Sludge suction vehicle applied in deep sewage well

A technology of sewage suction trucks and water wells, applied in the field of sewage suction trucks, can solve the problems of long time consumption, polluted air, and difficulty in cleaning and transporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

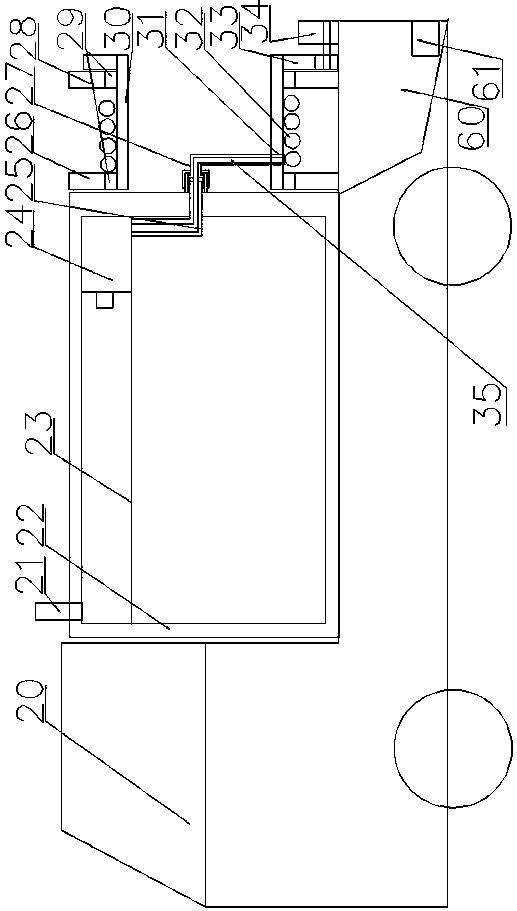

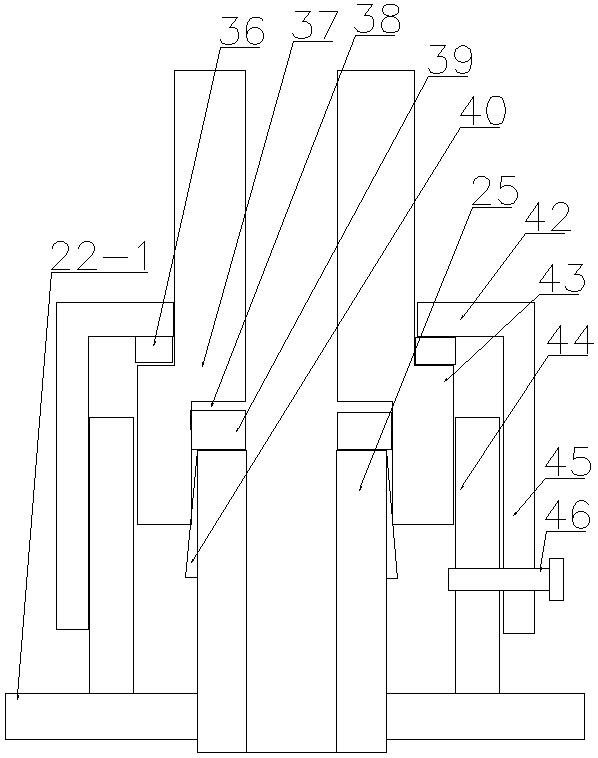

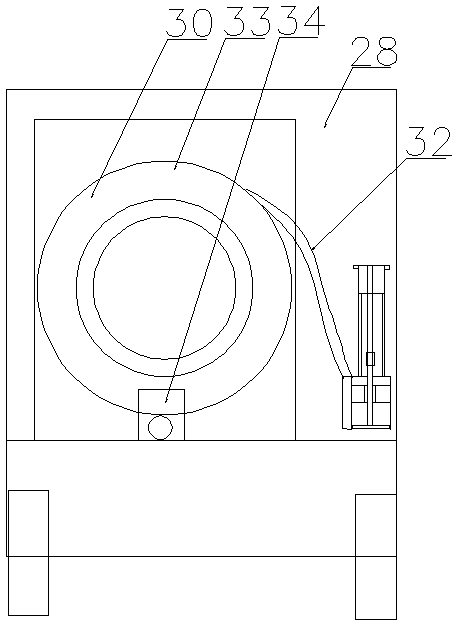

[0032] Embodiment 1: as Figure 1-7 As shown, a sewage suction truck applied to deep sewer wells includes a sewage suction truck 20 and a liquid storage tank 22 arranged on the sewage suction truck 20, the sewage suction pump is located in the liquid storage tank, and the sewage suction pump 24 is located in the The upper part of the filter screen 23, the upper part of the liquid storage tank is provided with a cleaning door, which is convenient for removing the solids on the filter screen, and the filter screen is arranged obliquely to facilitate the removal of the solids; the sewage inlet pipe 25 of the sewage suction pump 24 passes through the liquid storage On the side wall of the tank, the sewage inlet pipe is coaxial with the reel. One side of the liquid storage tank is provided with a main support plate 26 and a secondary positive support plate 28. Both the main support plate and the secondary positive support plate are provided with circular shaft holes. , the circular...

Embodiment 2

[0044] Embodiment 2: as figure 2 , 3 , 4, a sewage suction truck applied to deep sewer wells, comprising a sewage suction truck 20 and a liquid storage tank 22 arranged on the sewage suction truck 20, the sewage suction pump is located in the liquid storage tank, and the sewage suction pump 24 is located on the upper part of the filter screen 23, and the upper part of the liquid storage tank is provided with a cleaning door, which is convenient for removing solids on the filter screen, and the filter screen is arranged obliquely, which is convenient for cleaning out the solids; the sewage suction pipe 25 of the sewage suction pump 24 passes through The side wall of the liquid storage tank, the sewage inlet pipe 25 is coaxial with the reel, the side of the liquid storage tank 22 is provided with a main support plate 26 and a secondary positive support plate 28, and the main support plate and the secondary positive support plate are provided with Circular shaft hole, a bearing 2...

Embodiment 3

[0055] Embodiment 3: A sewage suction vehicle applied to deep sewer wells, including a sewage suction vehicle 20 and a liquid storage tank 22 arranged on the sewage suction vehicle 20, the sewage suction pump is located in the liquid storage tank, and the sewage suction pump 24 Located on the upper part of the filter screen 23, the upper part of the liquid storage tank is provided with a cleaning door, which is convenient for removing solids on the filter screen, and the filter screen is arranged obliquely to facilitate cleaning out the solids; the sewage suction pipe 25 of the sewage suction pump 24 passes through the storage tank. The side wall of the liquid tank, the sewage inlet pipe is coaxial with the reel, and the main support plate 26 and the auxiliary positive support plate 28 are arranged on one side of the liquid storage tank, and the main support plate and the auxiliary positive support plate are both provided with circular shafts A bearing 29 is arranged in the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com