Bending and shearing separation type prefabricated assembly-type frame column and construction method thereof

A prefabricated assembly and separate technology, applied in the direction of construction, building structure, etc., can solve the problem that the detection level of grouting density can not guarantee the quality of connection, etc., to achieve easy control of connection quality, easy maintenance and inspection, and convenient construction and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

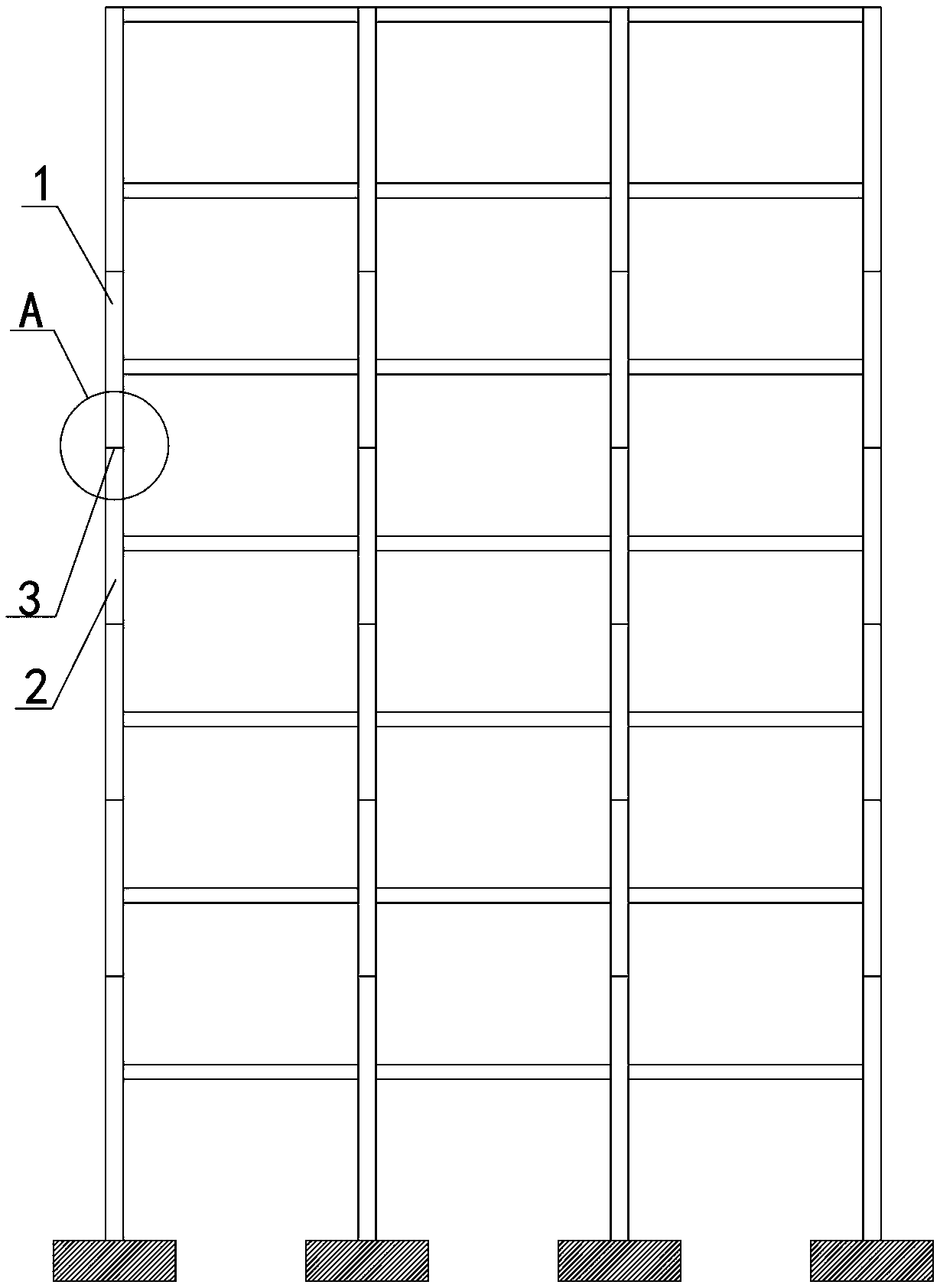

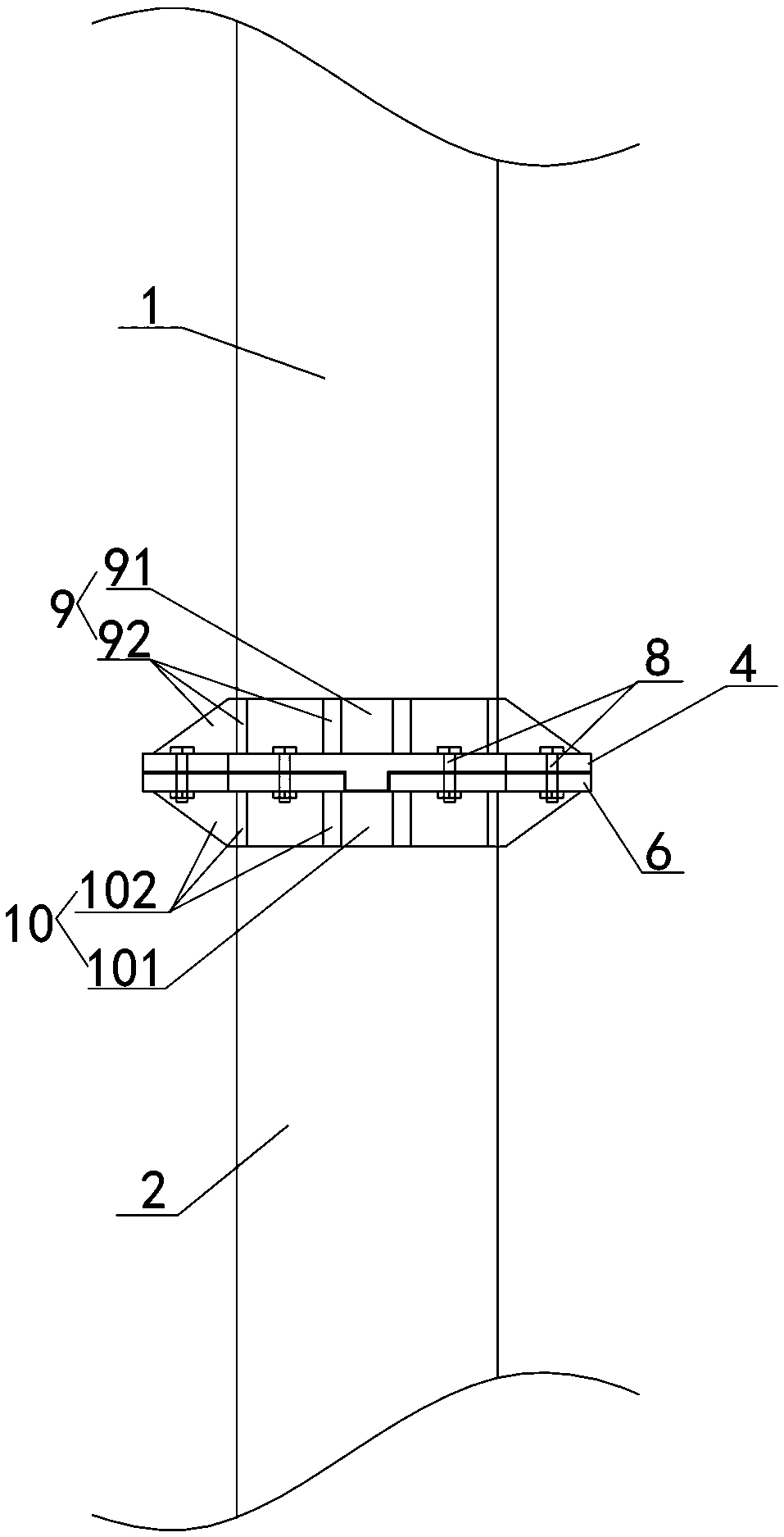

[0044] Examples see Figure 1-6 As shown, a bending-shear separated prefabricated frame column includes a group of precast concrete column sections spliced up and down. The column sections include an upper column section 1 and a lower column section 2. 3 at the bending moment inversion point between the layers and the middle of the column section.

