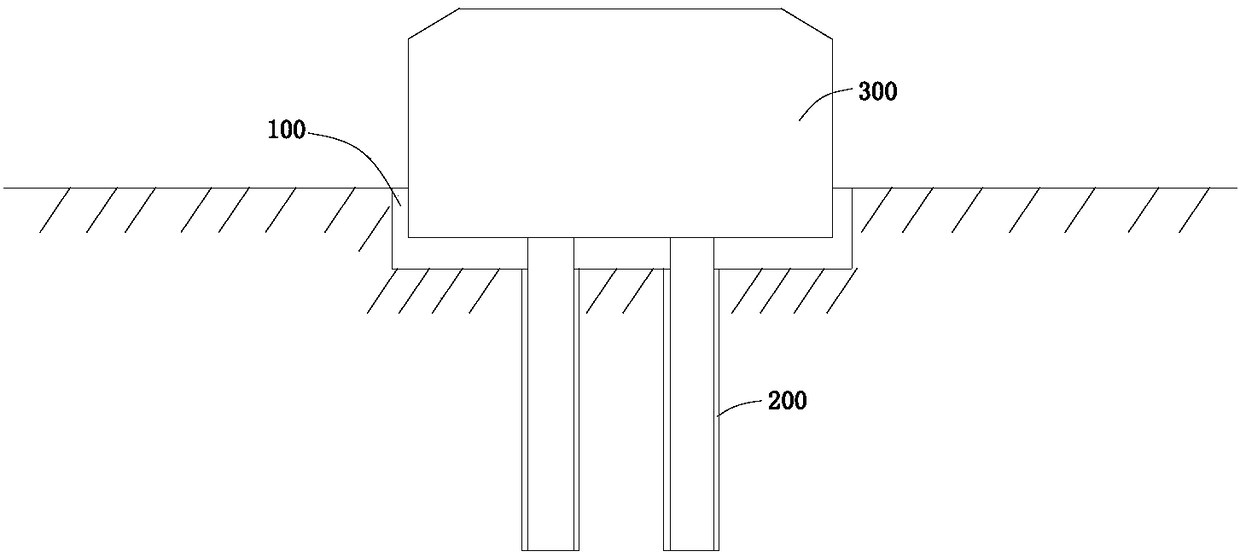

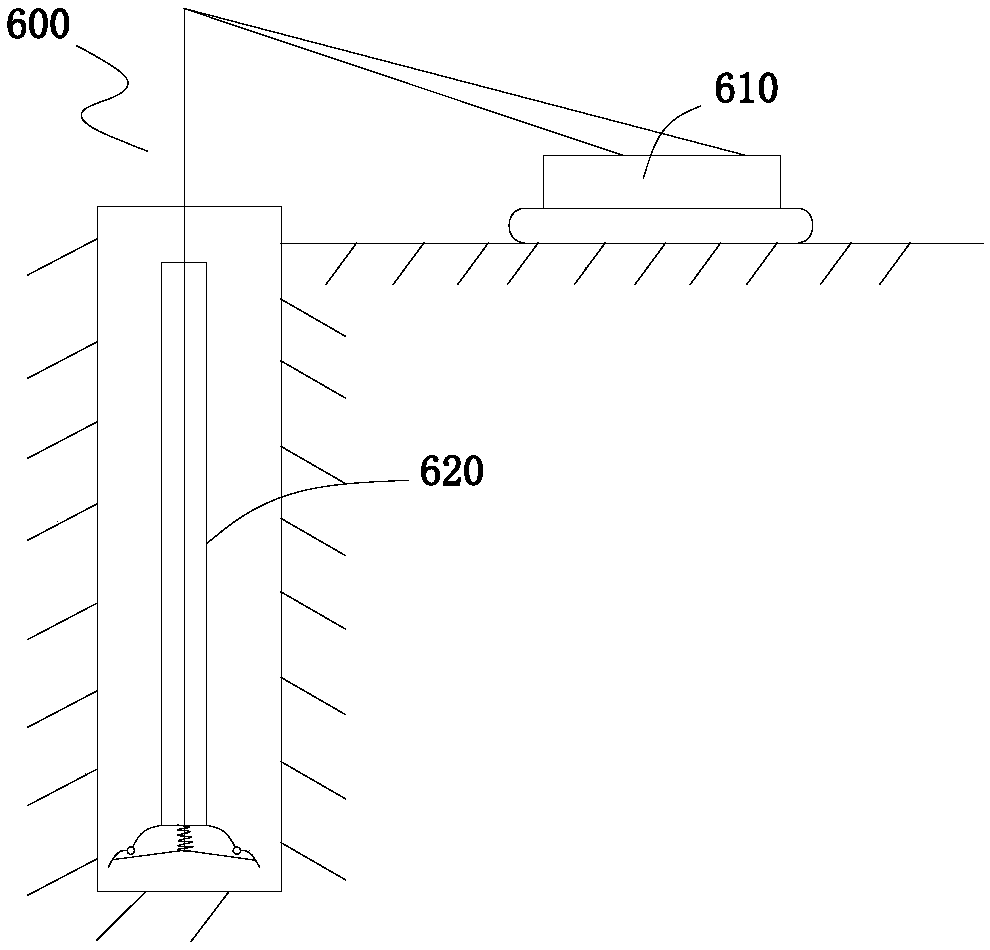

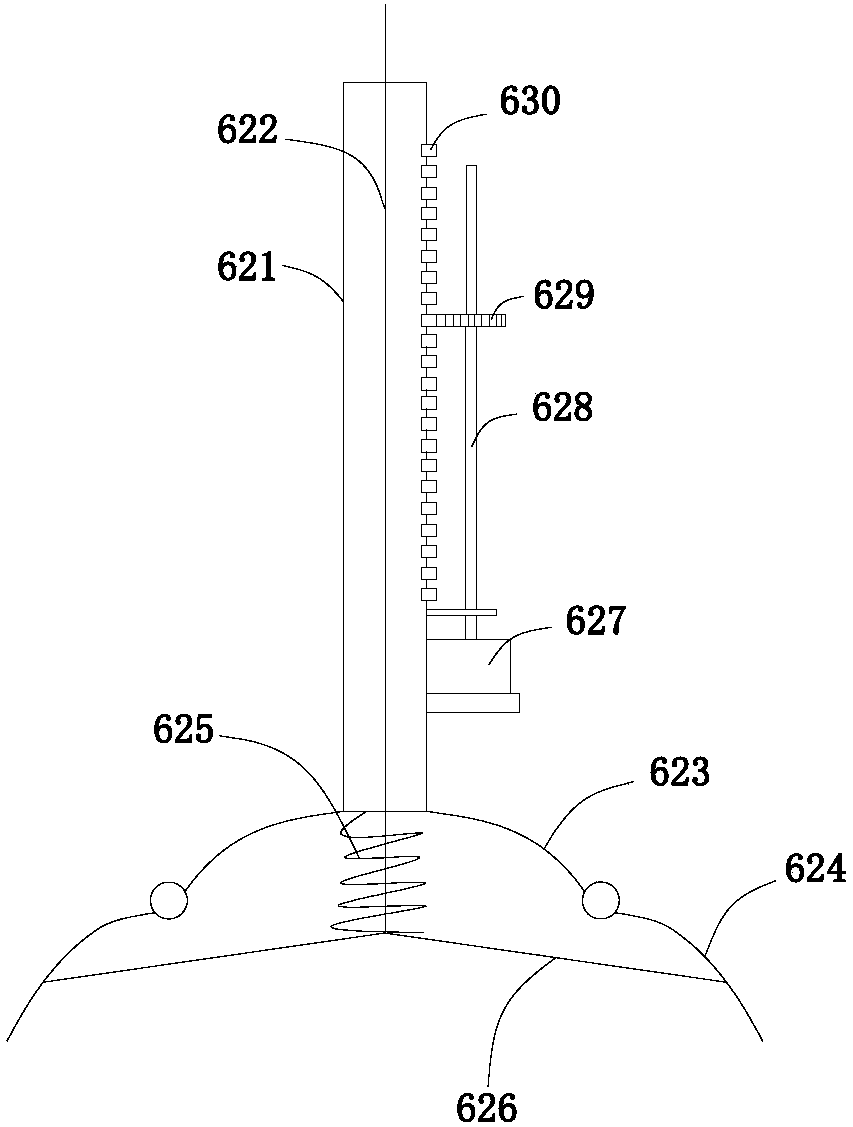

[0044] see figure 1 - Figure 4 , the present embodiment provides a layered pouring construction process for large-volume concrete caps, the construction process includes:

[0045] Step 100. Excavate the foundation pit 100 at the set position, and mark the set position according to the design drawings to improve the accuracy of the excavation of the foundation pit 100. You can use lime to mark, or use ink line marks, etc. . During the excavation process of the foundation pit 100, the protective function of the surrounding walls of the foundation pit 100 should be well protected to prevent the foundation pit 100 from collapsing, improve safety, and improve construction quality. Specifically, protective walls may be provided at the surrounding walls of the foundation pit 100 .

[0046] Step 200, excavate at least one reinforcement hole 200 at the bottom of the foundation pit 100, the reinforcement hole 200 can be a cylindrical hole, the number of reinforcement holes 200 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com