Slope drainage trench design method and application and drainage trench

A design method and technology of drainage ditches, applied in waterway systems, water supply devices, sewer pipe systems, etc., can solve problems such as unreasonable slopes, drainage groove sections, and failure to reach, so as to improve governance, avoid material waste, increase The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a design method for a slope drainage ditch, which includes:

[0030] S1. The position of the preset drainage groove, the drainage groove includes a horizontal drainage groove and a vertical drainage groove, and the horizontal drainage groove and the vertical drainage groove are connected.

[0031] Wherein, in a preferred embodiment of the present invention, the basis for the preset location of the drainage ditch is the rainfall in the area where the slope is located, the soil quality of the area where the slope is located, and the slope angle of the slope. Wherein, the rainfall in the area where the slope is located can be obtained by querying existing data, and the soil quality and slope angle of the area where the slope is located are measured according to existing methods and equipment, and will not be described in detail here.

[0032] S2. (1) Obtain the calculated flow rate due to rainfall accumulation on the control slope of the lateral dr...

Embodiment 2

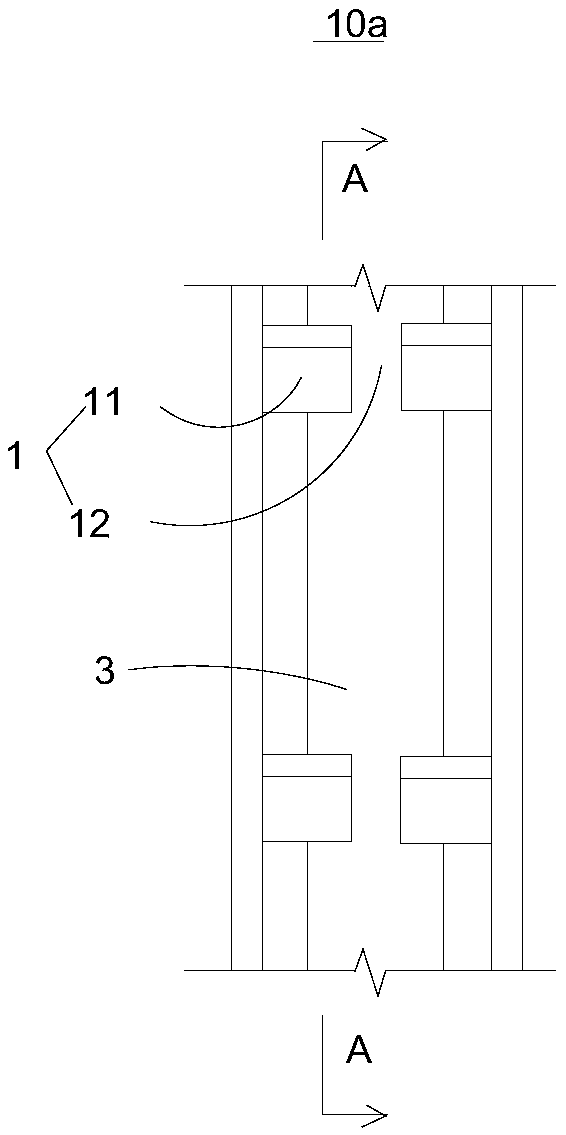

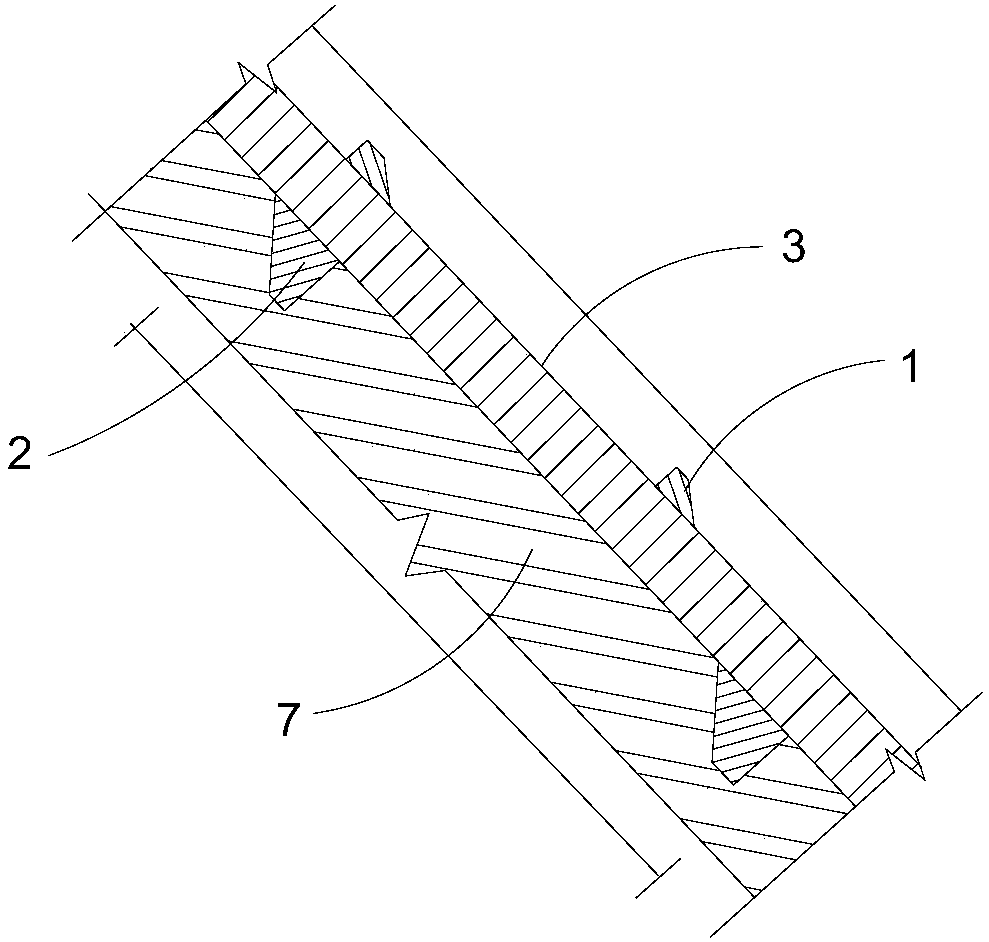

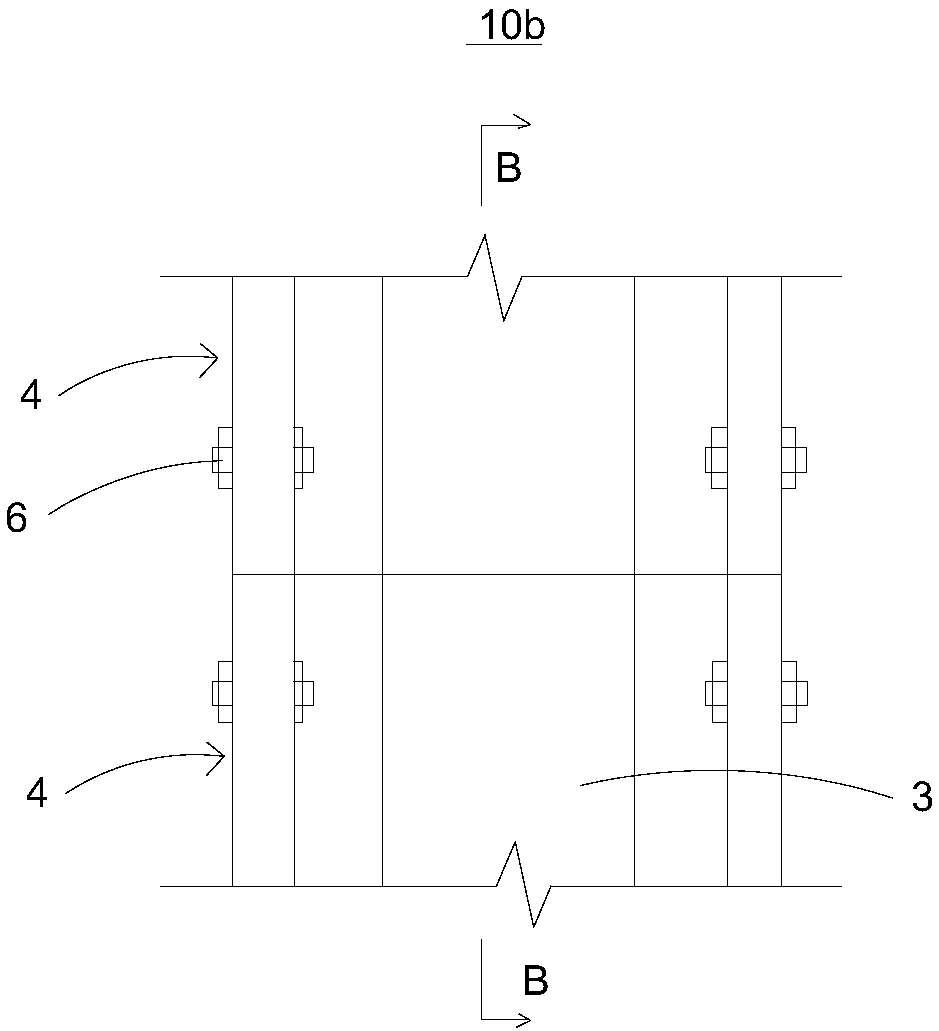

[0084] see figure 1 as well as figure 2 , the present invention also provides a drainage ditch (not shown in the figure), which is designed according to the design method of the above-mentioned slope drainage ditch. The drainage groove includes a vertical drainage groove 10a arranged vertically. The vertical drainage groove 10a is arranged on the slope 7 with the same slope as the slope 7. The vertical drainage groove 10a is provided with a water retaining ridge 1 and an anti-slip ridge 2 .

[0085] The water-retaining sill 1 is arranged on the bottom wall 3 of the longitudinal drainage groove 10a along the longitudinal direction of the longitudinal drainage groove 10a. The cross-section of the water-retaining sill 1 is trapezoidal. The width of the side of the water retaining sill 1 close to the bottom wall 3 of the longitudinal drainage groove 10a is greater than the width of the side of the water retaining sill 1 away from the bottom wall 3 of the longitudinal drainage gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com