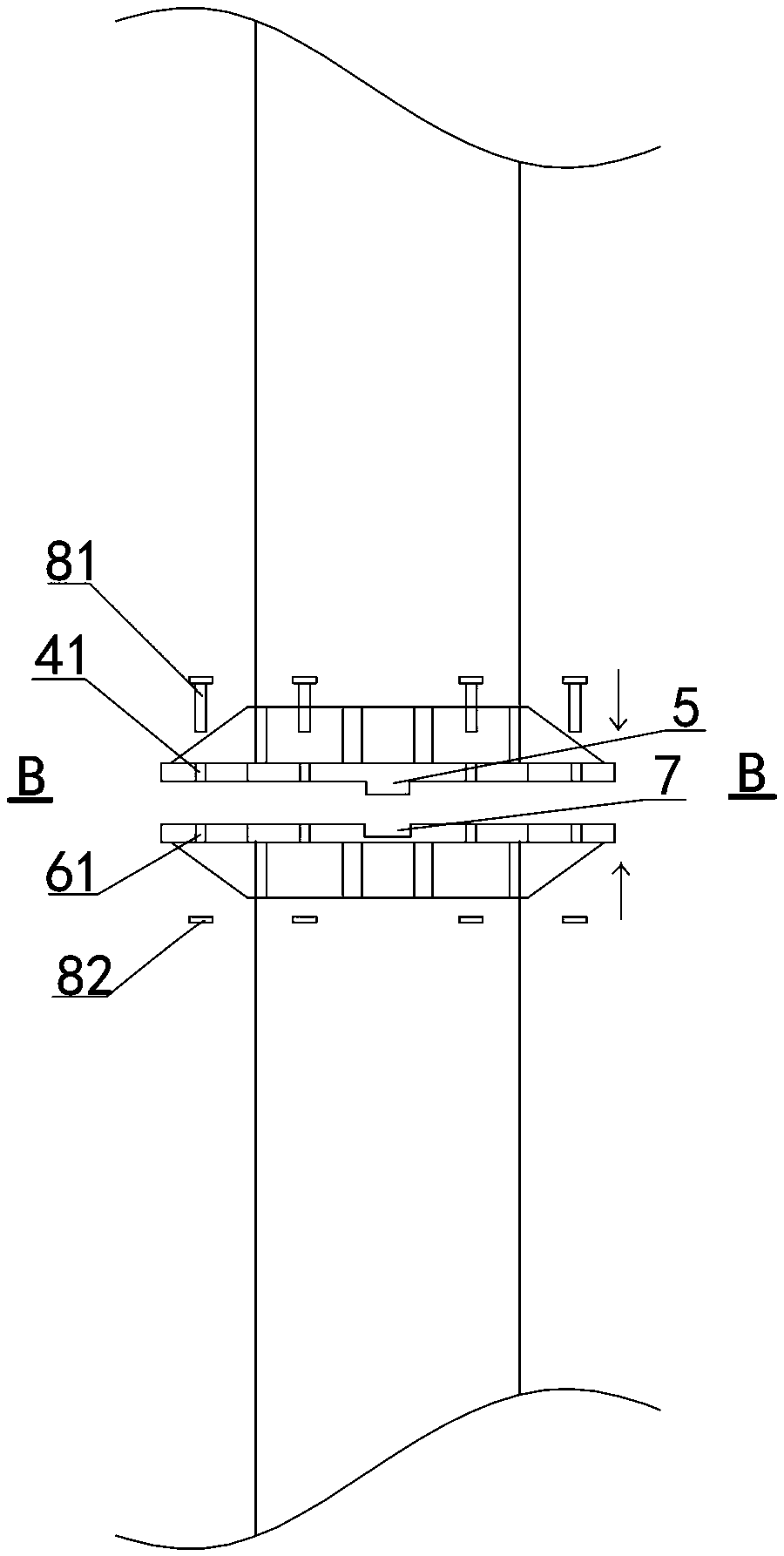

[0045] The bottom end surface of the column section is pre-embedded with a horizontal bottom steel sealing plate 4, and the center of the bottom steel sealing plate 4 coincides with the center of the cross section of the column section. The lower convex shear key 5. The shear key 5 and the bottom steel seal plate 3 are integrally machined and formed, and the shear key 5 is centrally symmetrically arranged on the bottom steel seal plate 3, and is a bump and a convex line located in the center of the bottom steel seal plate Or a combination of both. In this embodiment, it is a bump arranged in the center.

[0046] The top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com